Our machines

| Model | Szerokość (m) | Waga (kg)* | Moc (KM) | Ilość korpusów (szt.) | Wydajność (ha/h) | Głębokość robocza max (cm) |

|---|---|---|---|---|---|---|

| FRONT2 | 0.70 - 1.00 | 1000 | 70 - 105 | 2 | 0.56 - 0.8 | 30 |

| FRONT3 | 1.05 - 1.50 | 1250 | 80 - 115 | 3 | 0.80 - 1.3 | 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

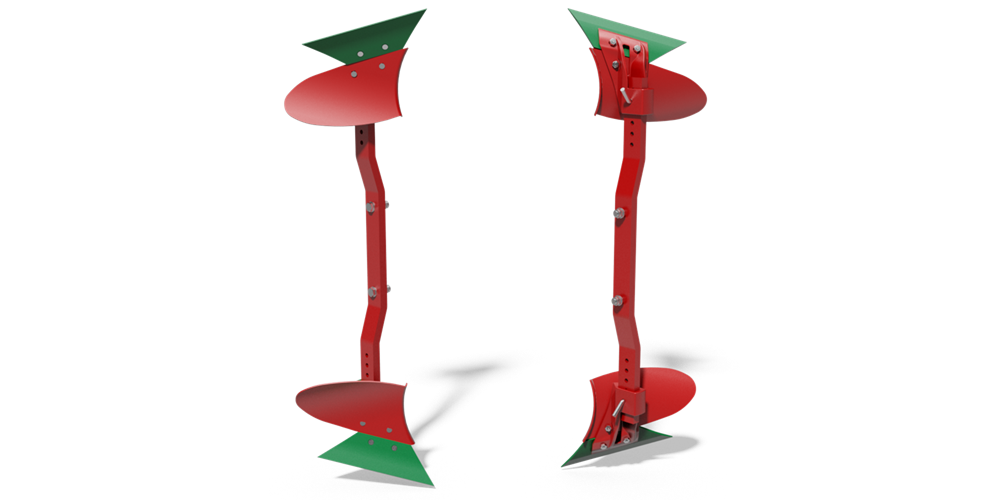

Reliability and ease of use enclosed in a solid construction. Our plows combine these features and will certainly meet your requirements. An adequate clearance under the frame of 76 cm and a body spacing of 100 cm guarantee covering even a significant amount of crop residues and catch crops. The use of quality steel allowed for a very durable construction with the lowest total weight of the machine in its class. The frame (profile 140 x 140 mm) made of steel with improved parameters, thermally improved, ensures that the plow will cope even in difficult conditions. Our experience, opinions of satisfied customers, and continuous tests allow us to create new solutions, which results in the next generation of rotary plows.

The lightweight design means lower fuel consumption, and therefore low start costs. And in conjunction with the long life of the working components, it means low operating costs. AGRO-MASZ uses advanced steel processing technologies to achieve optimal strength of working components in the production of its plows. The difference is invisible to the eye but noticeable with each hour of work in the field.

