Our machines

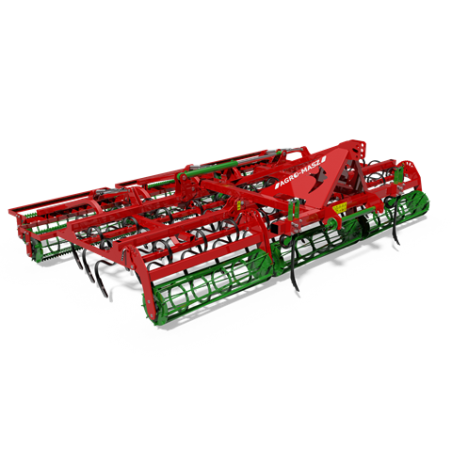

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of tines (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| AU36 | 3.6 | 1080 | 85 - 95 | 36 | 2.0 - 4.0 | 4 - 13 |

| AU42 | 4.2 | 1180 | 95 - 115 | 42 | 2.9 - 5.0 | 4 - 13 |

| AU50 | 5.0 | 1560 | 110 - 140 | 50 | 3.5 - 6.1 | 4 - 13 |

| AU56 | 5.6 | 1660 | 120 - 160 | 56 | 4.1 - 7.2 | 4 - 13 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

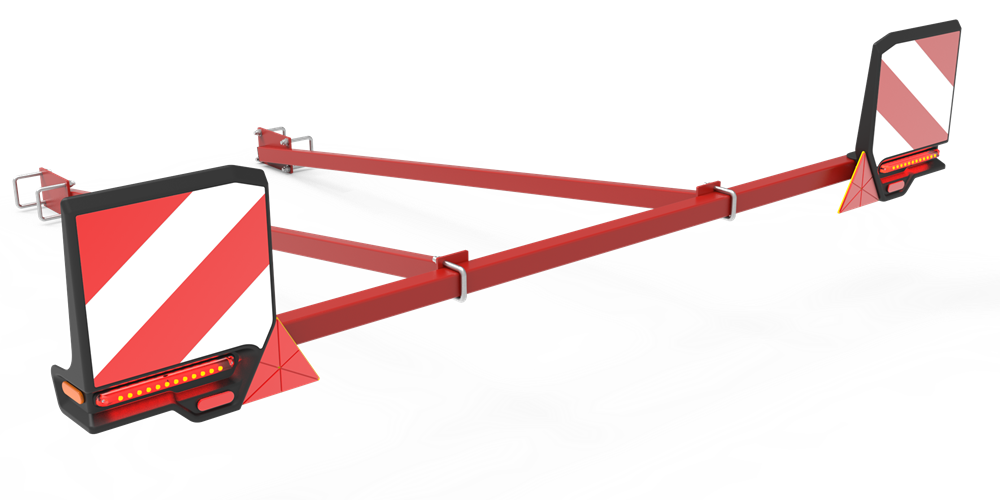

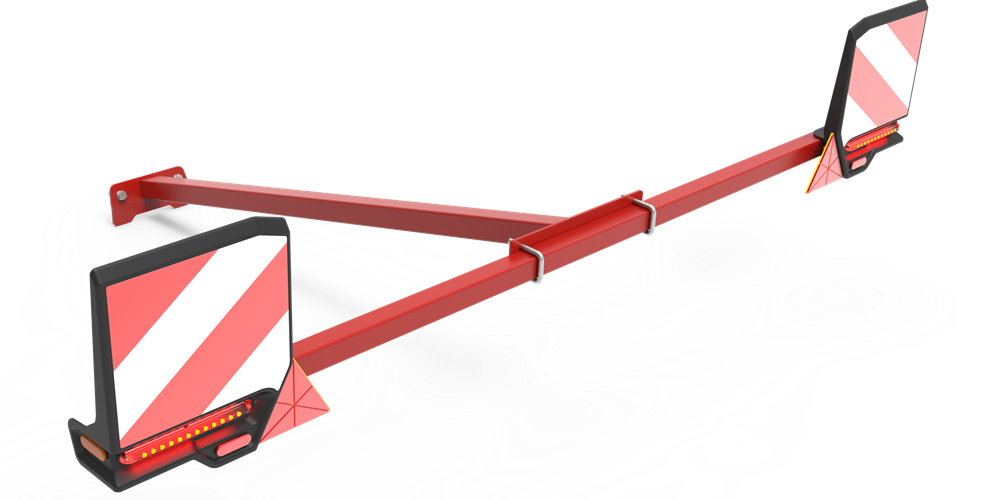

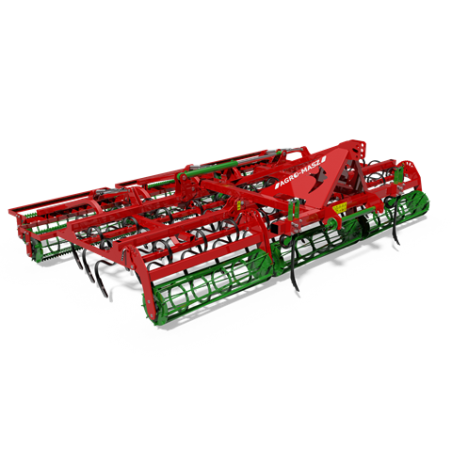

The design of mounted tilling sets has been designed so that the machine obtains the maximum working width. Depending on the working width, it is transported in three or four sections. The system is based on double-acting cylinders and is safely operated from the operator's position.

