Our machines

| Model | Working width (m) | Weight (kg)* | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| PO2 | 0.70-1.00 | 1000 | 70-100 | 2 | 0.56-0.8 | 30 |

| PO3 | 1.05 - 1.50 | 1050 | 80 - 115 | 3 | 0.8 - 1.3 | 30 |

| PO4 | 1.40 - 2.00 | 1300 | 115 - 140 | 4 lub 3+1 | 1.0 - 1.7 | 30 |

| PO5 | 1.75 - 2.50 | 1550 | 130 - 180 | 5 lub 4+1 | 1.2 - 2.0 | 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

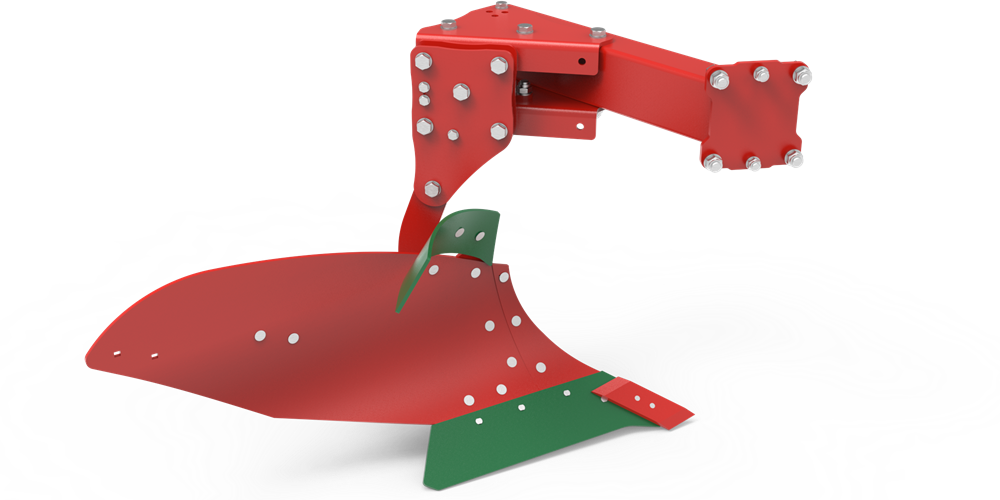

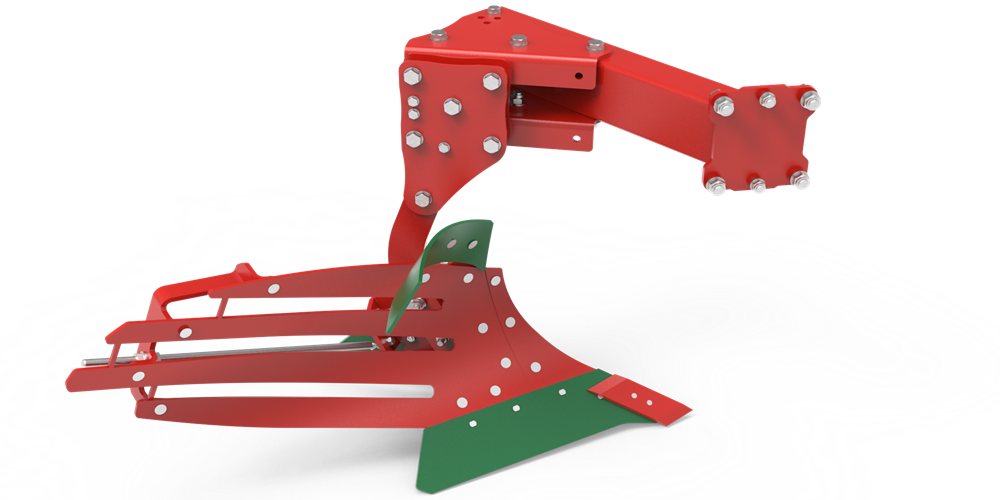

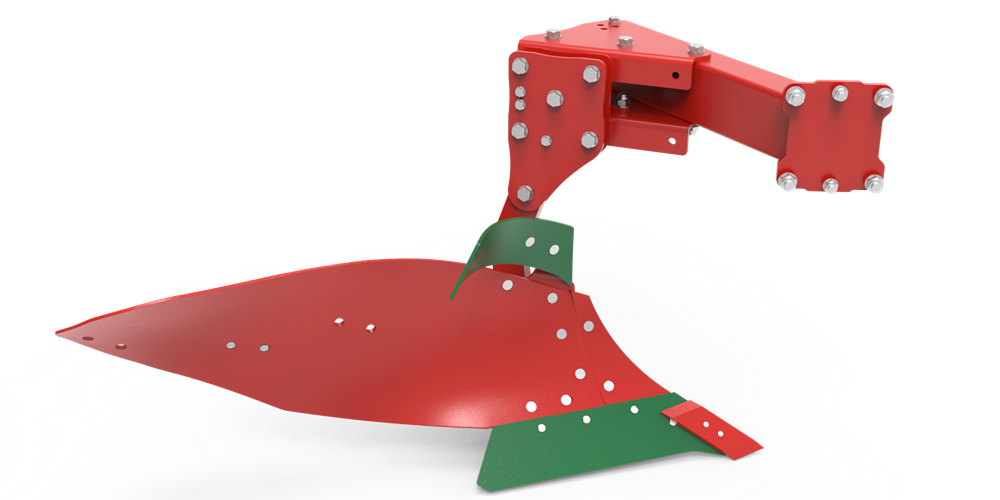

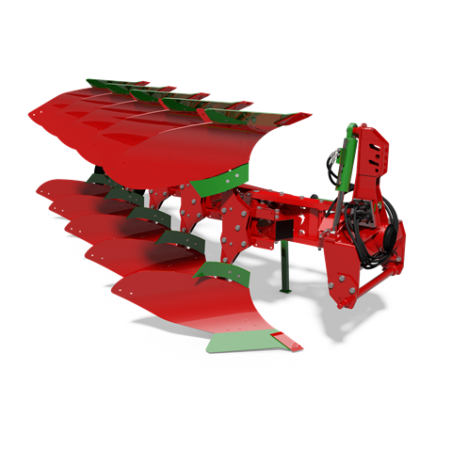

Reliability and ease of use enclosed in a solid construction. Our plows combine these features and will certainly meet your requirements. Appropriate 76 cm clearance under the frame and body spacing (85 cm or 100 cm to choose from) guarantee covering even a significant amount of crop residues and catch crops. The use of high-quality steel allowed for a very durable construction with the lowest total weight of the machine in its class. The frame (profile 140 x 140 mm) made of steel with improved parameters, thermally improved, ensures that the plow will cope even in difficult conditions. Our experience, opinions of satisfied customers and continuous tests allow us to create new solutions, which results in the next generation of rotary plows.

The plowing capacity and the level of combustion of the tractor depend largely on the working width of the plow. You can easily change the plowing width in our plows by changing the position of the adjusting screw, which determines the working width of each furrow. Without unnecessary effort, you adjust the working width of the plow to the power and type of tractor. The four-stage scale of step adjustment of the width of each body with 35, 40, 45, 50 cm width offers great possibilities. The reduction in width may be caused by changing soil conditions. You can also increase the width to the maximum if you want to do a shallow plowing. Tractor power and parameters can also be fully used in very variable conditions.

