Our machines

| Model | Working width (m) | Weight (kg)* | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| PO2 | 0.70-1.00 | 1000 | 70-100 | 2 | 0.56-0.8 | 30 |

| PO3 | 1.05 - 1.50 | 1250 | 80 - 115 | 3 | 0.8 - 1.3 | 30 |

| PO4 | 1.40 - 2.00 | 1500 | 115 - 140 | 4 lub 3+1 | 1.0 - 1.7 | 30 |

| PO5 | 1.75 - 2.50 | 1740 | 130 - 180 | 5 lub 4+1 | 1.2 - 2.0 | 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

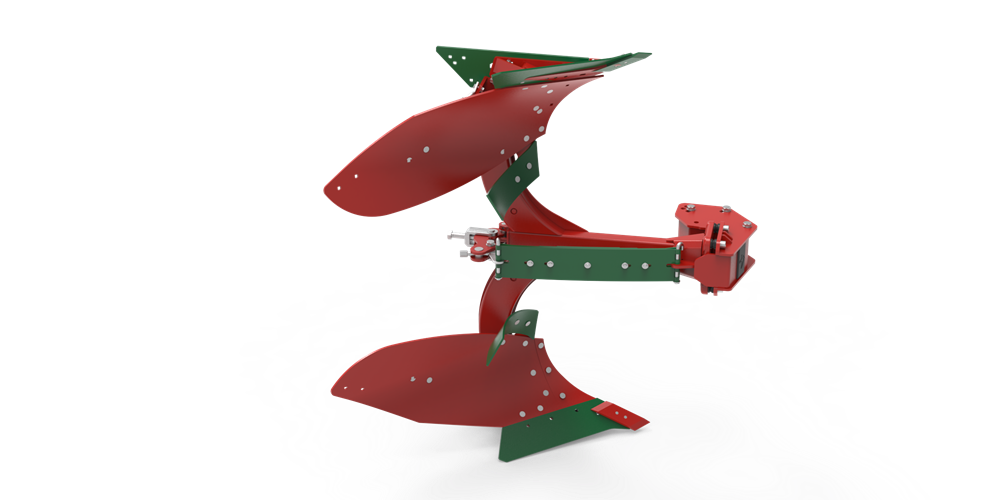

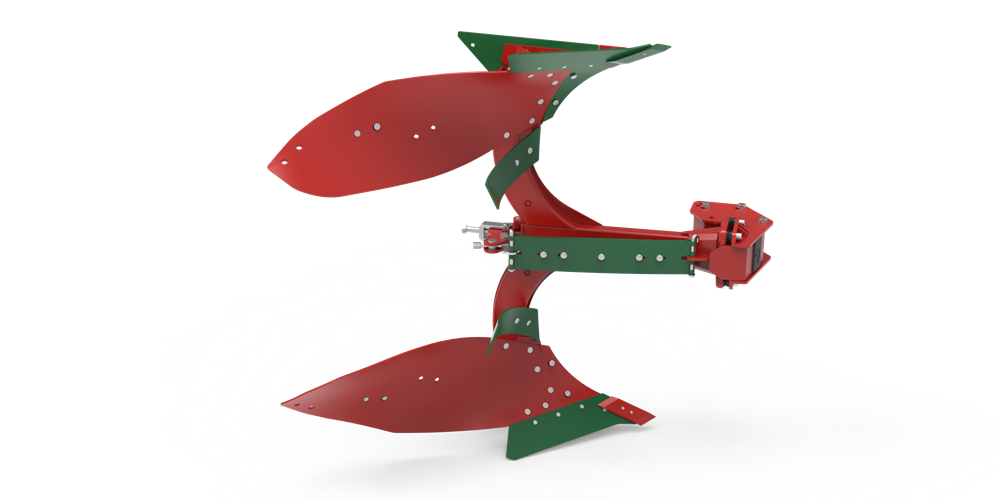

Reliability and user-friendly simplicity encapsulated in a robust construction. Our plows combine these features and will undoubtedly meet your requirements. A suitable ground clearance of 76 cm and a body spacing of 100 cm ensure coverage even of substantial amounts of crop residues and weeds. The use of high-grade steel has allowed us to achieve a very durable construction with the lowest total machine weight in its class. The frame (140 x 140 mm profile) made from thermally enhanced steel provides assurance that the plow will handle even in challenging conditions. Our experiences, satisfied customer feedback, and continuous testing allow us to create new solutions, resulting in the next generation of reversible plows.

