Our machines

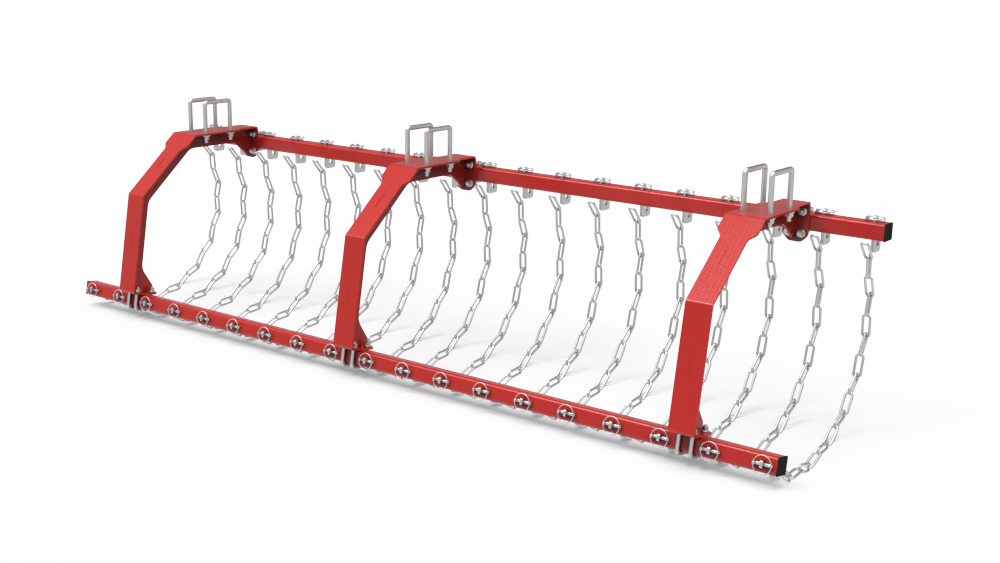

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of tines (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| AP21 | 2.1 | 1050 | 80 - 100 | 5 | 1.47 - 2.10 | 4 - 13 |

| AP26 | 2.6 | 1200 | 100 - 120 | 6 | 1.80 - 2.60 | 4 - 13 |

| AP30 | 3.0 | 1400 | 110 - 140 | 7 | 2.10 - 3.00 | 4 - 13 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

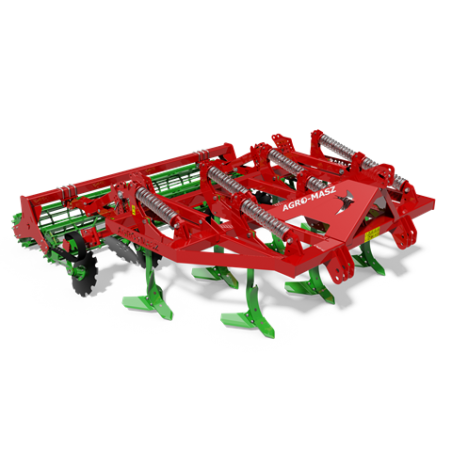

Properly shortened design, high throughput, the possibility of deep and shallow stubble cultivation are strong arguments that will allow you to get great results. The machine is available in the most popular working widths.

Non-stop. These words include the whole philosophy based on the efficient protection of working elements combined with comfortable operation that does not require frequent operator intervention. For each type of soil, in conditions of non-stony or slightly stony fields, the most effective solution is the double spring system we use to protect each claw. In addition, when the spring's operating range is exceeded, the securing screw will be cut.

