Our machines

| Model | Width (m) | Weight (kg)* Share Bolt protection | Weight (kg)* Spring protection | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|---|

| GIANT 7 | 2.45 - 3.5 | 4500 | 4700 | 210 | 7 | 1.96 - 2.8 | 30 |

| GIANT 8 | 2.80 - 4.0 | 4700 | 5000 | 240 | 8 | 2.24 - 3.2 | 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

The future of your crop production direction is safe with robust and efficient machines, and inexpensive. The GIANT plow series gives you the certainty of a quick return on costs, allowing you to focus on crops. The rotary plow concept is part of the idea of efficient and fast plowing without unnecessary downtime. While developing the concept of rotary plows, AGRO-MASZ designers focused on the use of the latest technical solutions available, such as a thermally improved frame and construction based on bolted joints to extend the life of the machine. It guarantees reliability for a long time.

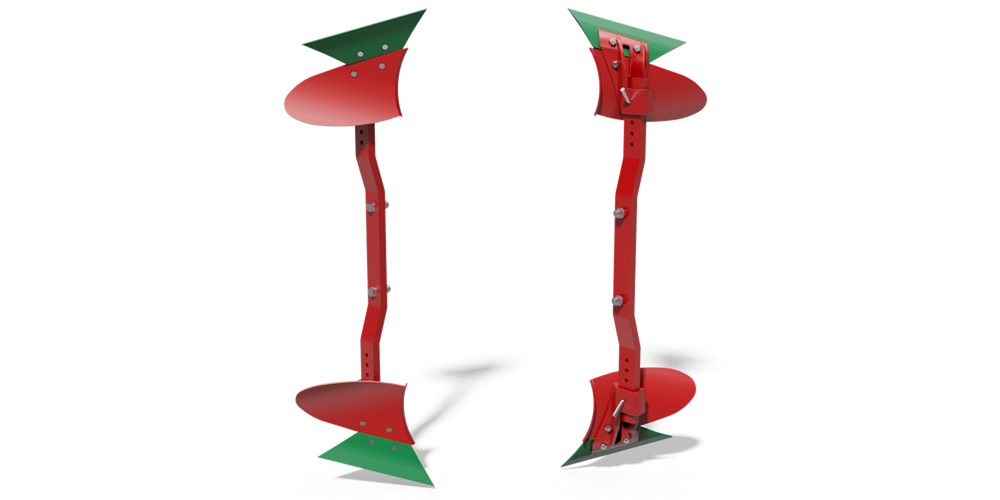

Spring protection of the body works best on soils where the plow would be exposed to frequent shearing of the fuse bolts. Each body independently reacts to obstacles, and the spring allows to minimize the forces arising during a collision and to quickly return the body to the precisely set working position. The unique technology of making articulated points located on the connection of each body with the pocket allows you to lead plowing in almost any conditions without stress. Each spring forms a system of leaves made of spring steel responsible for maintaining the position of the bodies and their deflection in the event of a force acting on the blade which exceeds that set on the adjustment bolts. Efficient and simple.

