Our machines

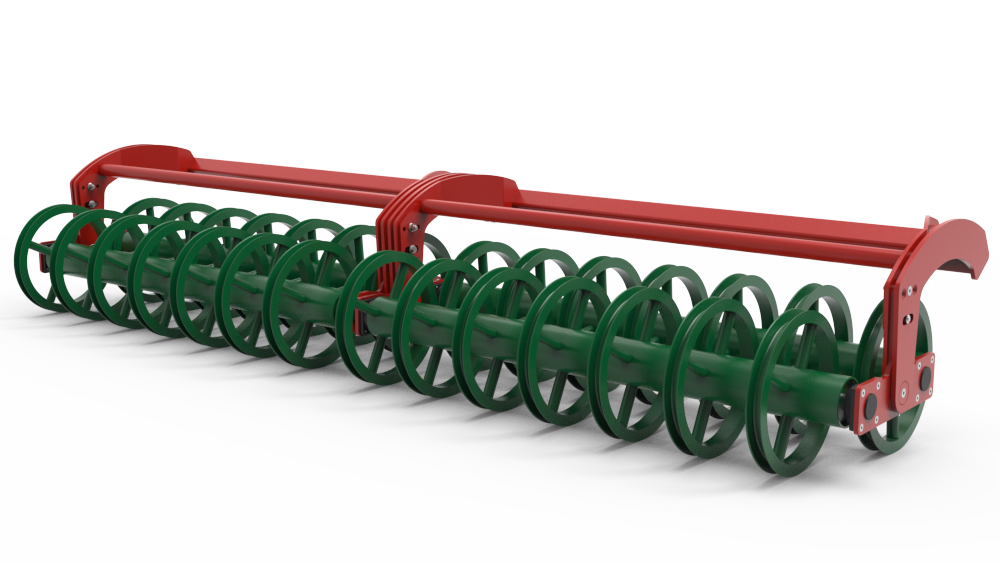

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of discs (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| BT40H | 4.0 | 2250 | 120 - 150 | 32 | 2.80 - 4.80 | 14 |

| BT50H | 5.0 | 2600 | 140 - 180 | 40 | 3.50 - 6.00 | 14 |

| BT60H | 6.0 | 3100 | 160 - 200 | 48 | 4.20 - 7.20 | 14 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

m.jpg)

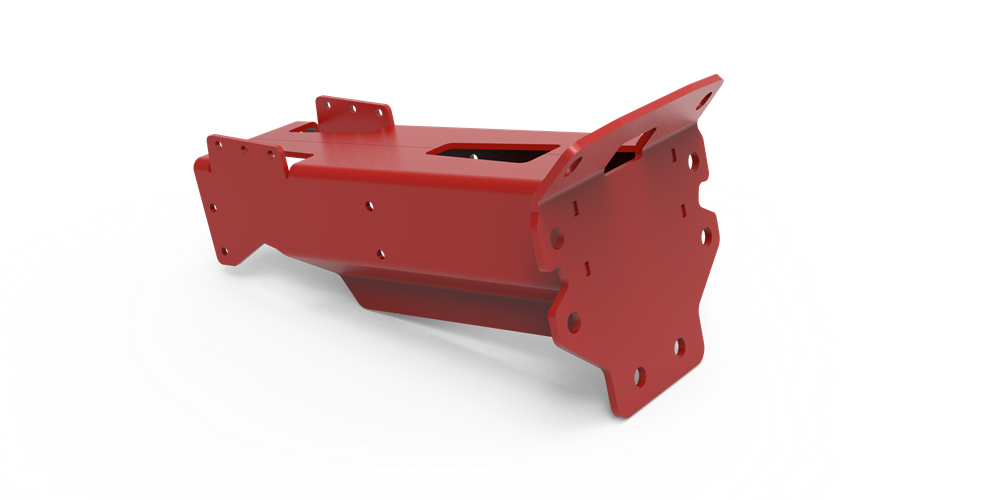

Disc harrows from the BTH series are machines designed for challenging tasks. With working widths reaching 6 meters and optionally available transport equipment, they excel in intensive and fast cultivation of stubble fields. They are efficient with simultaneous low fuel consumption. The disc harrows from the BT series handle stubble fields with a large amount of post-harvest residues excellently, as well as when restoring fallows for cultivation

m.jpg)