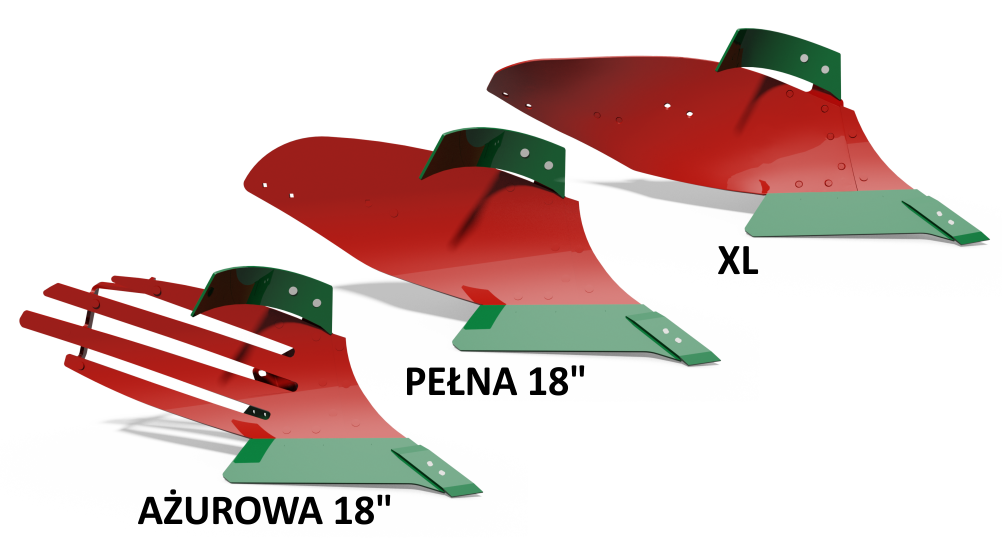

Designed to test in deep plowing from 15 to 35 cm for working widths in the range 35 - 50 cm for each furrow. Our bodies work even at speeds of up to 10 km / h. The work of each body gives the effect of even edges of furrows with full inversion of each furrow, even with a large amount of organic residues. Much of this is due to the cylindrical-screw type depot, which puts little resistance, significantly reducing fuel consumption. The bodies are also great at crushing larger lumps of soil. As standard, shear bars mounted on each body work on soils with a large amount of crop residues, without reducing the clearance between the bodies, as in the case of using skimmers, and thus do not cause the risk of clogging the machine. You will certainly appreciate the simple screw regulation of the depot and the angle of attack of the whole body, especially when you set low fuel consumption as a determinant of effective work.

