Our machines

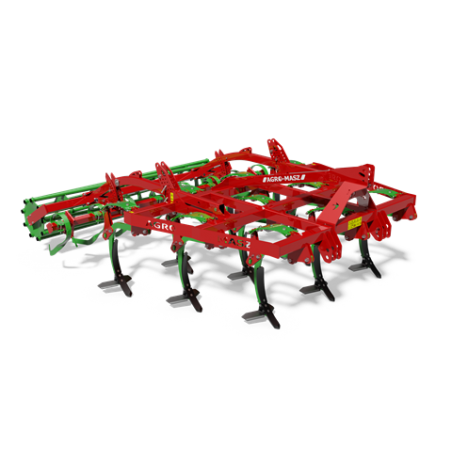

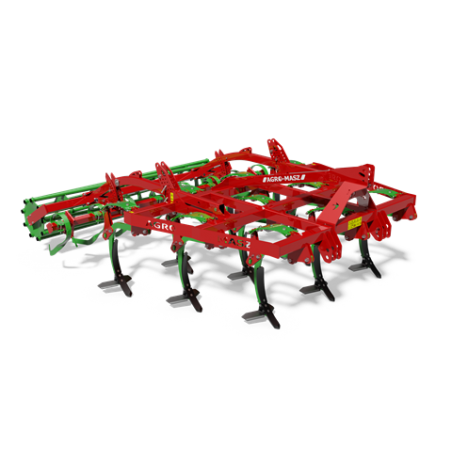

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of tines (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| AP30 | 3.0 | 1400 | 130 - 160 | 10 | 2.1 - 3.0 | 4 - 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

The properly shortened construction, high capacity, active protection, deep and shallow stubble field cultivation are the strong arguments that shall convince you to work with our aggregate.

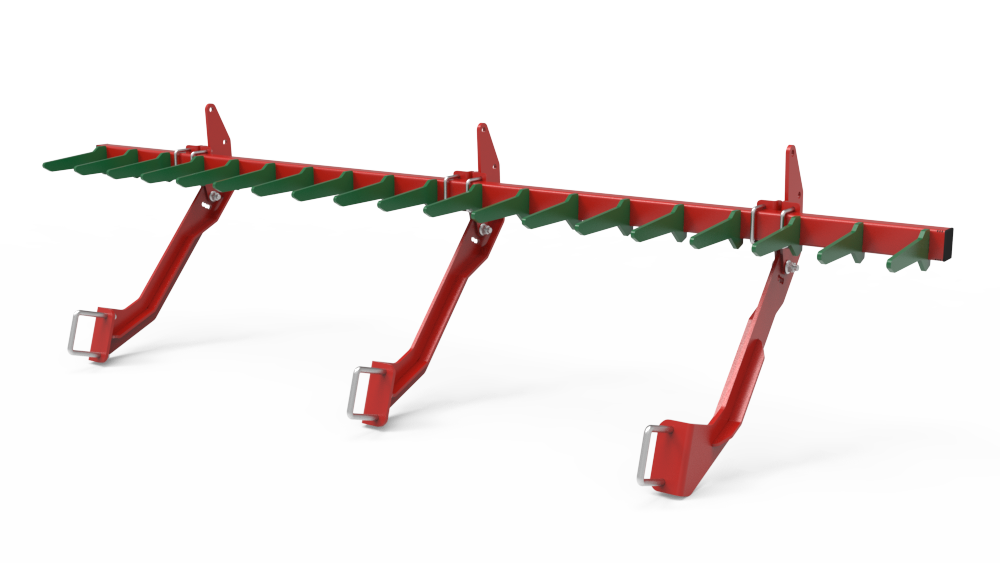

The combination of claws in three sections with double-sided blades and a long mouldboard tuned at the right angle to the ground in two rows will allow even and intensive mixing of crop residues. Having the opportunity to work also after removing the plowshares, we achieve greater working depths. Thanks to the right combination of distances between the beams and ground clearance you will get excellent results in all conditions.

Non-stop. These words include the whole philosophy based on the efficient protection of working elements combined with comfortable operation, which does not require frequent operator intervention. The spring protection system we use is the most effective solution for any soil type, in conditions of unstoned or slightly stony fields.

Each tooth reacts independently to obstacles, and the spring allows to minimize the forces arising during a collision and to immediately return the component to the precisely set working position. Each spring forms a system of leaves made of spring steel responsible for maintaining the position of the claw and its deflection in the event of a force acting on the coulter exceeding that determined on the adjustment bolts. Efficient and simple.