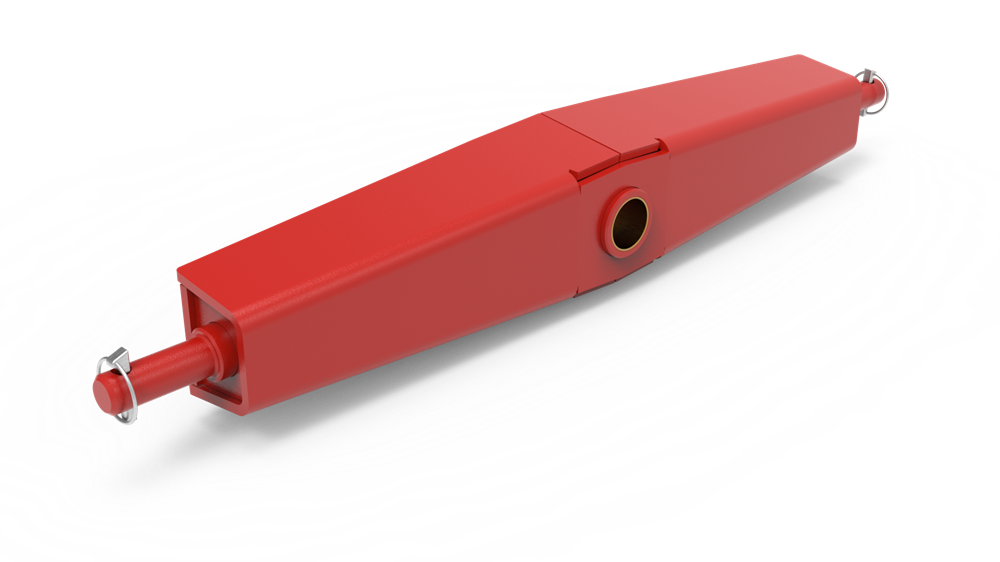

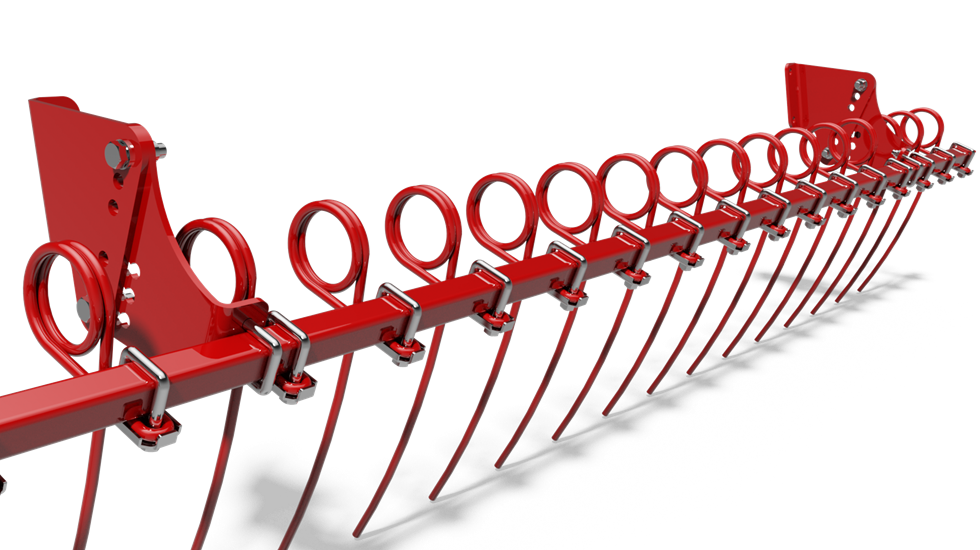

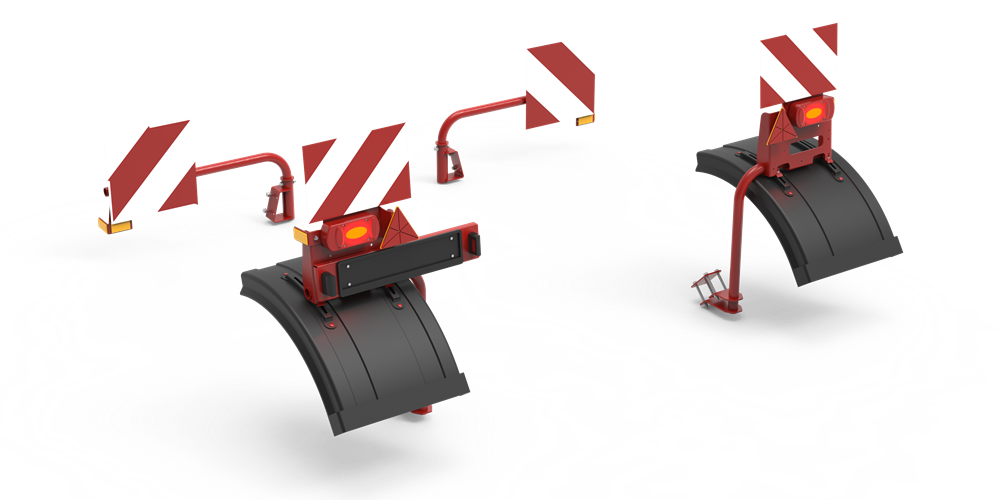

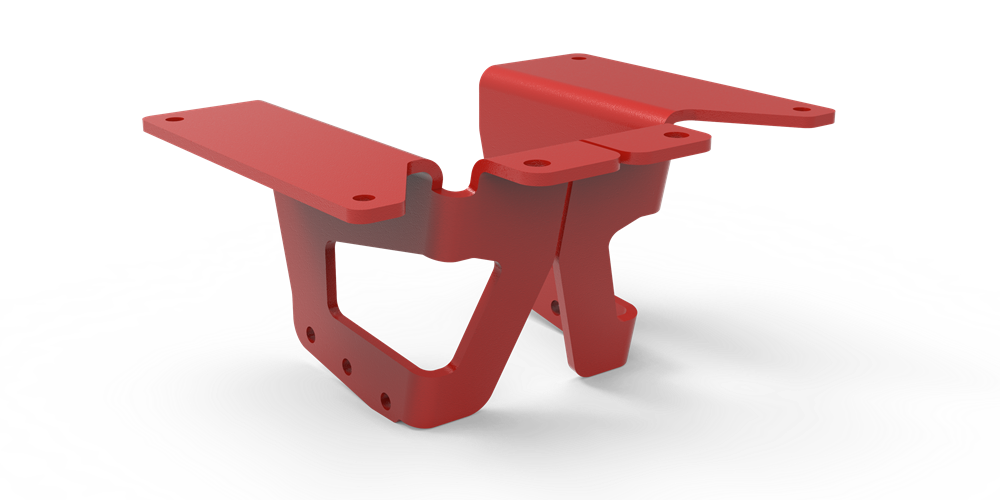

Each plate is mounted on an individual holder in a system of four rubber shock absorbers. They effectively protect the plates against damage. The shock absorbers also reduce vibrations transmitted to the machine. Work without worry, without breaks.

m.jpg)

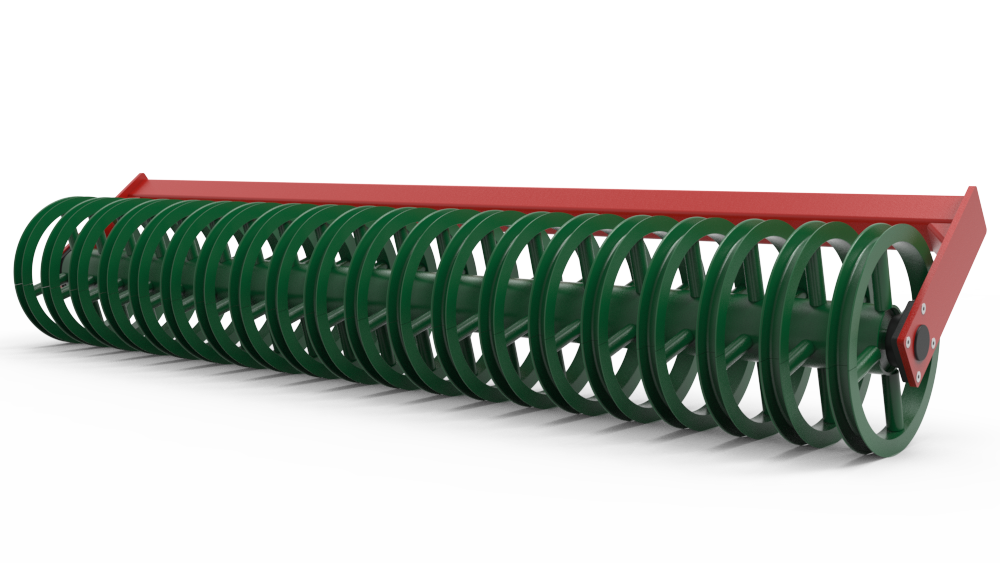

At optimally high working speeds, a properly chosen angle of attack and cutting angle of the discs enable the user to achieve maximum effectiveness in mixing crop residues with the soil while simultaneously reducing the spacing between disc rows to 85 cm or 100 cm. Two rows of discs with diameters of 560 mm or 510 mm are an additional advantage, providing precise and efficient soil processing, allowing for uniform and deep cutting of crop residues. This solution enhances the machine's work efficiency, making the hydraulically foldable disc harrow an indispensable tool in soil preparation for cultivation. It's not the machine that determines the possibilities of work; it's you who sets the limits!

m.jpg)