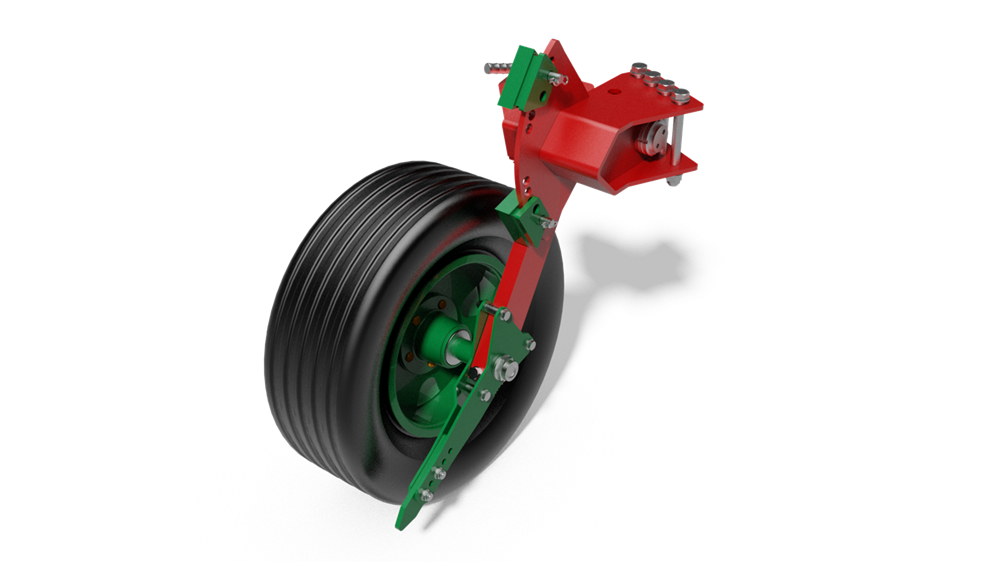

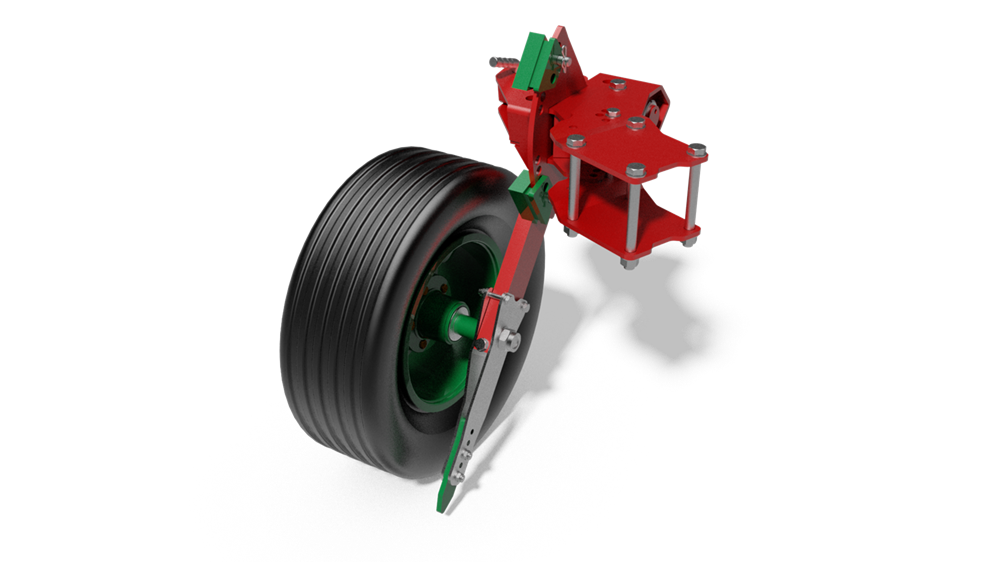

Why do you have to worry about the stability of the plow during road transport and calculate the weight of the ballast for the front axle of the tractor? Do not hesitate if you will commute to the field along rough roads or even with even surfaces. All PO plows from our offer can be equipped with a transport and copying wheel mounted behind the last body. The plow located in a half-turn position, guided along the road, stands firmly on the wheel, which allows the machine to be driven safely at transport speeds allowed for the agricultural tractor. The plow head has an ergonomic transport safety device guaranteeing stable running of the plow behind the tractor. A strong rubber wheel mounted behind the last working section of the plow stabilizes the operation of the machine and reliably maintains the set working depth limited on the adjustment scale by means of steel cubes.

