Our machines

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| PO3 | 1.05 - 1.50 | 1050 | 80 - 115 | 3 | 0.8 - 1.3 | 30 |

| PO4 | 1.40 - 2.00 | 1300 | 115 - 140 | 4 or 3+1 | 1.0 - 1.7 | 30 |

| PO5 | 1.75 - 2.50 | 1550 | 130 - 180 | 5 or 4+1 | 1.2 - 2.0 | 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

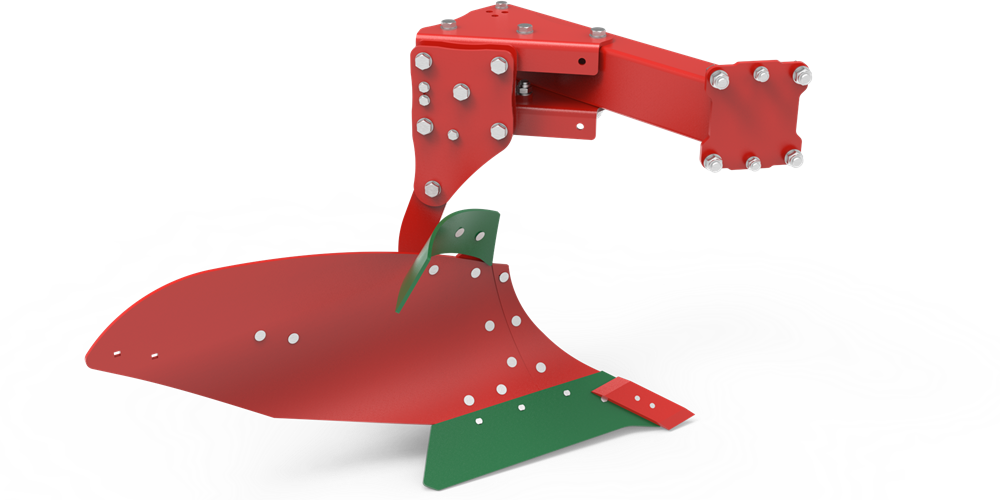

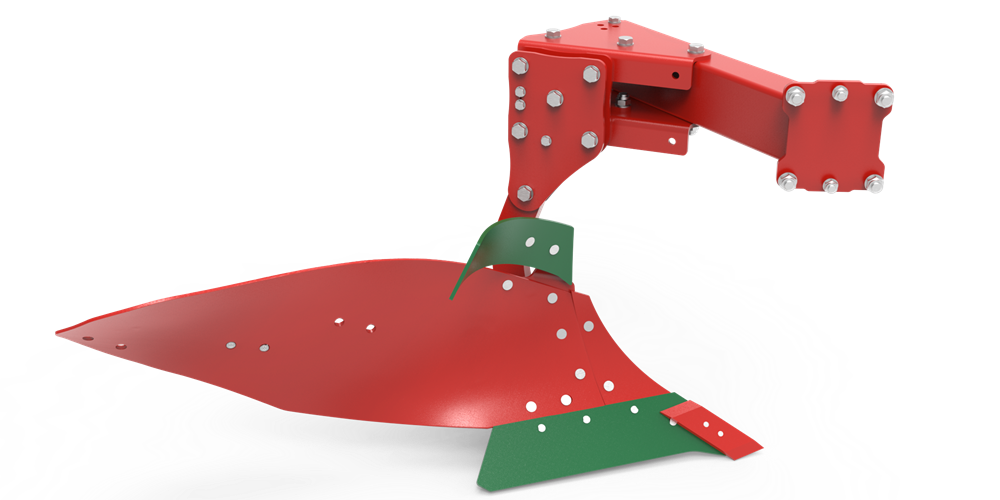

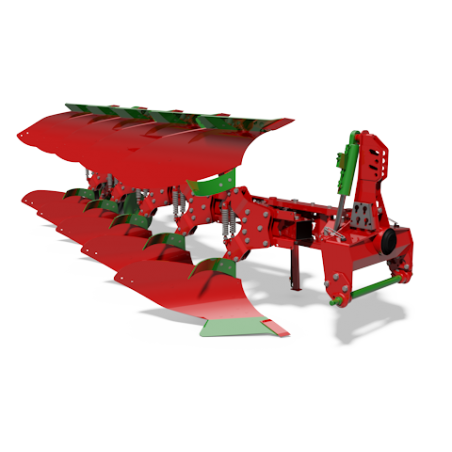

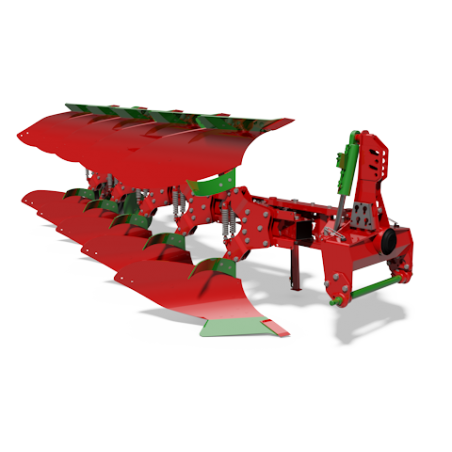

The operation reliability and simplicity closed in a solid design. Our ploughs combine these features and they will certainly meet your requirements. The proper ground clearance under the frame of up to 76 cm and the spacing of the bodies (of up to 85 cm or 100 cm) guarantee the coverage of significant amounts of agricultural crop residues and secondary crops. The use of the high quality steel let obtain a very durable design at the total machine mass the least in its class. The frame (140x140 mm profile) made of improved and heat-treated steel ensures that the plough manages even in the heavy conditions. Due to our experiences, satisfied customers’ opinions and continuous tests we can create new solutions which lead to the next generation of rotary ploughs.

It is only one direction, i.e. to limit the production costs. The future of the direction of the plant production that you have selected is safe with the solid, effective and not expensive machines. The PO series ploughs ensure a fast return of the incurred expenses and allow focusing on the crops. The conception of rotary plough is consistent with an idea of effective and quick ploughing without unnecessary downtime. Ploughing is the first agricultural measure. This is just the beginning of the road. Hit the road only with the experienced partner. Go ahead with us. AGRO-MASZ engineers developing the conception of rotary ploughs focused on using the latest available technical solutions, such as the heat-treated frame and the design based on the bolted connections for the extension of the machine lifetime which guarantees reliability for a long time.