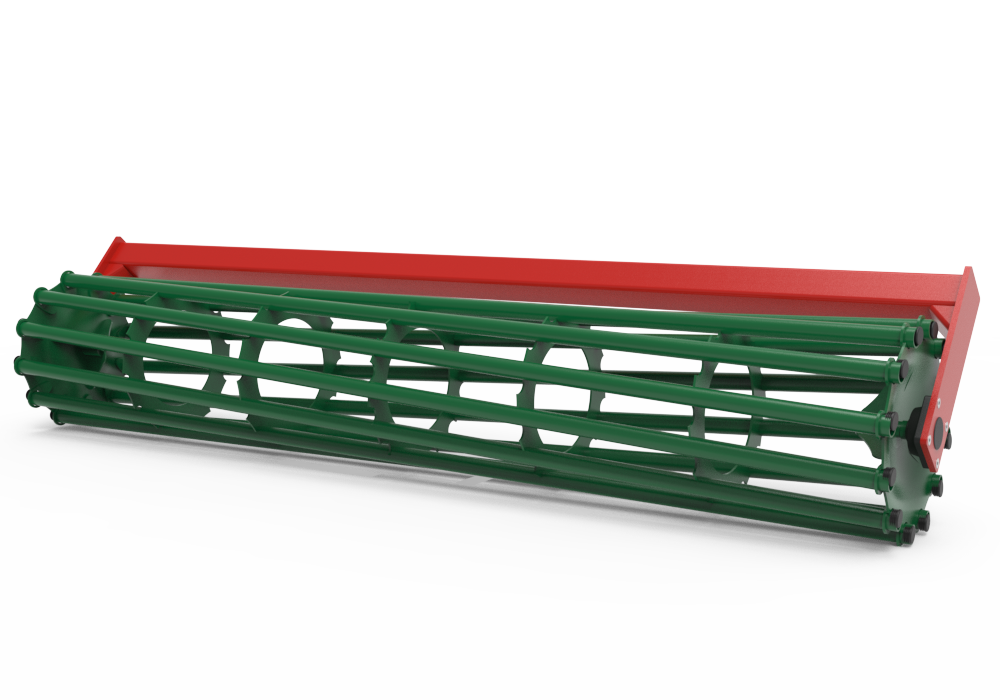

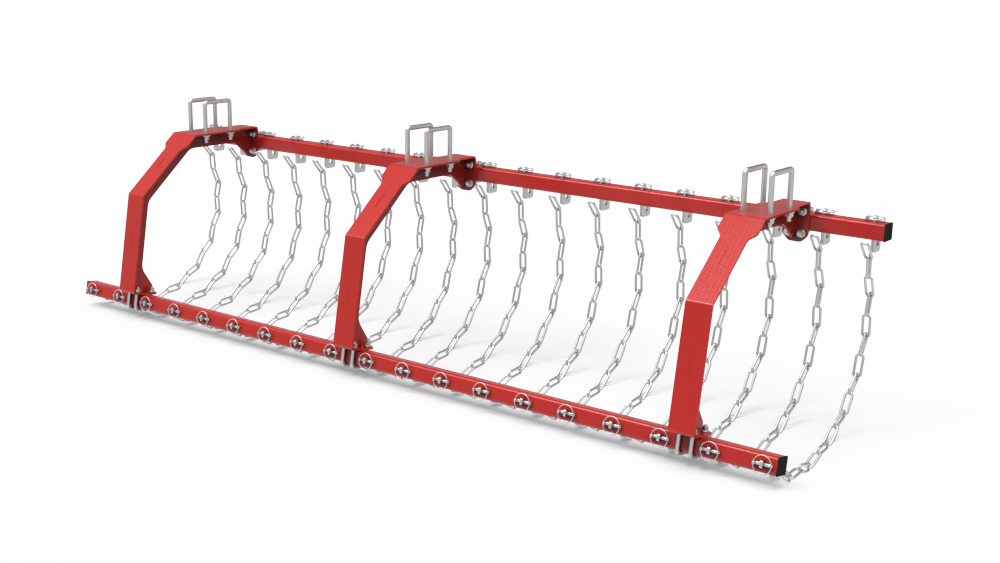

The effect of the better levelling of the cultivated strips is possible due to the work of the slats made of spring steel. Flexible and effective. In particular on the light soils with the small amount of agricultural crop residues.