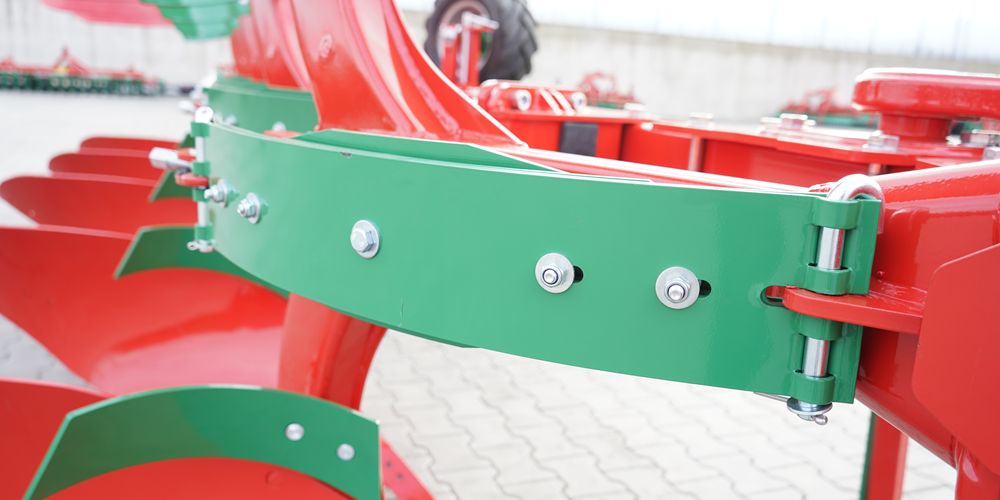

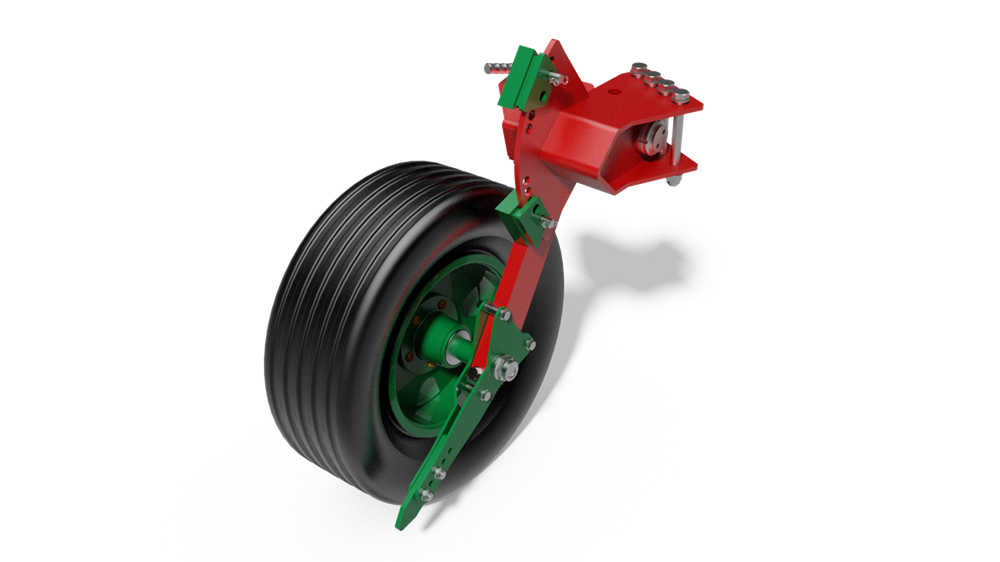

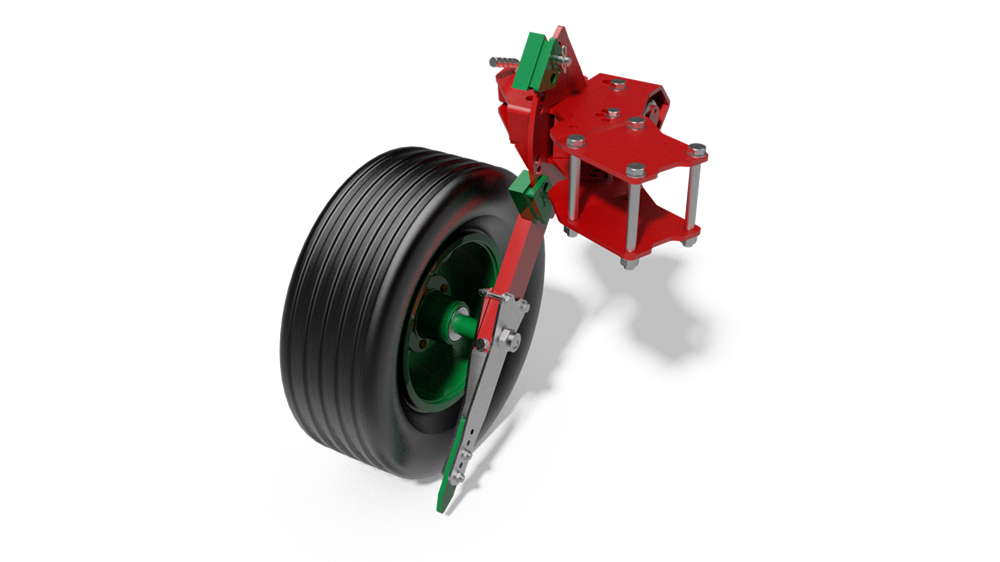

Spring-based body protection works best in soils where the plow would be exposed to frequent shearing of safety bolts. Each body independently reacts to obstacles, and the spring allows minimizing the forces generated during collisions and the rapid return of the body to the precisely set working position. The unique technology of the pivot points at the connection of each body with the pocket allows stress-free plowing in almost any conditions. Each spring forms a system of feathers made of spring steel responsible for maintaining the position of the bodies and their deflection in case of force applied to the blade exceeding that set on the adjustment screws. Efficient and straightforward. The load that must act on the body for the spring protection to engage is 520 kg (5 feathers) and 720 kg (7 feathers).