A light design means lower fuel consumption, so low costs at the beginning. Furthermore, the long lifetime of the working subassemblies ensures low operational costs. AGRO-MASZ uses advanced steel processing technologies in the production of its ploughs in order to obtain the optimum durability of working subassemblies. The difference is invisible to the eye but it is tangible with every hour of the work in the field.

The ploughing performance and tractor combustion level depend to a large extent on the working width of the plough. The ploughing width in our ploughs can be changed in a simple manner, by shifting the position of adjusting bolt which determines the work width of every furrow-slice. The working width of the plough can be adjusted to the tractor power and type without unnecessary efforts. The four-stage scale of the gradual work width adjustment of every body within 35, 40, 45, 50 cm gives huge opportunities. The width reduction can be forced by changing soil conditions. The width can be also increased to the maximum when shallow ploughing is required. The tractor power and parameters can be fully used in very changing conditions as well.

An angle of plough inclination is set separately for every side. A simple arrangement of the bolts located by the machine head guarantees the uniform work of the left and right bodies. The set work position (angle) of the left and right bodies is locked by securing the hinged holders.

A new design of the head of the second generation of the rotary ploughs meets the increasing requirements. The plough comes up with the heavy conditions cooperating with the new types of tractors. The maintenance-free operation for years is attributed to the pivot with an increased diameter, made in the patented technology, seated onto the system of twin needle bearings. The swing cylinder located behind the plough turret is responsible for a smooth rotation of the plough. Due to the light design and the optimum movement of the centre of gravity of the machine the revolution is made quickly without distorting the stability of the assembly. There is a drawbar of the 2nd and 3rd category available for the best adjustment to your tractor. Furthermore, to move optimally the centre of gravity of the plough towards the tractor the bar can be blocked in one of four positions.