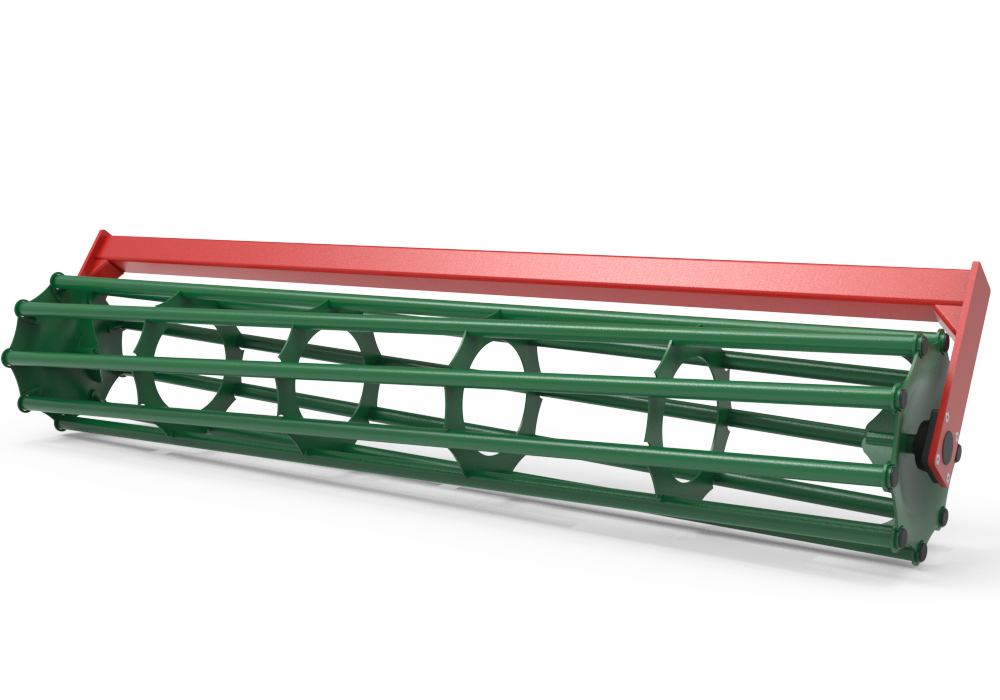

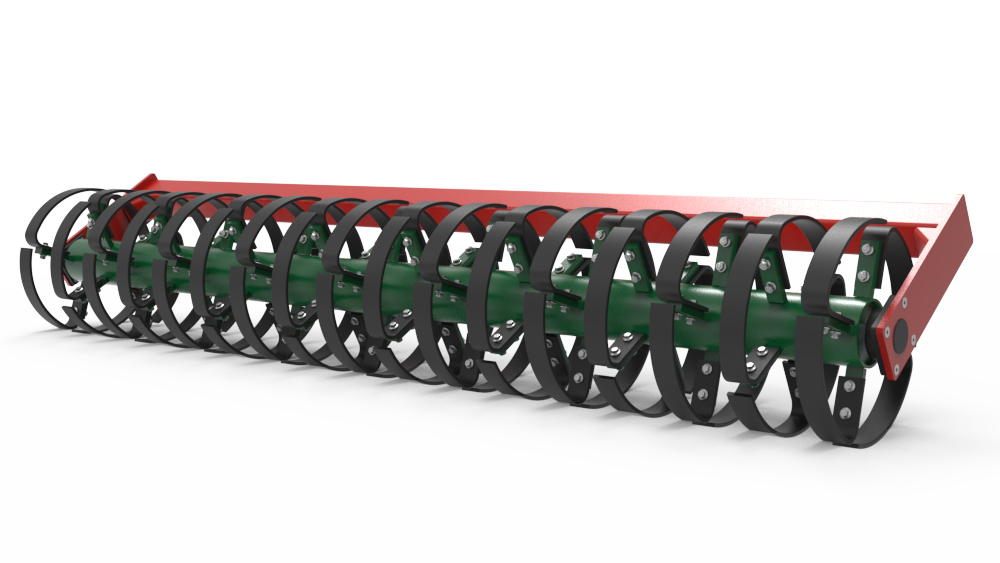

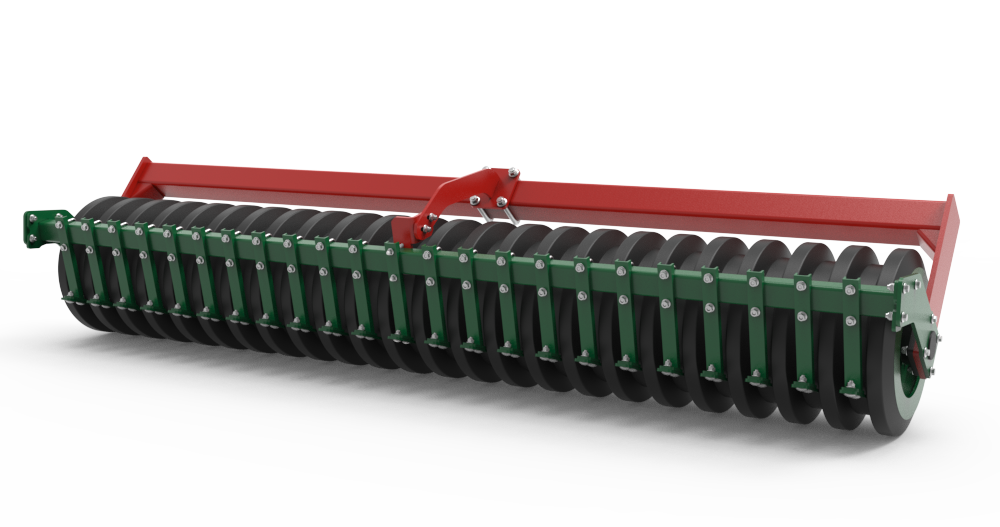

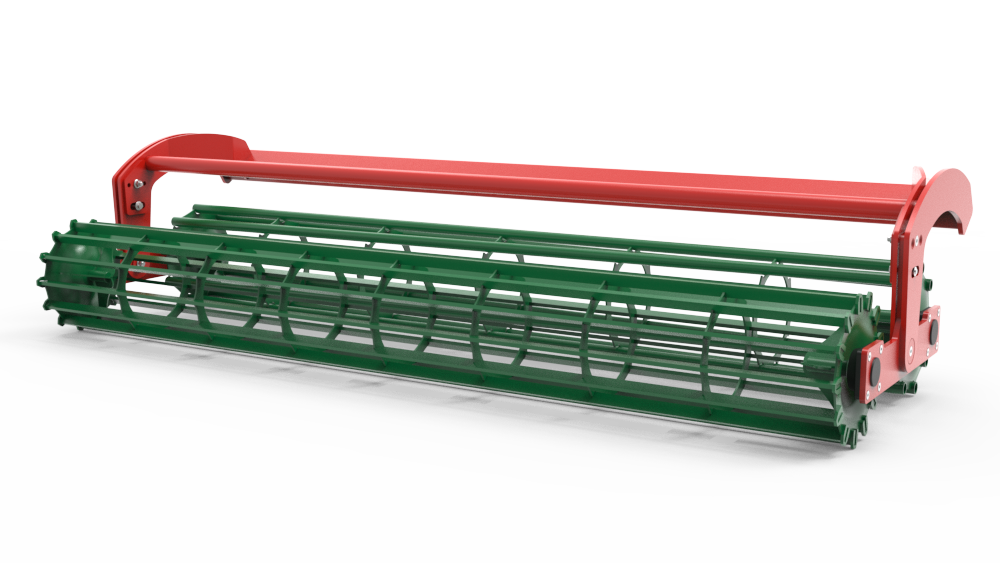

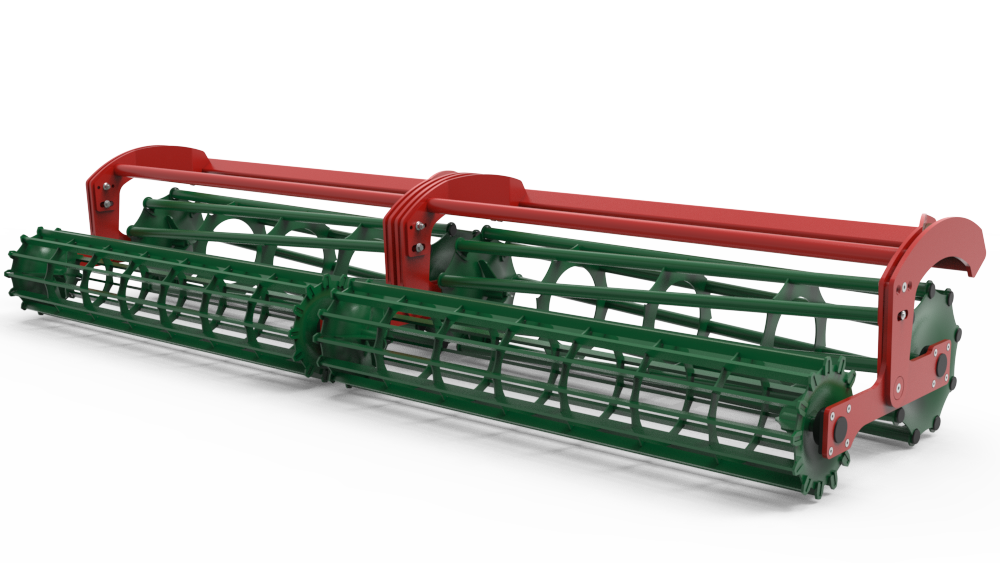

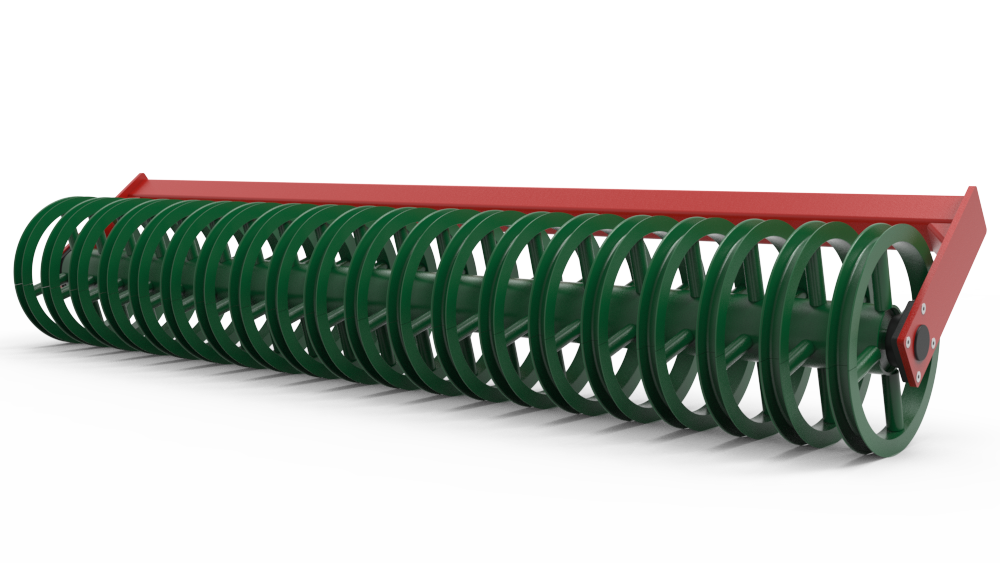