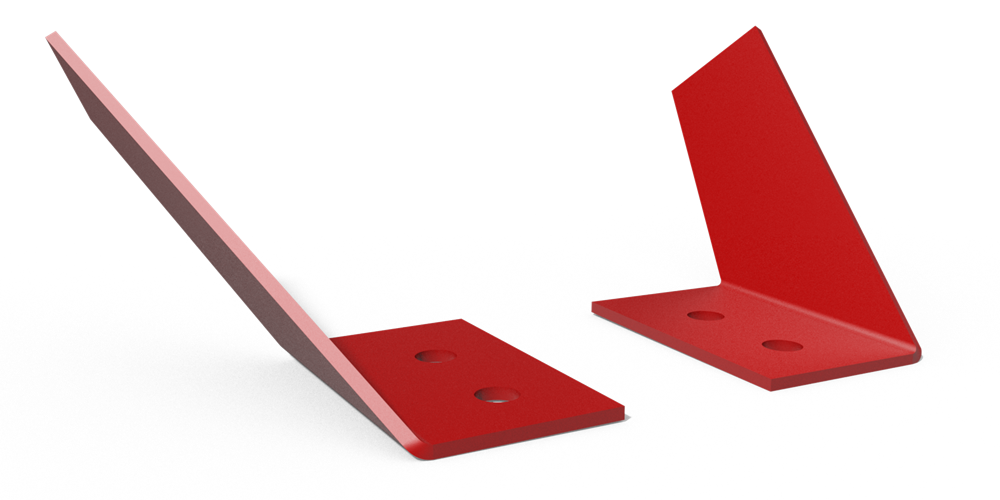

For each type of soil, in conditions of non-stony or slightly stony fields, the most effective and cheap solution is to protect the bodies against damage with breakable bolts. The screw blocking the body position is cut when the plow body hits a sufficiently large obstacle. Passing the bolt through two pocket plates eliminates the undesirable effect of deformation of the holes in which the bolt is located and does not leave the possibility of the bolt jamming in the structural hole of the body. Replacing the screw is therefore easy.

Reliability and efficiency - these are not all the advantages of our plows. The use of high-strength steel gave us the opportunity to create an extremely durable and light plow. The frame (profile 180 x 180 mm) made of steel with improved parameters, thermally improved, ensures that the plow will cope even in difficult conditions. Our experience, opinions of satisfied customers and continuous tests allow us to create new solutions, which results in the next generation of rotary plows.

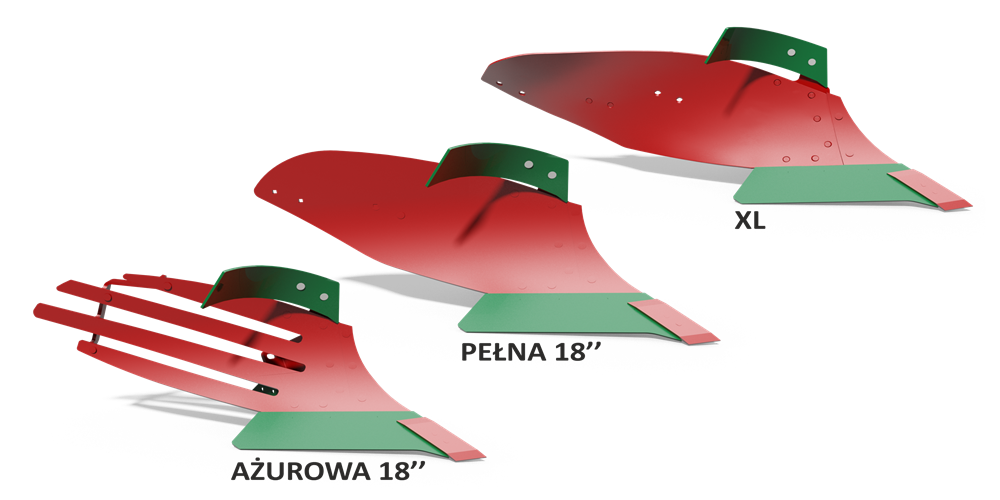

Our bodies work even at speeds of up to 10 km/h. The work of each body gives the effect of even furrow edges with full inversion of each furrow, even with a large amount of organic residues. Much of this is due to the cylindrical-screw type depot, which puts little resistance additionally significantly reducing fuel consumption. The bodies are also great at crushing larger lumps of soil. As standard, shear bars mounted on each body work on soils with a large amount of crop residues, without reducing the clearance between the bodies, as in the case of using skimmers, and thus do not cause the risk of clogging the machine. You will appreciate the simple screw regulation of the footboard and the angle of attack of the whole body, especially when you set low fuel consumption as a determinant of effective work.

When plowing fallow land, meadows or pastures, extension slats mounted on mouldboards are extremely useful.

More and more often chosen by farmers as a cheaper replacement for the disc cut.

To achieve the fullest effect of mixing with the soil and covering crop residues, the plow can be equipped with a set of skimmers. Determining the optimal position of their work is possible thanks to multi-step adjustment. The position of the skimmers is easily changed by means of an adjustment screw, which blocks the position of the skimmer. Each skimmer has universal and popular overload protection in the form of a break screw. Each individual handle of the skimmer is mounted to the main body pocket, which guarantees that the working geometry of the skimmer will be identical to the work characteristics of the body on which it is mounted. Skimmers are particularly well suited to working on corn stubble. When the user decides that the use of shear bars gives a satisfying effect, he can quickly dismantle the skimmers and return to the previous configuration.