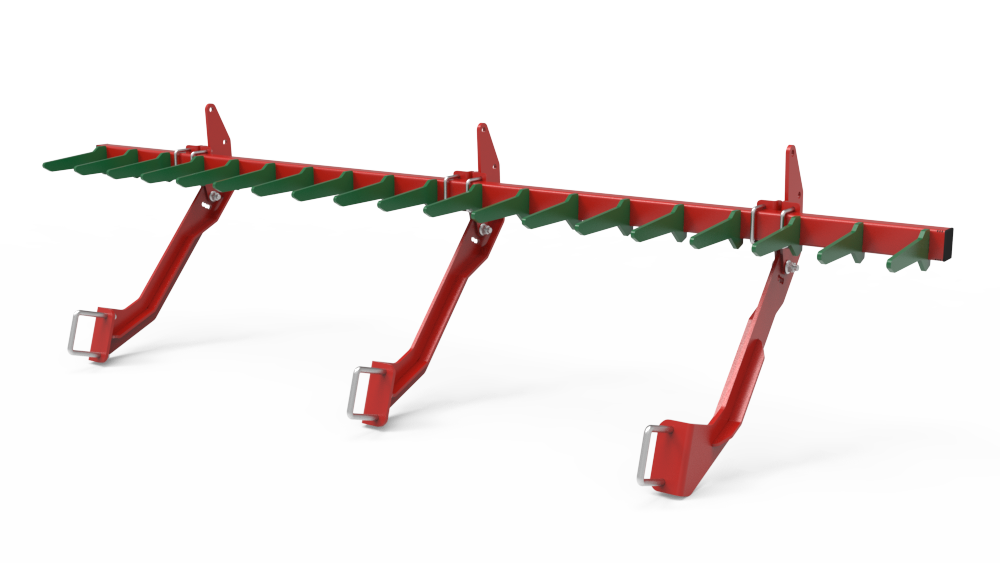

The combination of claws with double-sided blades and a small mouldboard arranged at the right angle to the ground in two rows will allow even and intensive mixing of crop residues without duplication of passages. Thanks to the right combination of distances between beams and ground clearance, they provide excellent results in both light and heavy soil conditions.