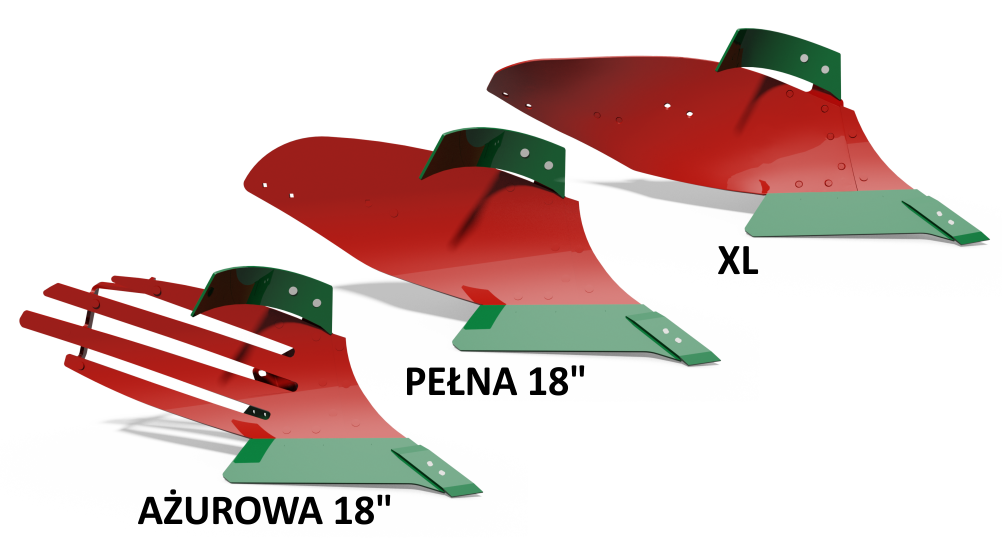

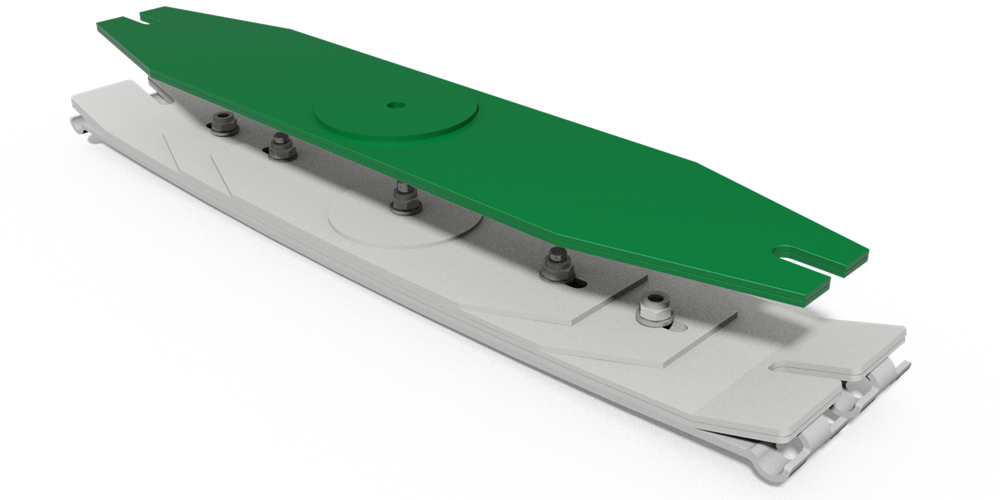

Our bodies perform well even at speeds of up to 10 km/h. The work of each body results in well-leveled furrow edges with the complete inversion of each share, even with a large amount of organic residues. Much of this is thanks to the cylindrical-screw mould boards, which offer minimal resistance and significantly contribute to reducing fuel consumption. The bodies also excel at breaking up larger soil clods. The standard installation of cutting strips on each body works well on soils with a high amount of crop residues, without reducing the clearance between the bodies, as is the case with the use of pre-plows, thereby eliminating the risk of machine clogging. You will surely appreciate the simple screw adjustment of the mould board and the approach angle of the entire body, especially if you consider low fuel consumption as a key indicator of effective work.