The arrangement of string rollers with a diameter of 320 mm is the section responsible for the initial leveling of transverse soil unevenness. The last working section of the machine is also string rollers, however, arranged in a tandem arrangement. You will no doubt get the optimal alignment!

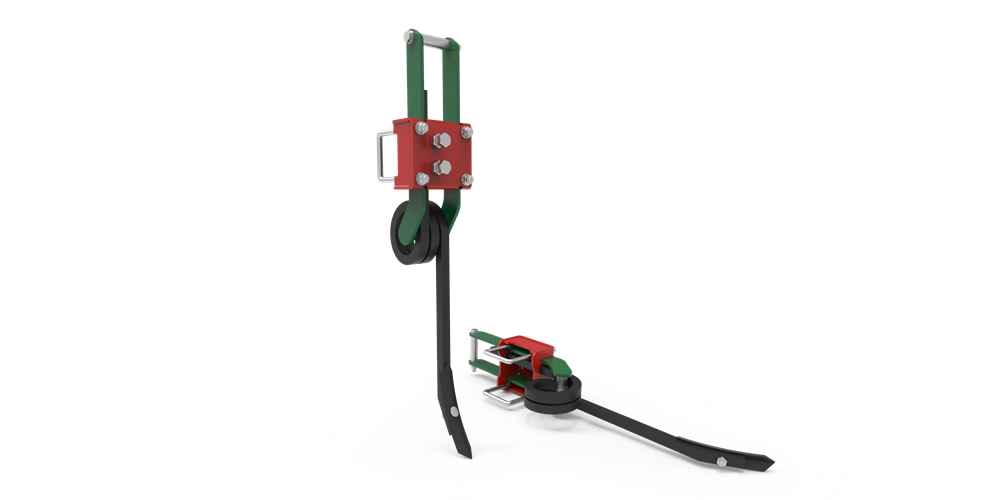

he spring steel teeth arranged in four sections ensure the effect of maximum crumbling of lumps of soil. Ended are coulters with a double-sided blade, which automatically extends their service life. Thanks to the right combination of distances between successive beams and ground clearance, they provide excellent work results in both light and heavy soil conditions.

Setting the optimum geometry of the working position of individual components for given field conditions does not require much effort. We set the depth of work of the front shafts relative to the claw section on the scale with pins, and the position of the rear shafts with turnbuckles.