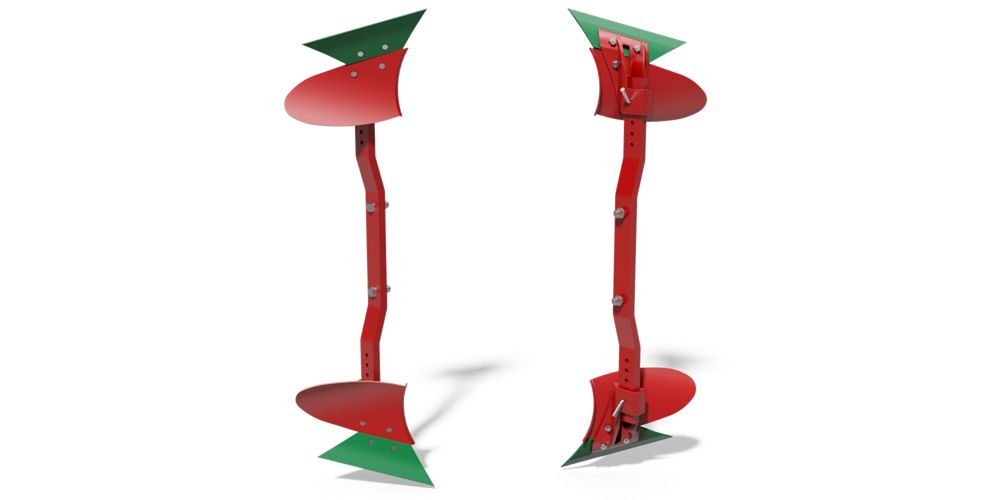

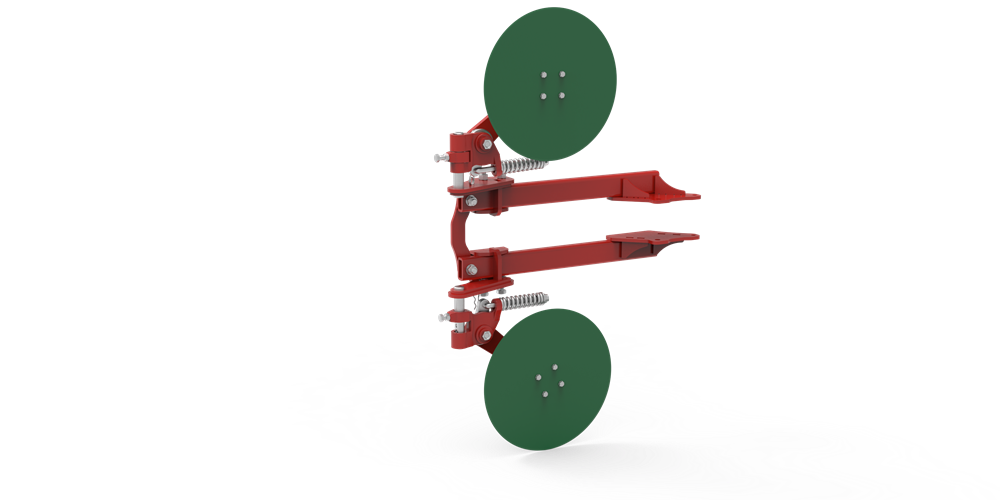

The corrugated disks with a diameter of 500 mm both for the models with bolt and suspension spring protection improve significantly the visual effect of the plough work. While separating a furrow-slice from the undisturbed soil the disk coulters determine the most exact turnover of the furrow-slice leaving a clean furrow with smooth walls. The coverage effect of the agricultural crop residues is increased as a result of the operation of the coulters as well. Just like all working elements the coulters are also protected against damage in the heavy soil conditions. In this case the protection