Our machines

| Model | Width (m) | Weight (kg)* Share bolt protection | Weight (kg)* Spring protection | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|---|

| POV3 | 0.6 - 1.5 | 1100 | 1300 | 90 - 120 | 3 | 0.8 - 1.3 | 30 |

| POV4 | 0.8 - 2.0 | 1350 | 1550 | 120 - 140 | 4 | 1.0 - 1.7 | 30 |

| POV5 | 1.0 - 2.5 | 1600 | 1800 | 140 - 180 | 5 | 1.2 - 2.0 | 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

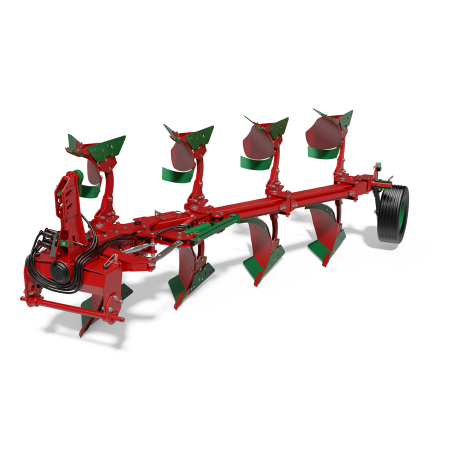

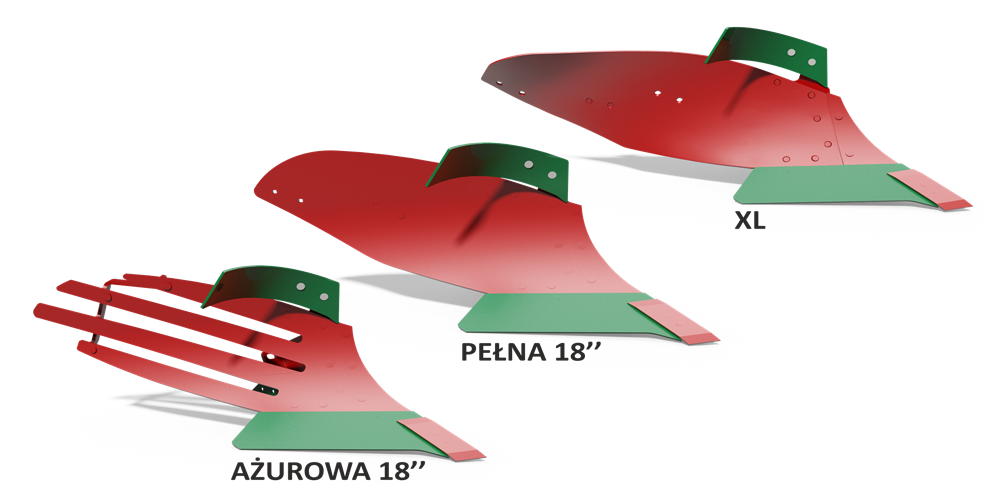

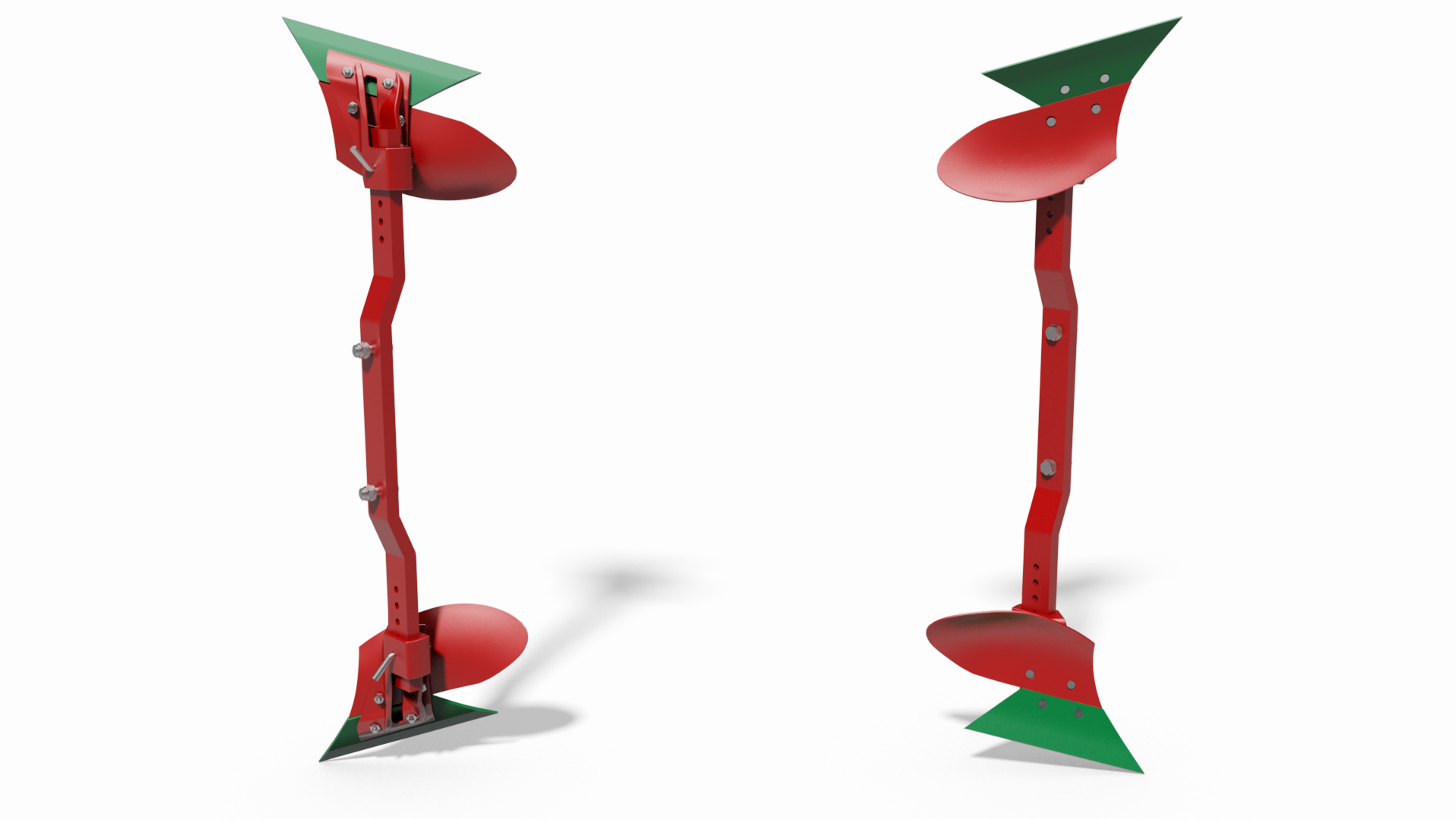

POV is the latest plow of our production. We equipped this machine with the VARIO system, which ensures easy use of the plow. This technology enables smooth independent adjustment of the working width and pulling point. The modern solutions used in this machine mean that regardless of the working width set, the plow cannot stand the tractor sideways.

The future of your crop production direction is safe with robust and efficient machines, and inexpensive. The PO series of plows gives you the certainty of a quick return on costs, allowing you to focus on crops. The rotary plow concept is part of the idea of efficient and fast plowing without unnecessary downtime. While developing the concept of rotary plows, AGRO-MASZ designers focused on the use of the latest technical solutions available, such as a thermally improved frame and construction based on bolted joints to extend the life of the machine. It guarantees reliability for a long time.

Reliability and efficiency - these are not all the advantages of our plows. The use of high-strength steel gave us the opportunity to create an extremely durable and light plow. The frame (profile 140 x 140 mm) made of steel with improved parameters, thermally improved, ensures that the plow will cope even in difficult conditions.Adequate clearance under the frame of 76 cm and body spacing of 100 cm guarantee coverage of even a significant amount of crop residues and catch crops. Our experience, opinions of satisfied customers and continuous tests allow us to create new solutions, which results in the next generation of rotary plows.

The new head design of the second generation rotary plows meets the growing requirements. The plow will cope with difficult conditions cooperating with new types of tractors. Maintenance-free operation for years is due to the rotation spindle with increased diameter made in patented technology, mounted on a system of twin needle bearings. The rotation cylinder located behind the turret is responsible for the smooth rotation of the plow. Thanks to the lightweight design and optimal transfer of the machine's center of gravity, the rotation is carried out very quickly without disturbing the stability of the set.