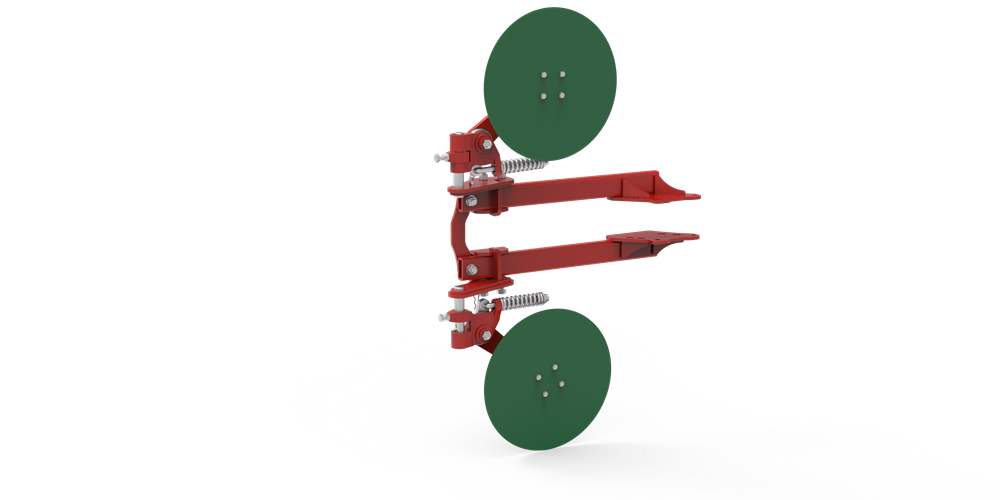

Serrated discs with a diameter of 500 mm, both for models with screw and spring protection, significantly enhance the visual effect of plow operation. By cutting the furrow from the soil, the cutting discs ensure the most accurate inversion of the share, leaving a clean furrow with smooth walls. Additionally, the action of the cutting discs increases the coverage effect of crop residues. Like any working element, the cutting discs are protected against damage in heavy soil conditions. In this case, a spring with adjustable pressure serves as the safety mechanism. Meanwhile, toothed adjustment blocks assist in achieving the optimal working position for the cutting disc.