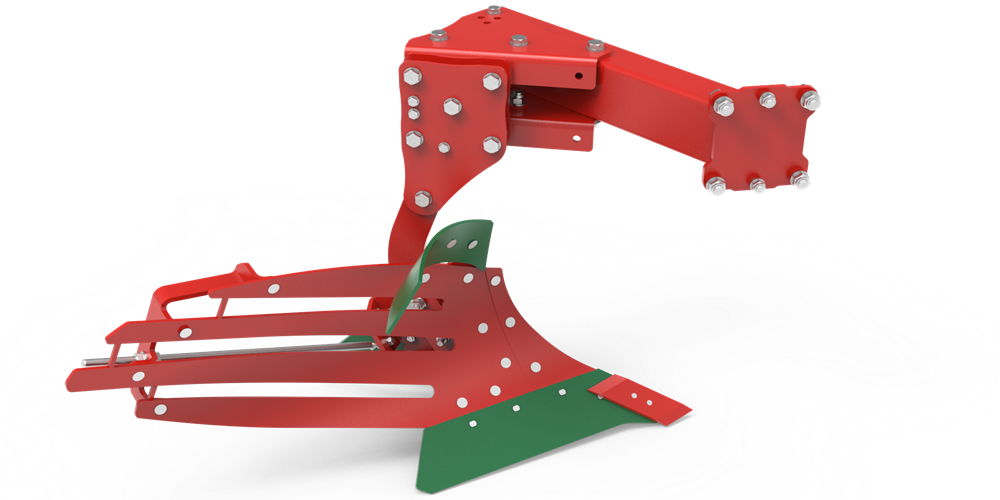

The semi-automatic protection has been the missing link in our offer to this day. The perfect compromise between shear and spring protection. For each type of soil, in conditions of fields not stony or slightly stony.

As for the adjustment we are guided by one principle: simplicity. Only the uncomplicated adjustment systems of the plough parameters allow focusing on the work and not on the verification of the machine operation. The alignment and width adjustment of the first furrow-slice (in the parallelogram system) is performed by means of the turnbuckles. The optimum pulling point is achieved in a simple manner. However, if you prefer the highest level of the operational comfort you can choose a plough with the hydraulic alignment adjustment where the cylinder is equipped with a sequential valve that supports additionally the revolution process, narrowing the machine and transferring the copied adjustment of the plough work from the left-hand bodies to the right-hand bodies and vice versa.

This is the simple adjustment according to our conception.