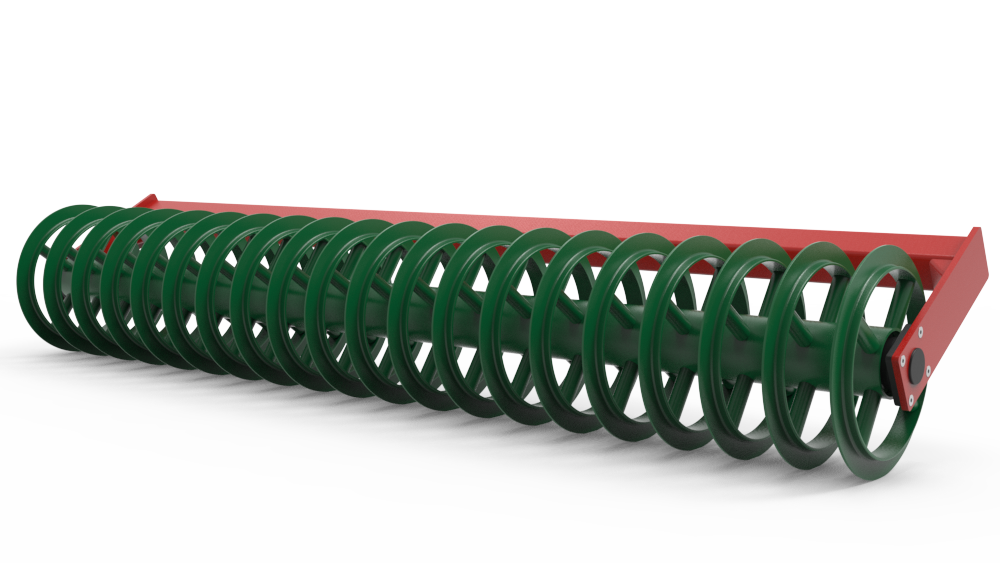

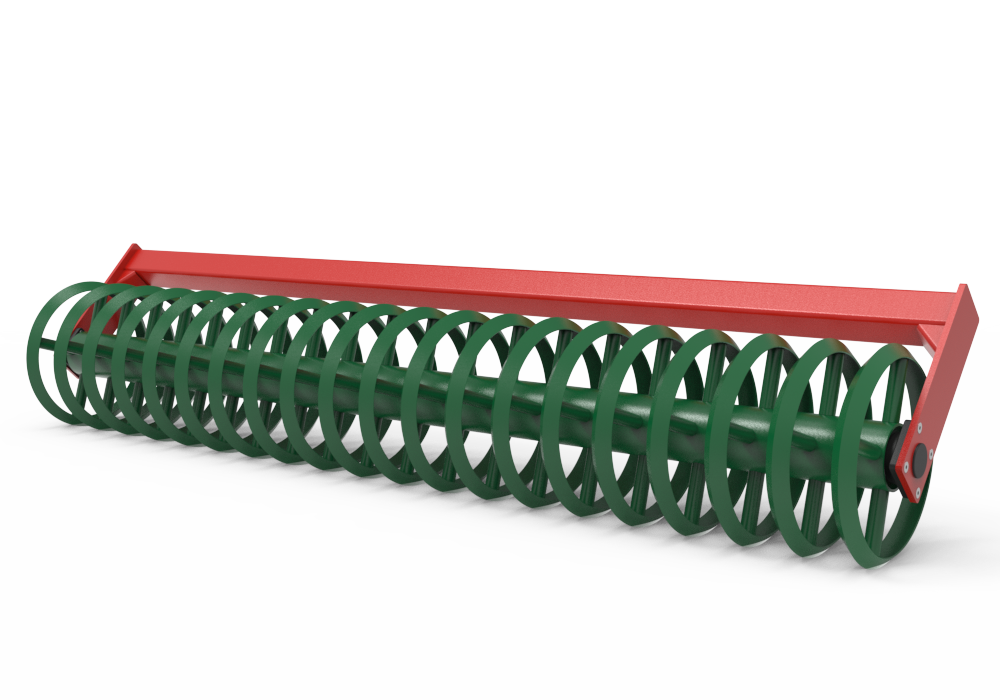

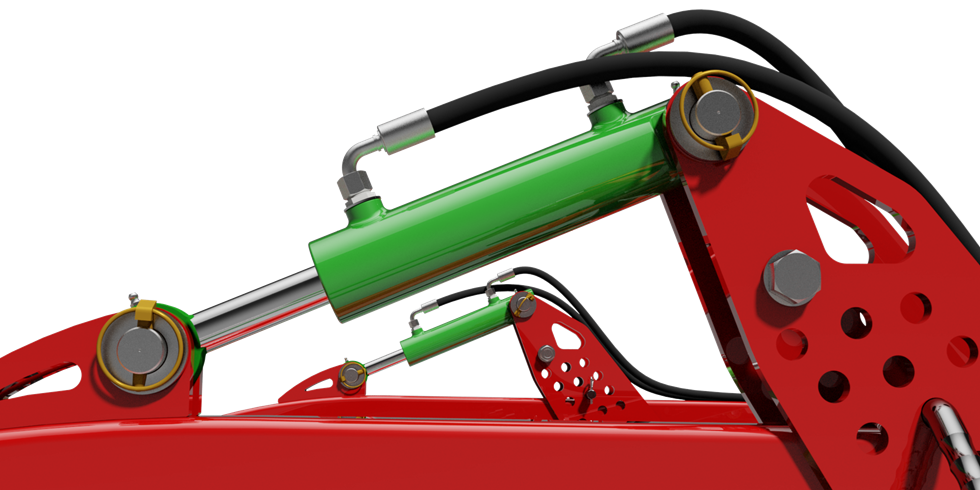

You will achieve the best leveling and compaction of soil by choosing a roller from a wide range of tillage rollers, suitable for different soil conditions. In addition to the properties resulting from its construction, the roller performs another important function - the working depth is adjusted on the shaft arms.

The system of the locking pins of the arm position of the rear roller due to which the working depth of the machine is adjusted can be additionally equipped with the system of the supporting hydraulic cylinders at any time. In this version the working depth of the machine is adjusted in a comfortable manner by controlling the hydraulic system from the tractor cabin.