is realised by a spring with adjustable pressure force. However, the optimum working position of the disk coulter can be achieved by means of toothed adjusting blocks.

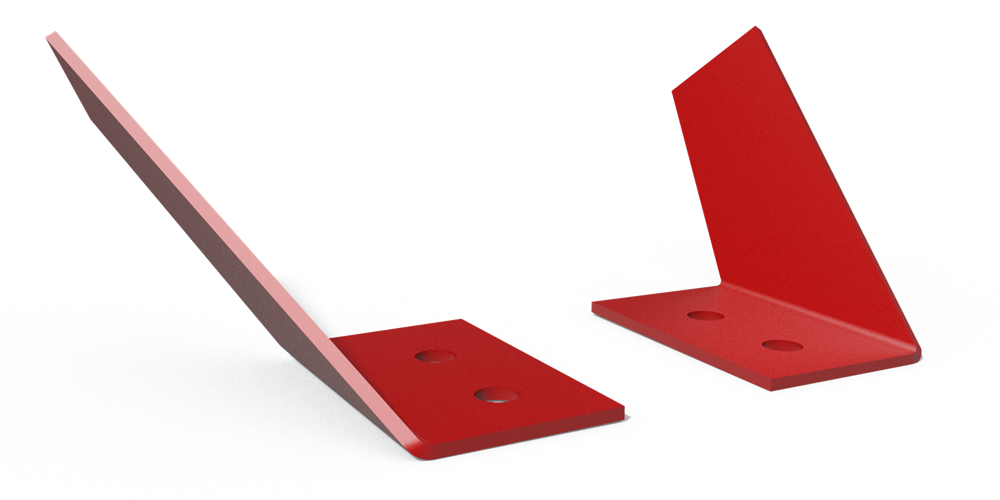

When plowing fallow land, meadows or pastures, extension slats mounted on mouldboards are extremely useful.

More and more often chosen by farmers as a cheaper replacement for the disc cut.

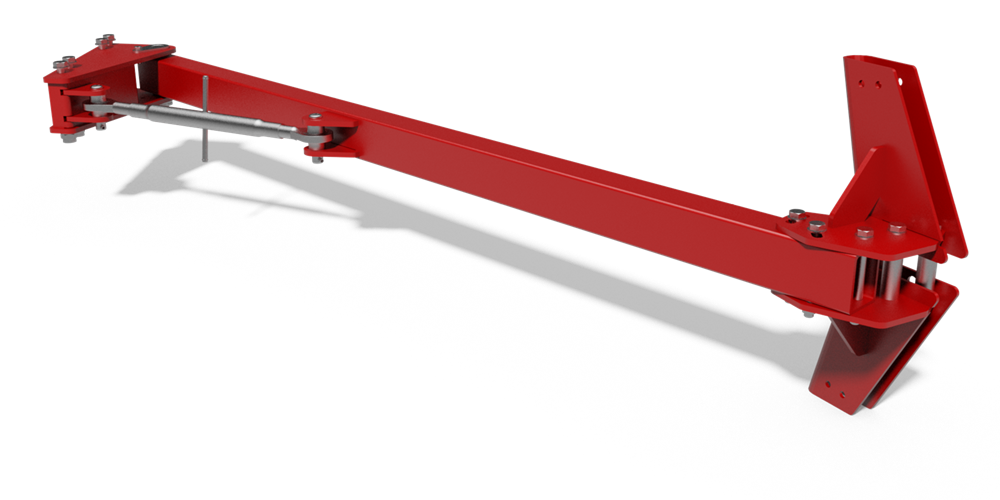

As part of one pass, we carry out plowing and secondary soil compaction while crushing large lumps of soil, leaving the field well prepared for subsequent treatments. The shaft arm is adjustable and the shaft coupling/uncoupling is automatic.