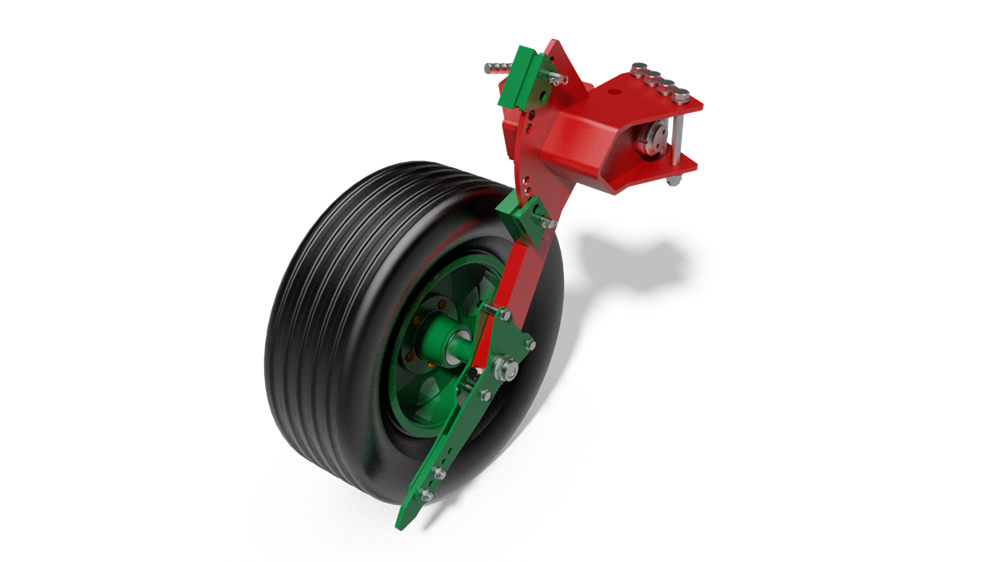

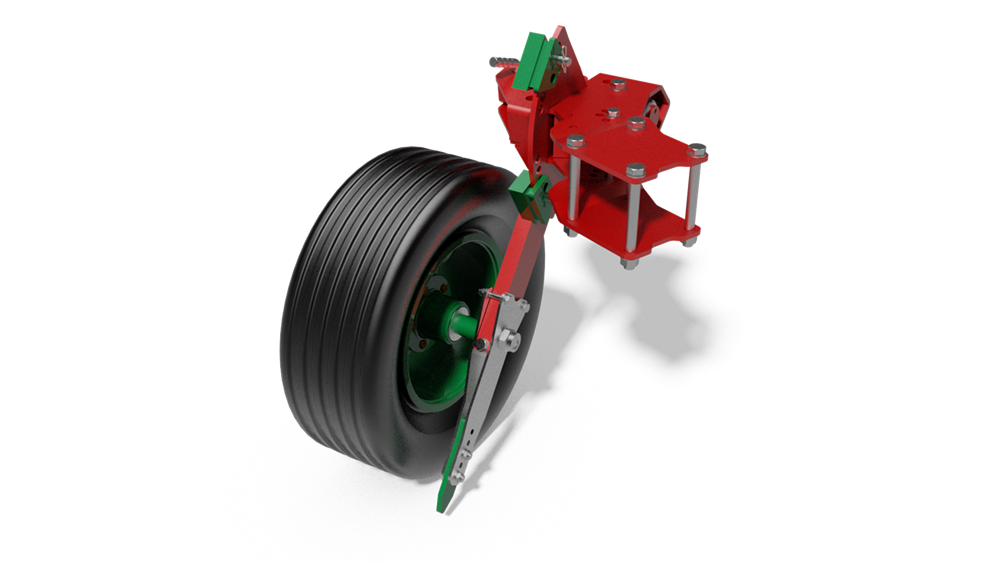

Why should you worry about the stability of the plough during the transport on the roads and calculate the dead weight for the front axle of the tractor? Do not deliberate what kind of roads - with bumpy or even surface - lead to the field. Select our plough! All rotary ploughs we offer are equipped with a depth and transport wheel fastened behind the last body. The plough in a half-turn position operated on the road is supported by the wheel what allows the safe operation of the machine at the transport speeds permitted for the agricultural tractor. The plough head has an ergonomic transport protection that ensures the stable transport of the plough behind the tractor. The strong rubber wheel fastened behind the last working section of the plough stabilises the machine operation and maintains firmly the set working depth limited in the adjustment scale by means of steel blocks.

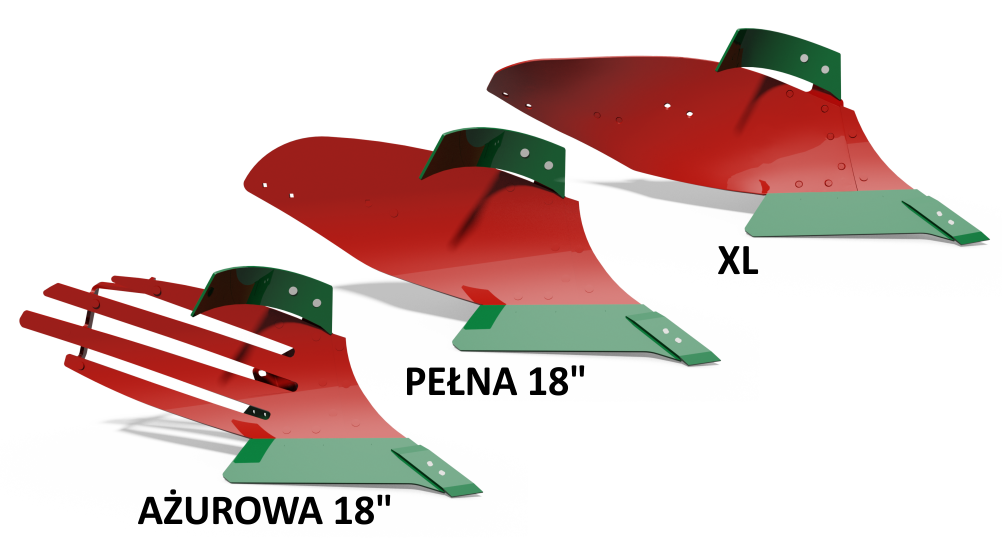

The properly selected steel which the ploughshares are made of allows absorbing stresses arising ruing the work. This feature, combined with the proper wear resistance, determines that our ploughshares fulfil excellently their role. The two-edged chisels are installed on the ploughshares. They undergo a special thermal treatment which extends their service lifetime. When one edge is worn the chisel can be turned by 180° when both edges are worn the chisel can be replaced with a new one – i.e. equally effective and inexpensive Agro-masz tool. The chisels improve efficiently the work quality in all ploughing conditions. Aspiring to create the most versatile but universal machine we remember to guarantee the possibility of even more full adjustment of our ploughs to the various field conditions. We offer therefore a wide range of additional equipment that can be used to “retrofit” our machines.

