Our machines

| Model | Width (m) | Weight (kg) * | Power demand (HP) | No. of plates (pcs) | Performance (ha/h) | Working depth max (cm |

|---|---|---|---|---|---|---|

| TIGER8 | 8.0 | 8500 | 270 - 330 | 64 | 9.6 - 12 | 14 |

| TIGER10 | 10.0 | 9500 | 330 - 400 | 80 | 12 - 15 | 14 |

*The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

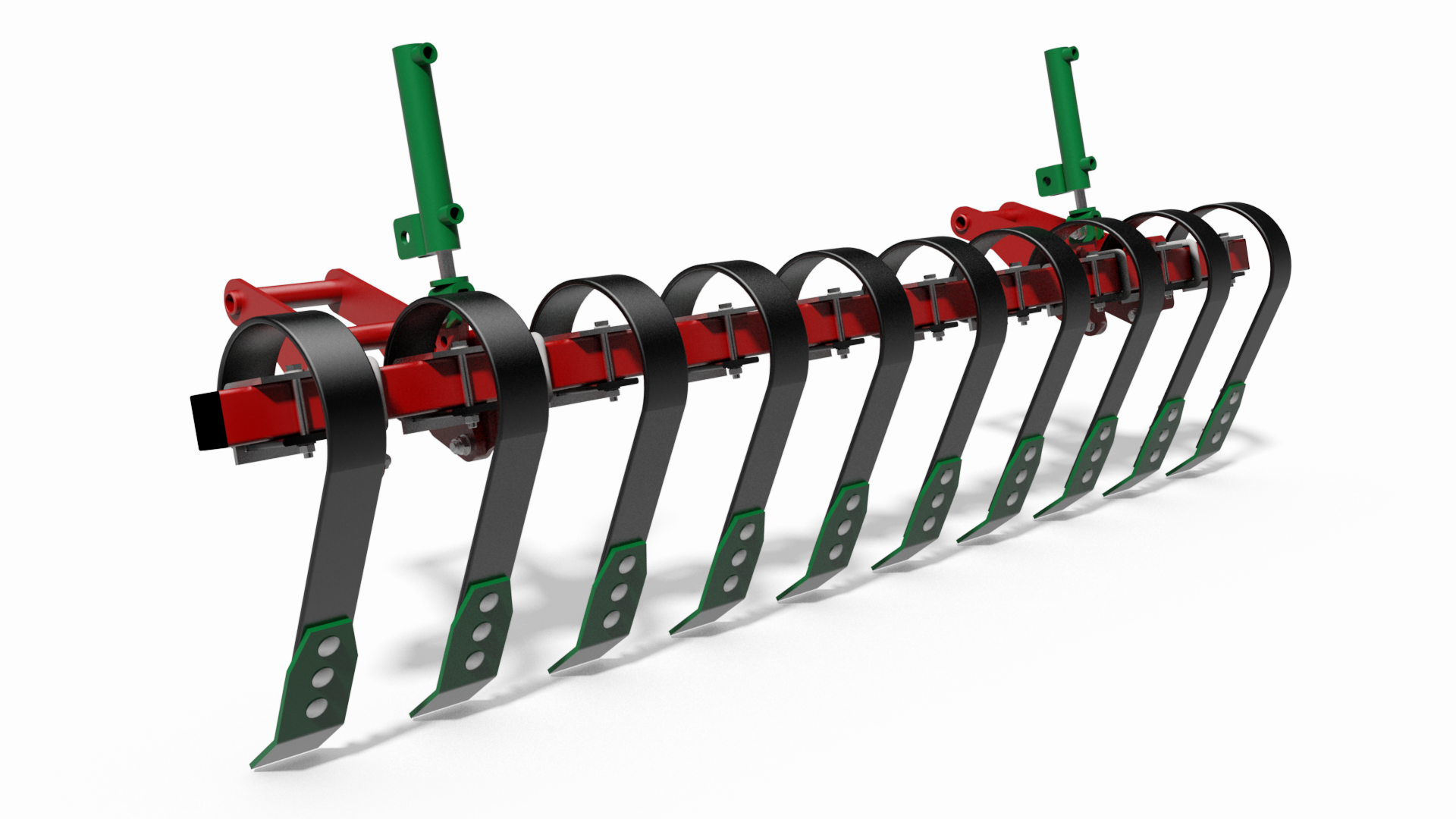

Semi-mounted disc harrows are machines designed for difficult tasks. They allow for intensive and quick stubble cultivation. They are efficient with low fuel consumption at the same time. TIGER harrows are great at dealing with stubble with a large amount of crop residues, as well as restoring fallow land for use.