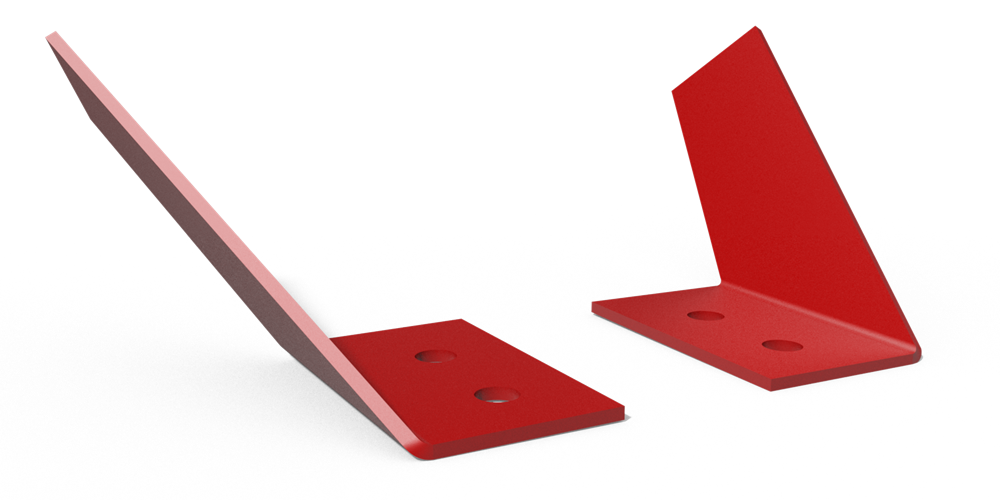

Spring protection of the body works best on soils where the plow would be exposed to frequent shearing of the fuse bolts. Each body independently reacts to obstacles, and the spring allows to minimize the forces arising during a collision and to quickly return the body to the precisely set working position. The unique technology of making articulated points located on the connection of each body with the pocket allows you to lead plowing in almost any conditions without stress. Each spring forms a system of leaves made of spring steel responsible for maintaining the position of the bodies and their deflection in the event of a force acting on the blade which exceeds that set on the adjustment bolts. Efficient and simple.

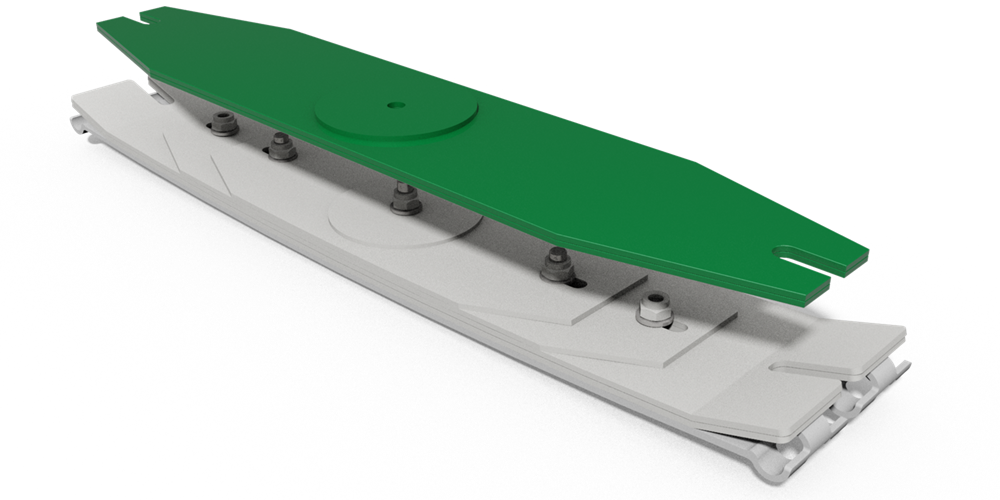

Our bodies work even at speeds of up to 10 km/h, while with a plow set the optimal speed is 8 - 9 km/h. The work of each body gives the effect of even furrow edges with full inversion of each furrow, even with a large amount of organic residues. Much of this is due to the cylindrical-screw type depot, which puts little resistance additionally significantly reducing fuel consumption. The bodies are also great at crushing larger lumps of soil. As standard, shear bars mounted on each body work on soils with a large amount of crop residues, without reducing the clearance between the bodies, as in the case of using skimmers, and thus do not cause the risk of clogging the machine. You will certainly appreciate the simple screw regulation of the depot and the angle of attack of the whole body, especially when you set low fuel consumption as a determinant of effective work.

A strong rubber wheel mounted behind the last working section of the plow stabilizes the machine's operation and reliably maintains the set working depth limited on the adjustment scale by means of a smooth adjustment crank.

(NOT AVAILABLE WITH OPEN-WORK MOULDBOARDS)

(2017 version)