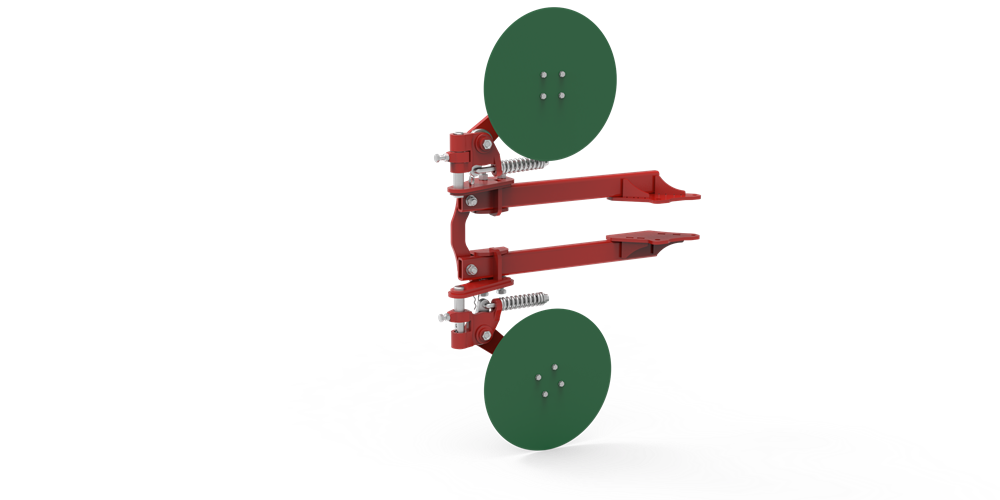

The corrugated disks with a diameter of 500 mm both for the models with bolt and suspension spring protection improve significantly the visual effect of the plough work. While separating a furrow-slice from the undisturbed soil the disk coulters determine the most exact turnover of the furrow-slice leaving a clean furrow with smooth walls. The coverage effect of the agricultural crop residues is increased as a result of the operation of the coulters as well. Just like all working elements the coulters are also protected against damage in the heavy soil conditions. In this case the protection is realised by a spring with adjustable pressure force. However, the optimum working position of the disk coulter can be achieved by means of toothed adjusting blocks.

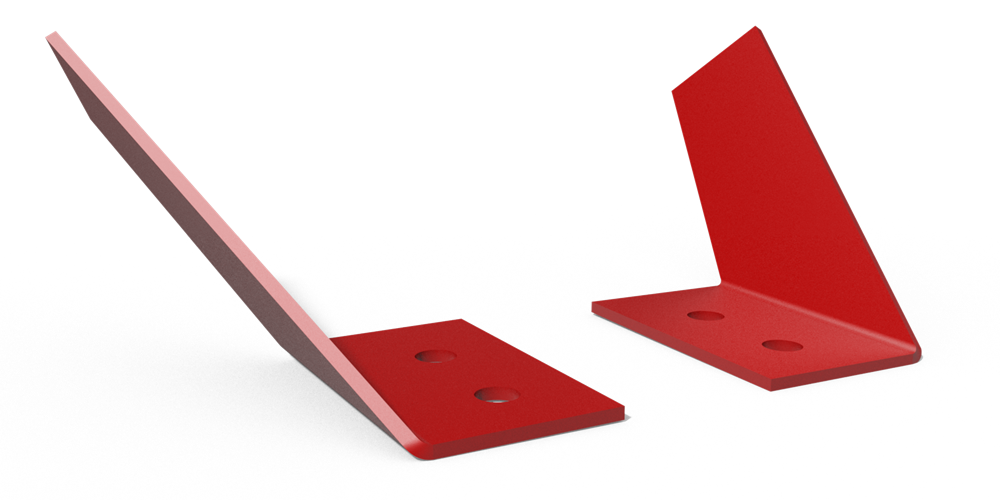

When plowing fallow land, meadows or pastures, extension slats mounted on mouldboards are extremely useful.