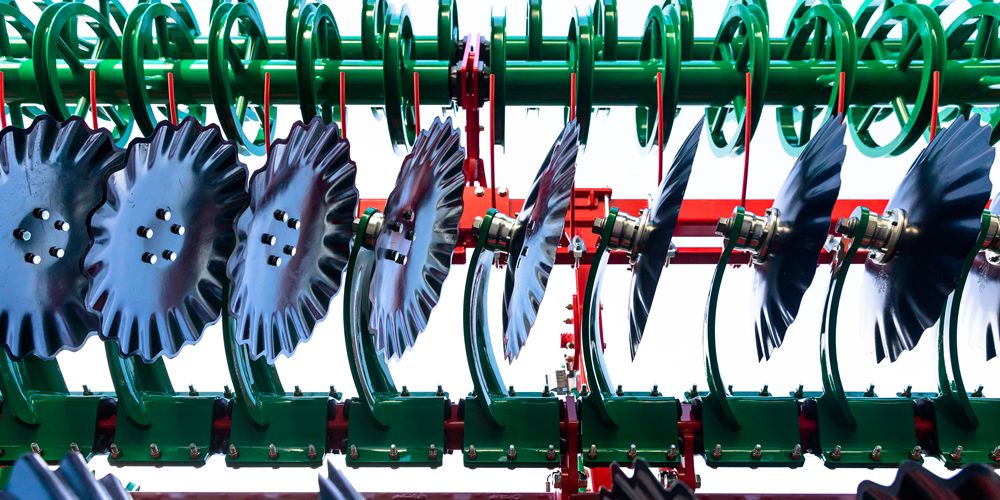

The time that the operator has to spend on the daily maintenance of the set has been reduced to a minimum. You can forget about bearing lubrication. Our disc harrows are equipped with hubs as standard maintenance-free, at the heart of which are bearings identical to those used in the automotive industry. The entire system is secured with cassette sealants, which are most effective in tough field work conditions.

Active screens located on the edge of both disc sections limit the area of soil depositing by the edge discs, preventing the formation of ruts at the connections of the passages. In the event of an excessive depression or encountering a large obstacle, the screen holders are attached to the frame by means of floating connections, which allow the screens to tilt upwards during a collision. So you don't have to adjust the screen, it will adapt itself to the conditions. Additionally, you can adjust its depth and longitudinal position.

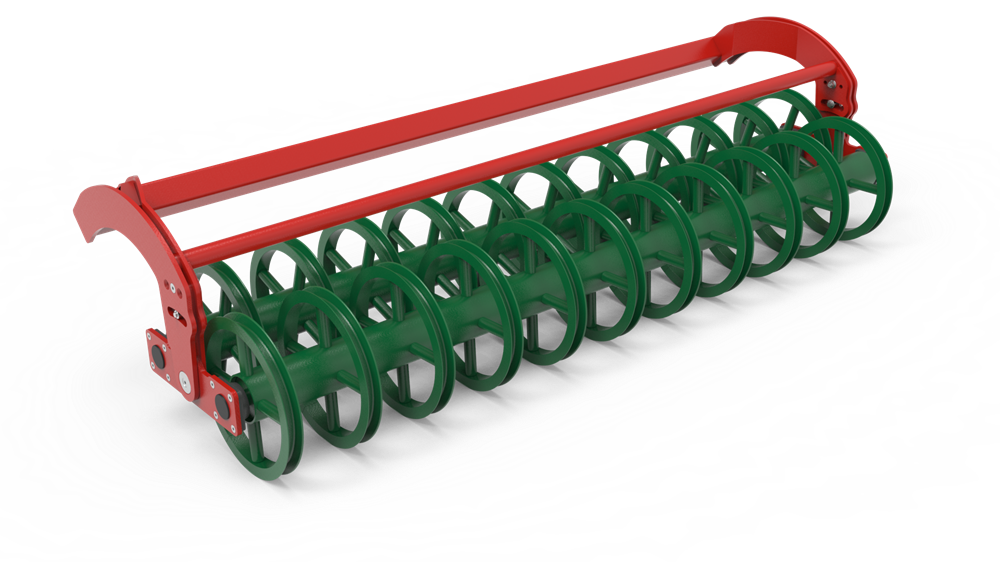

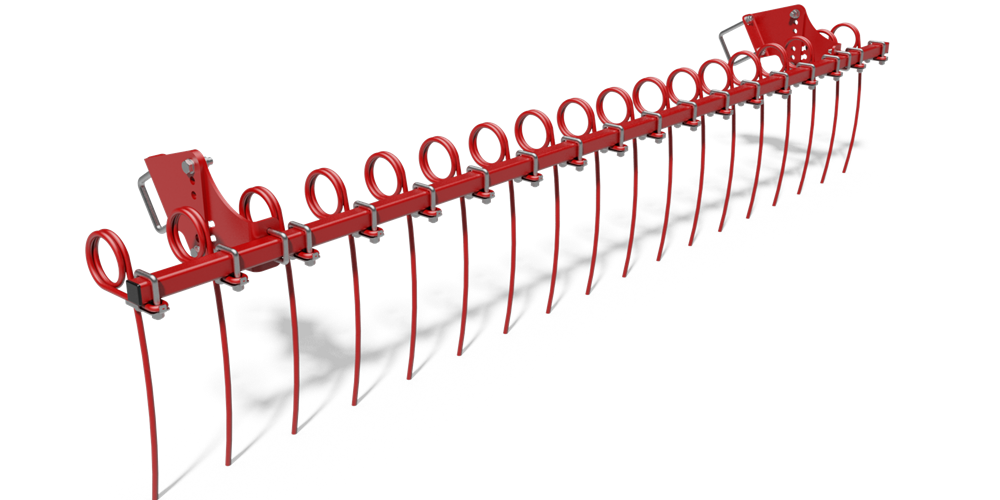

The best effect of crushing the soil and its leveling on the surface is achieved by the work of the comb. After one working pass, the soil is prepared for sowing.