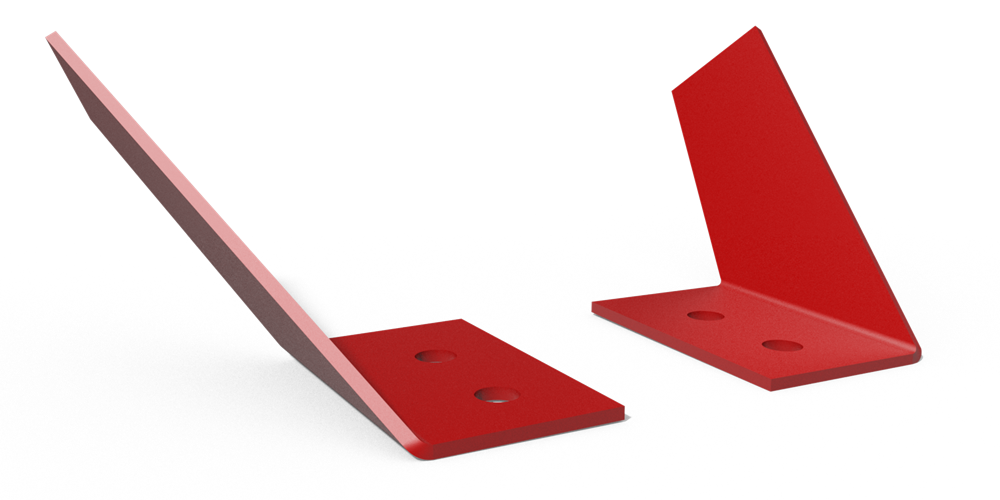

During plowing of long-fallow fields, meadows, or pastures, extension strips mounted on the mould boards prove to be extremely useful.

Increasingly chosen by farmers as a more cost-effective alternative to cutting discs.

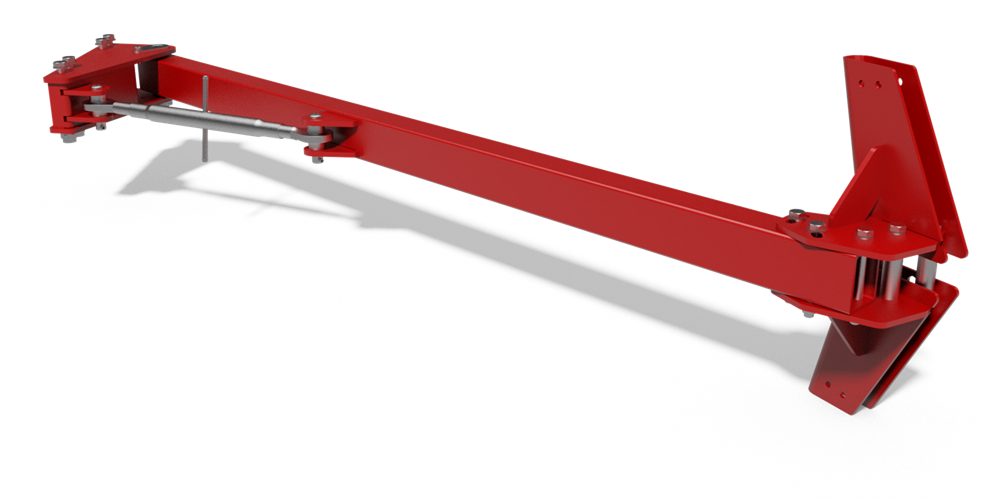

In one pass, we perform plowing and secondary soil compaction by breaking up large clods, leaving the field well-prepared for subsequent treatments. The shaft arm is adjustable, and the coupling/uncoupling of the shaft occurs automatically.