More and more often chosen by farmers as a cheaper replacement for the disc cut.

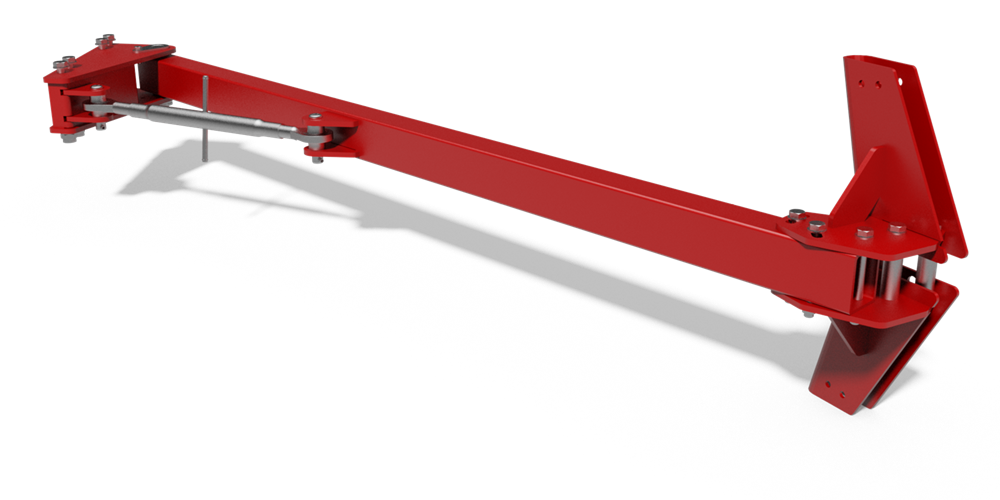

As part of one pass, we carry out plowing and secondary soil compaction while crushing large lumps of soil, leaving the field well prepared for subsequent treatments. The shaft arm is adjustable and the shaft coupling/uncoupling is automatic.

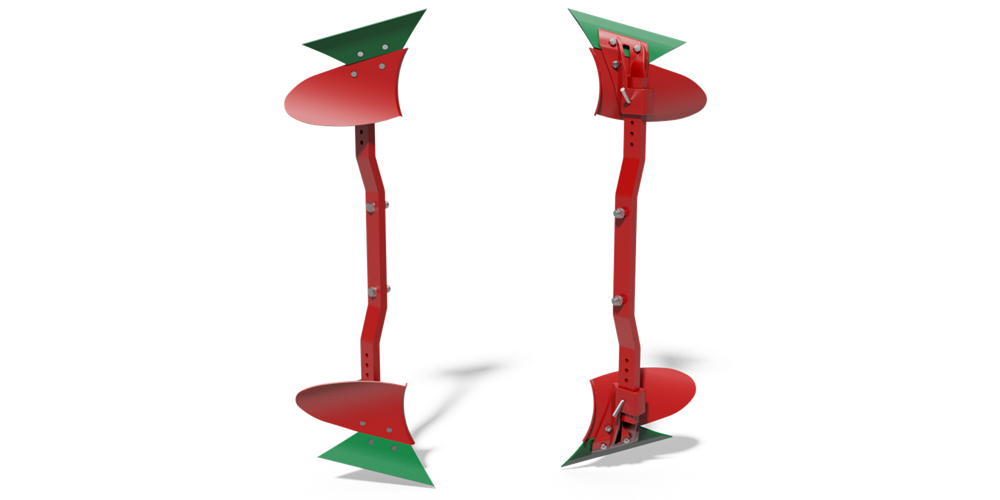

To achieve the fullest effect of mixing with the soil and covering crop residues, the plow can be equipped with a set of skimmers. Determining the optimal position of their work is possible thanks to multi-step adjustment. The position of the skimmers is easily changed by means of an adjustment screw, which blocks the position of the skimmer. Each skimmer has universal and popular overload protection in the form of a break screw. Each individual handle of the skimmer is mounted to the main body pocket, which guarantees that the working geometry of the skimmer will be identical to the work characteristics of the body on which it is mounted. Skimmers are particularly well suited to working on corn stubble. When the user decides that the use of shear bars gives a satisfying effect, he can quickly dismantle the skimmers and return to the previous configuration.