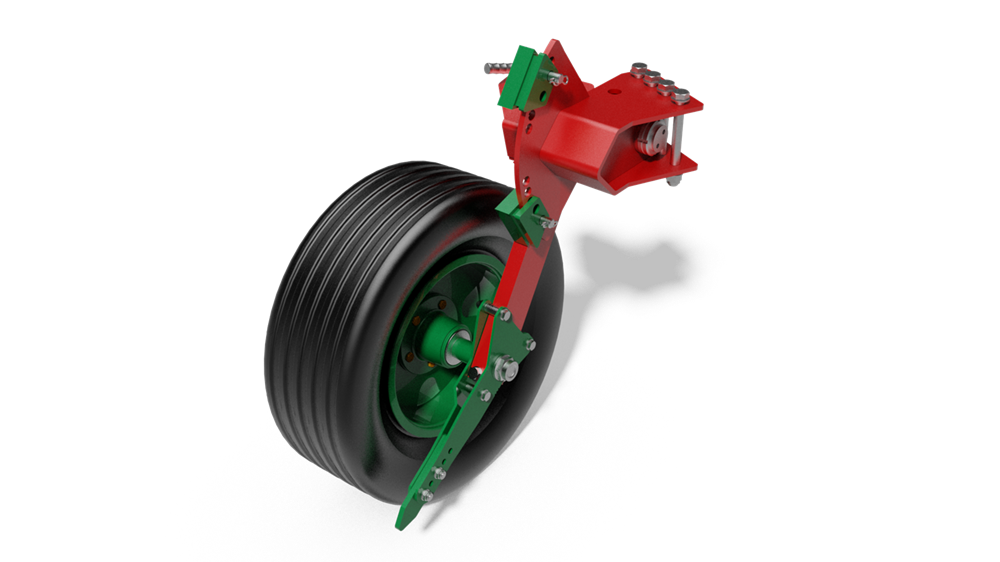

Do not hesitate if you will commute to the field along rough roads or even with even surfaces. All POV plows from our offer can be equipped with a transport and copying wheel mounted behind the last body. The plow located in a half-turn position, guided along the road, stands firmly on the wheel, which allows the machine to be driven safely at transport speeds allowed for the agricultural tractor. The plow head has an ergonomic transport safety device guaranteeing stable running of the plow behind the tractor. A strong rubber wheel mounted behind the last working section of the plow stabilizes the operation of the machine and reliably maintains the set working depth limited on the adjustment scale by means of steel cubes.

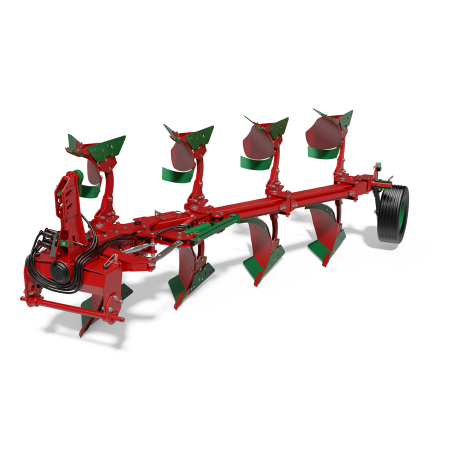

Our bodies work even at speeds of up to 10 km / h. The work of each body gives the effect of even furrow edges with full inversion of each furrow, even with a large amount of organic residues. Much of this is due to the cylindrical-screw type depot, which puts little resistance additionally significantly reducing fuel consumption. The bodies are also great at crushing larger lumps of soil. As standard, shear bars mounted on each body work on soils with a large amount of crop residues, without reducing the clearance between the bodies, as in the case of using skimmers, and thus do not cause the risk of clogging the machine. You will certainly appreciate the simple screw regulation of the depot and the angle of attack of the whole body, especially when you set low fuel consumption as a determinant of effective work.

When plowing fallow land, meadows or pastures, extension slats mounted on mouldboards are extremely useful.