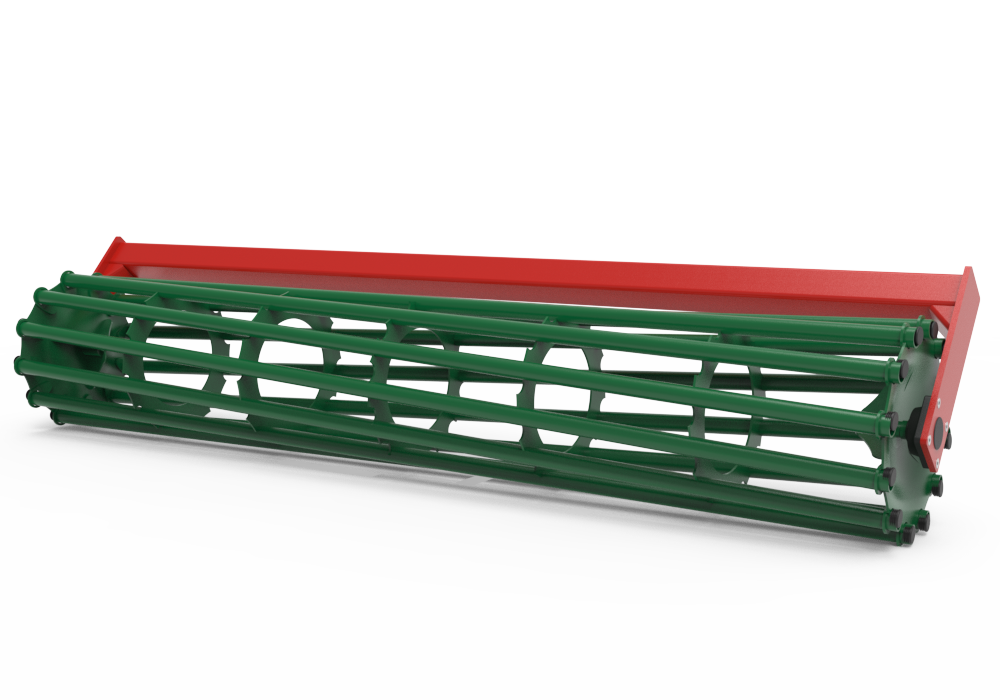

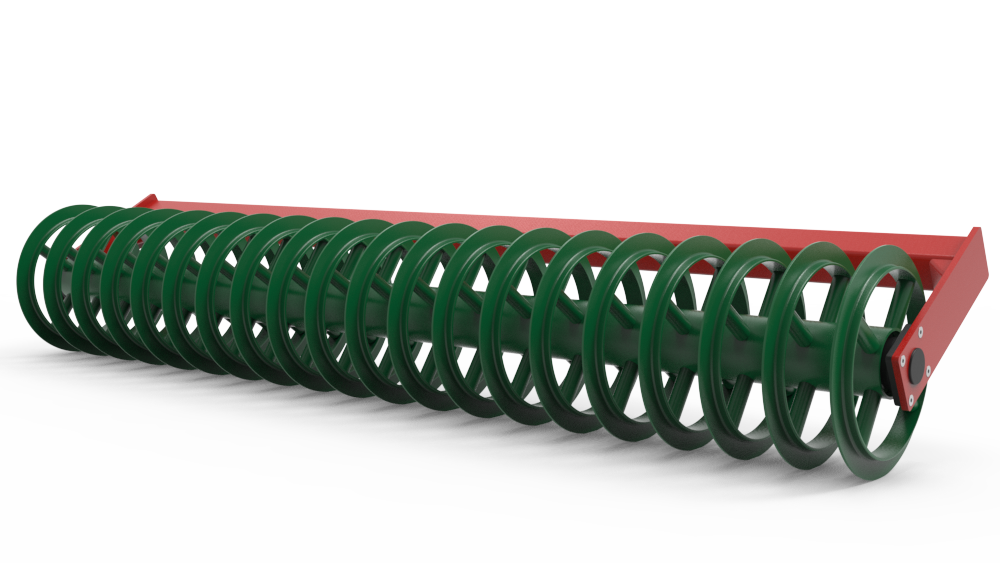

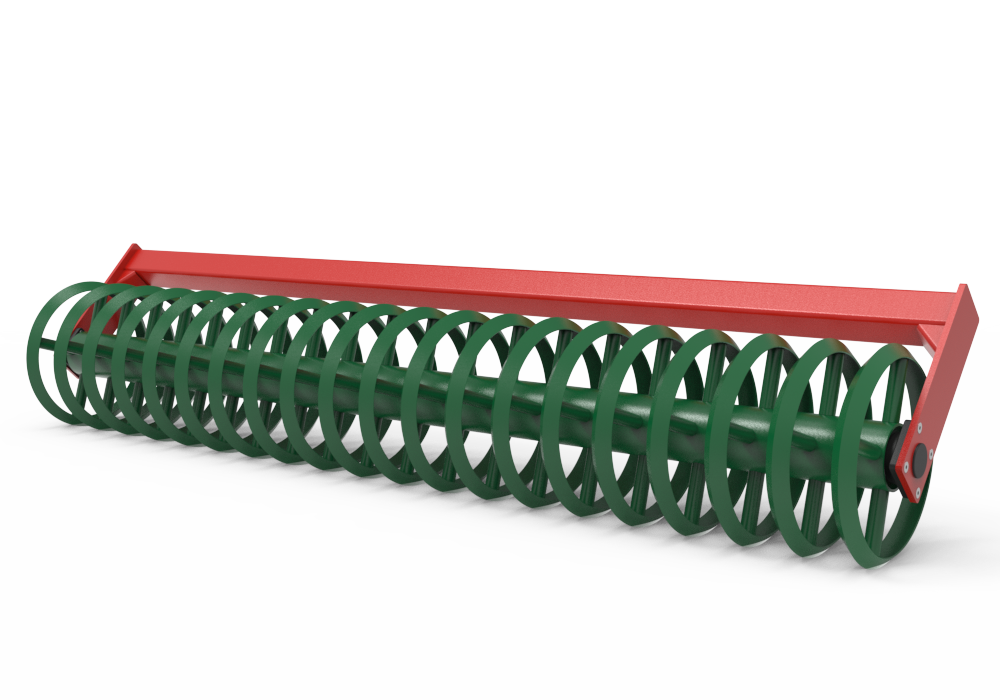

The better mixing and levelling effect of the cultivated strip is possible due to work of the toothed disks arranged against each other and fastened on the resilient arms.