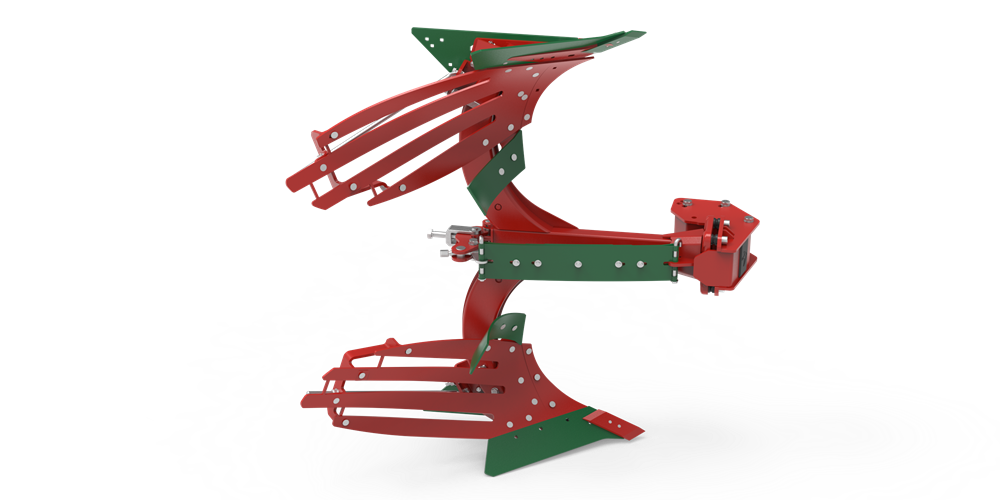

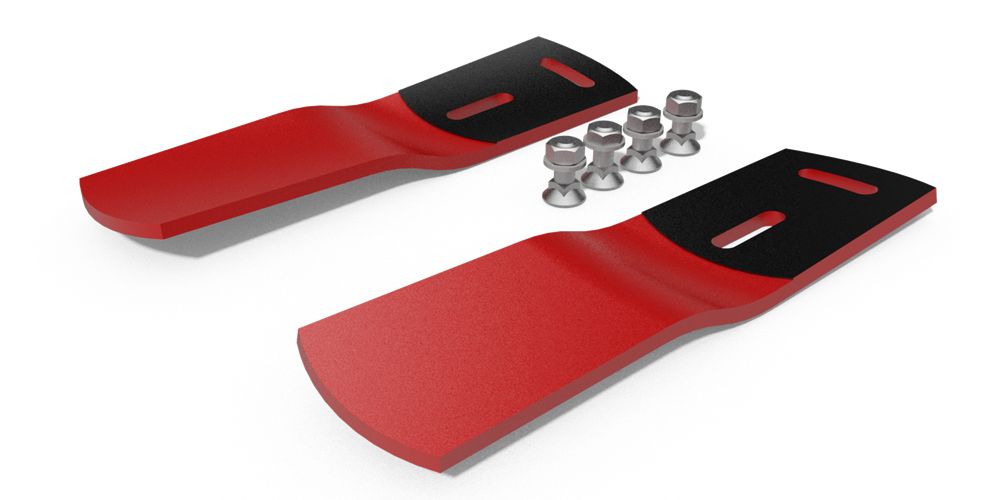

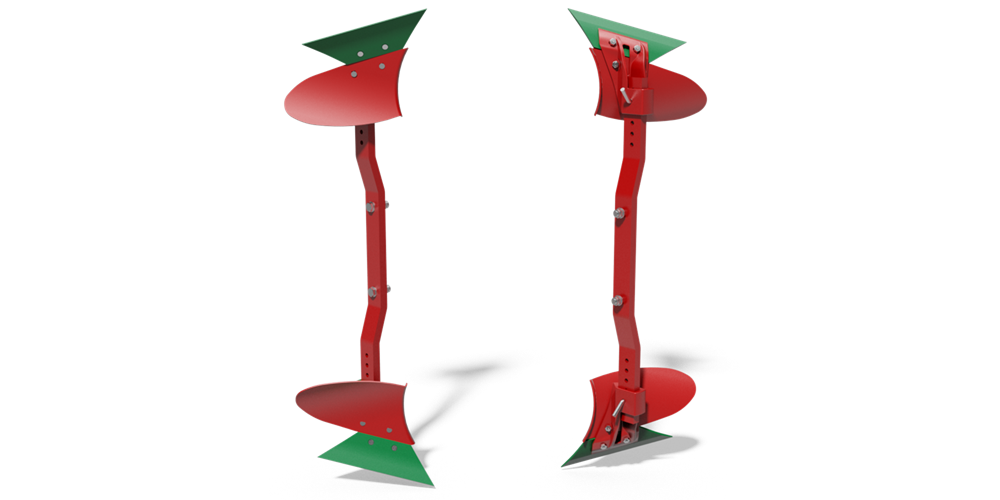

o achieve the most comprehensive mixing with the soil and cover crop residues effectively, the plow can be equipped with a set of front furrow attachments. The optimal position of their work is adjustable through a multi-stage incremental adjustment. Changing the position of the front furrow attachments is easily done using an adjusting screw, which is locked to secure the position of the attachment. Each front furrow attachment has a universal and popular overload protection in the form of a breakable screw. Each individual handle of the front furrow attachment is mounted to the pocket of the main body, ensuring that the working geometry of the front furrow attachment is identical to the characteristics of the body on which it is mounted. Front furrow attachments work particularly well in corn stubble fields. When the user determines that satisfactory results are achieved using cutting strips, they can quickly remove the front furrow attachments and return to the previous configuration.