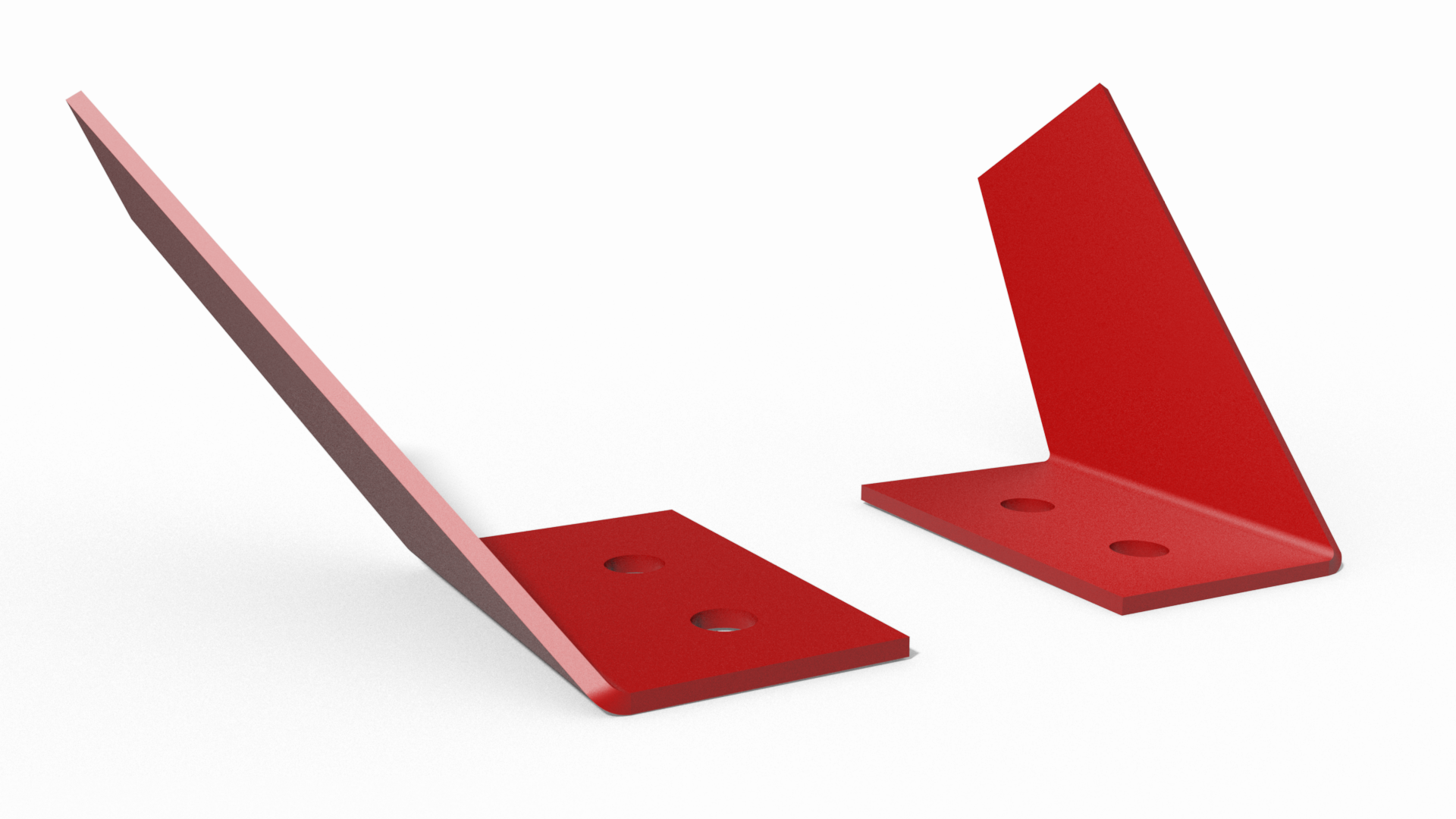

More and more often chosen by farmers as a cheaper replacement for the disc cut.

To achieve the fullest effect of mixing with the soil and covering crop residues, the plow can be equipped with a set of skimmers. Determining the optimal position of their work is possible thanks to multi-step adjustment. The position of the skimmers is easily changed by means of an adjustment screw, which blocks the position of the skimmer. Each skimmer has universal and popular overload protection in the form of a break screw. Each individual handle of the skimmer is mounted to the main body pocket, which guarantees that the working geometry of the skimmer will be identical to the work characteristics of the body on which it is mounted. Skimmers are particularly well suited to working on corn stubble. When the user decides that the use of shear bars gives a satisfying effect, he can quickly dismantle the skimmers and return to the previous configuration.