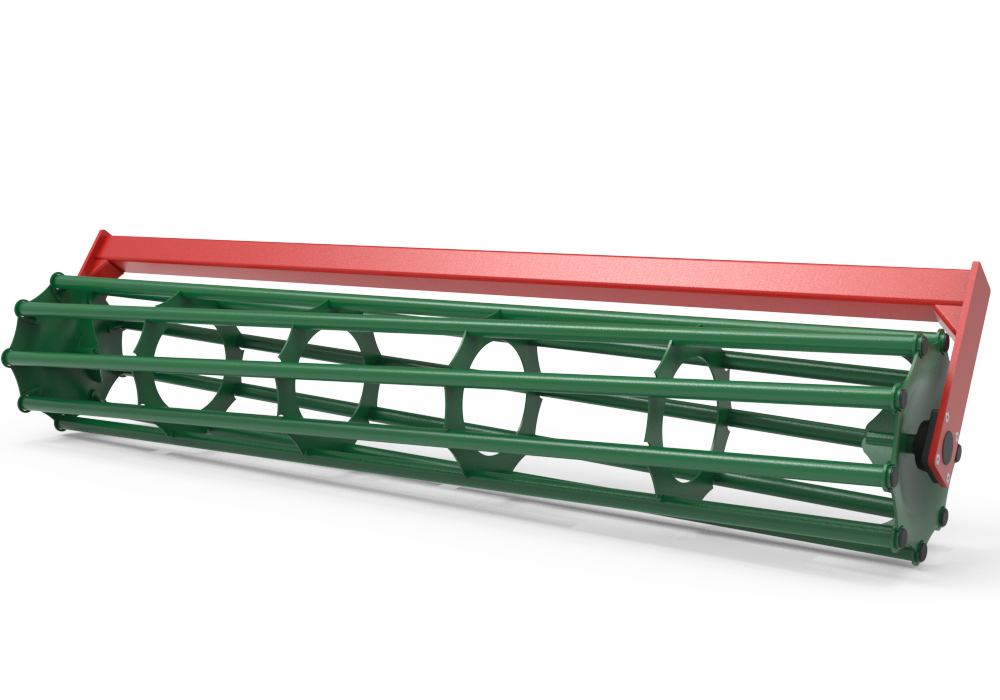

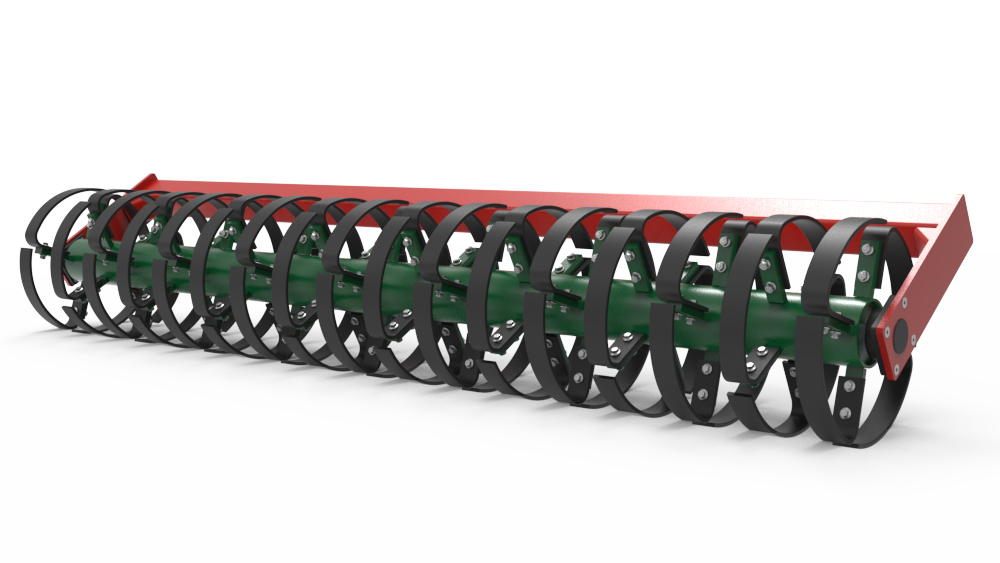

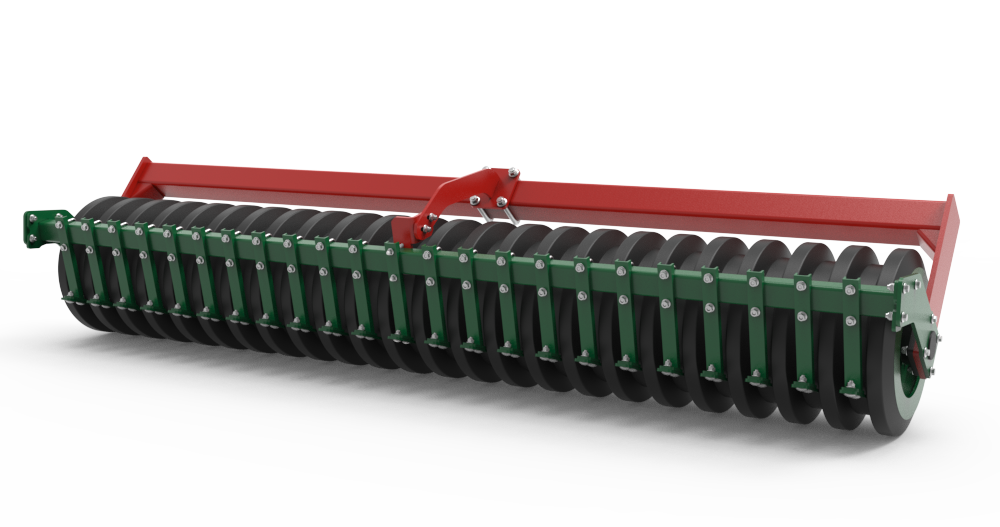

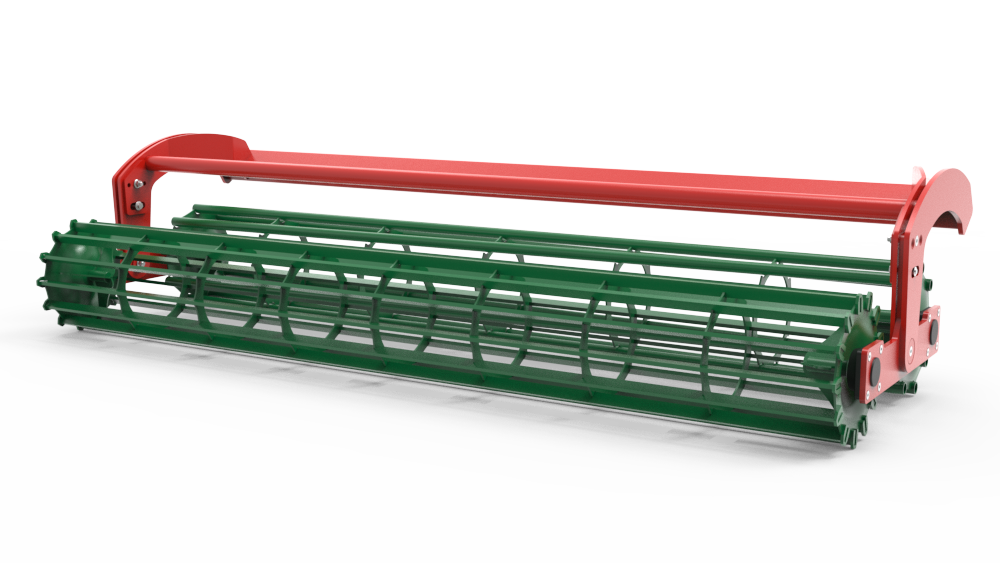

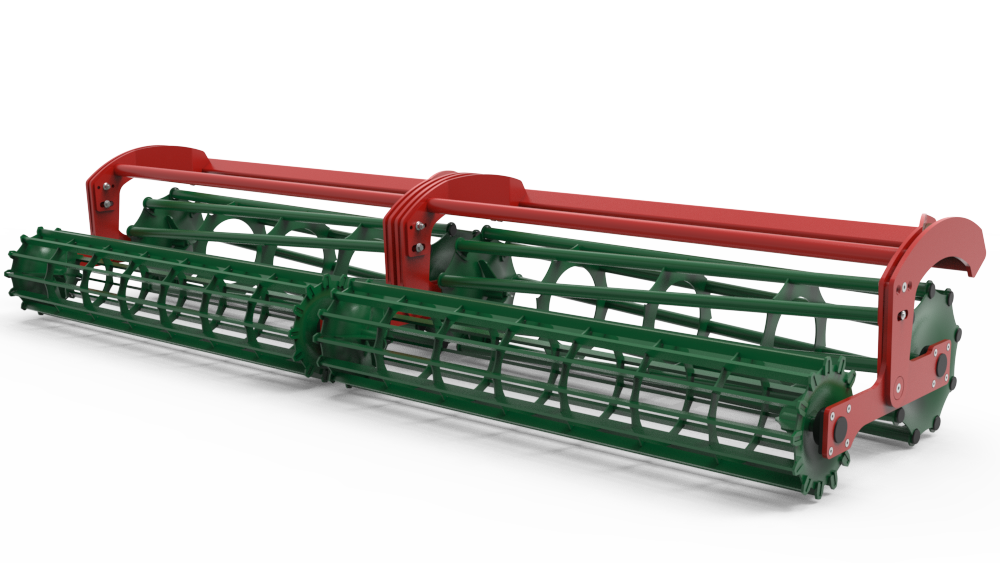

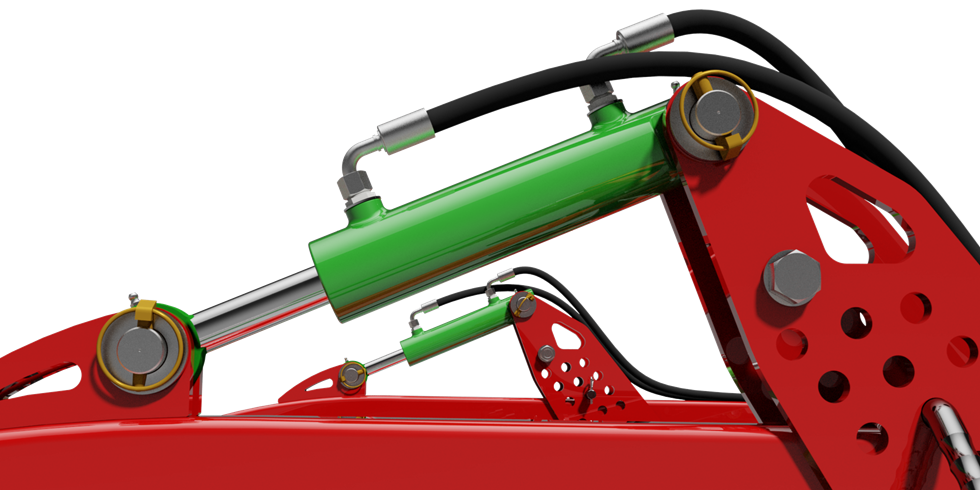

You will achieve the best leveling and compaction of soil by choosing a roller from a wide range of tillage rollers, suitable for different soil conditions. The set of shafts and their parameters located in the "SHAFTS" tab will be helpful in this. In addition to the properties resulting from its construction, the shaft performs another important function - the working depth on the shaft arms is adjusted at which the claws are to work. A simple arrangement of pins, whose position is changed in relation to the adjustment plates, allows to reduce claw penetration, taking into account specific soil conditions and the desired working speed.

The system of the locking pins of the arm position of the rear roller due to which the working depth of the machine is adjusted can be additionally equipped with the system of the supporting hydraulic cylinders at any time. In this version the working depth of the machine is adjusted in a comfortable manner by controlling the hydraulic system from the tractor cabin.