Does the daily maintenance of your old machine demand too much time and attention? It's time to forget about frequent bearing lubrication. Our disc harrows come standard with maintenance-free hubs, housing bearings identical to those used in the automotive industry. The entire system is sealed with cassette seals, proven to be highly effective in demanding field conditions.

m.jpg)

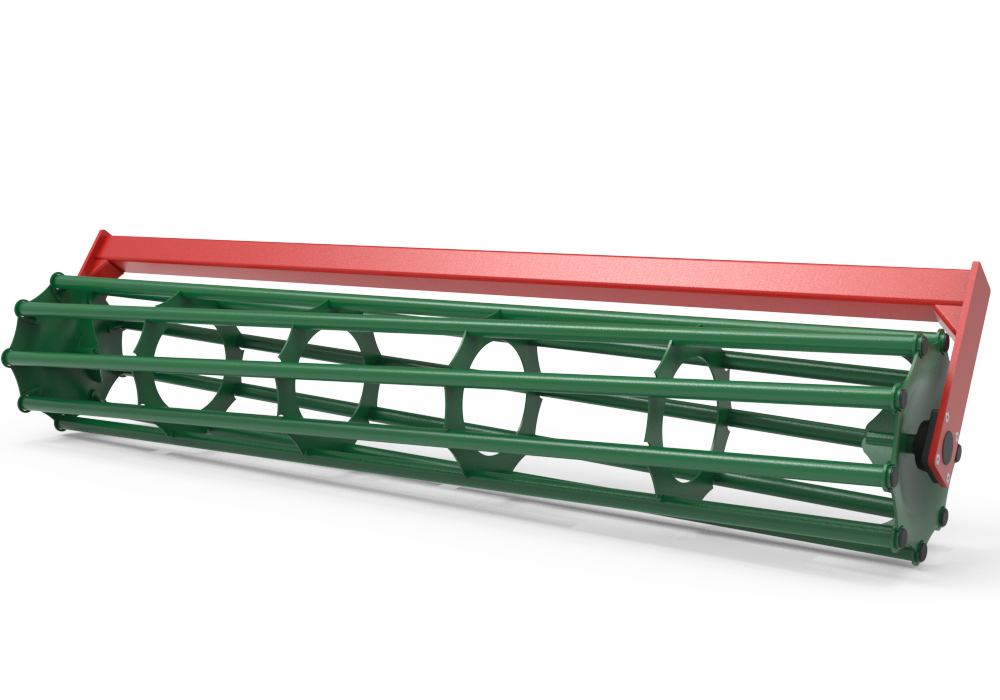

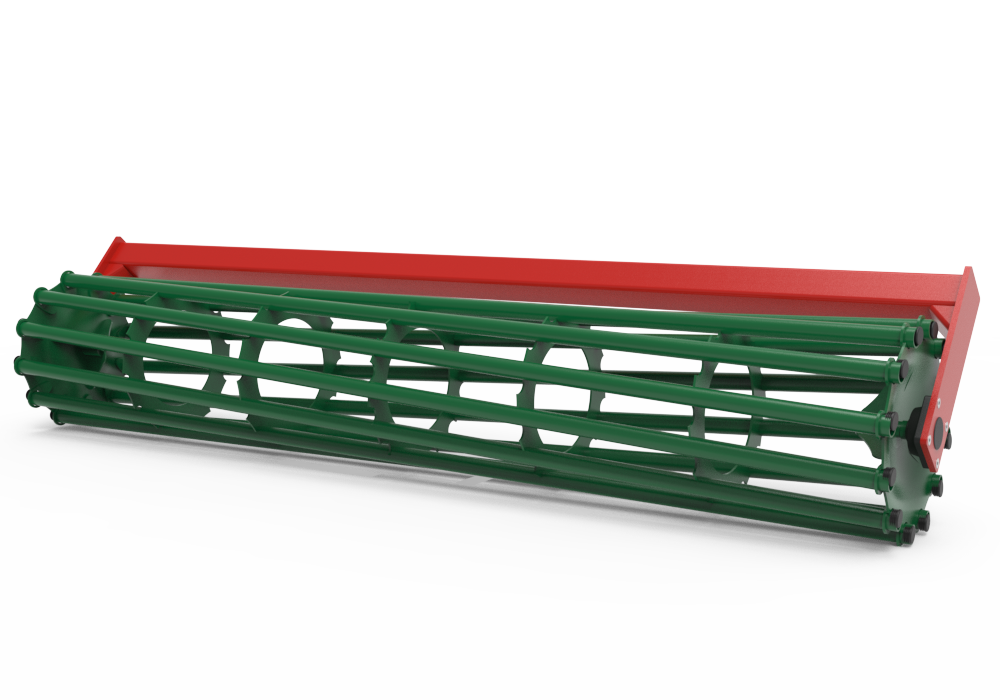

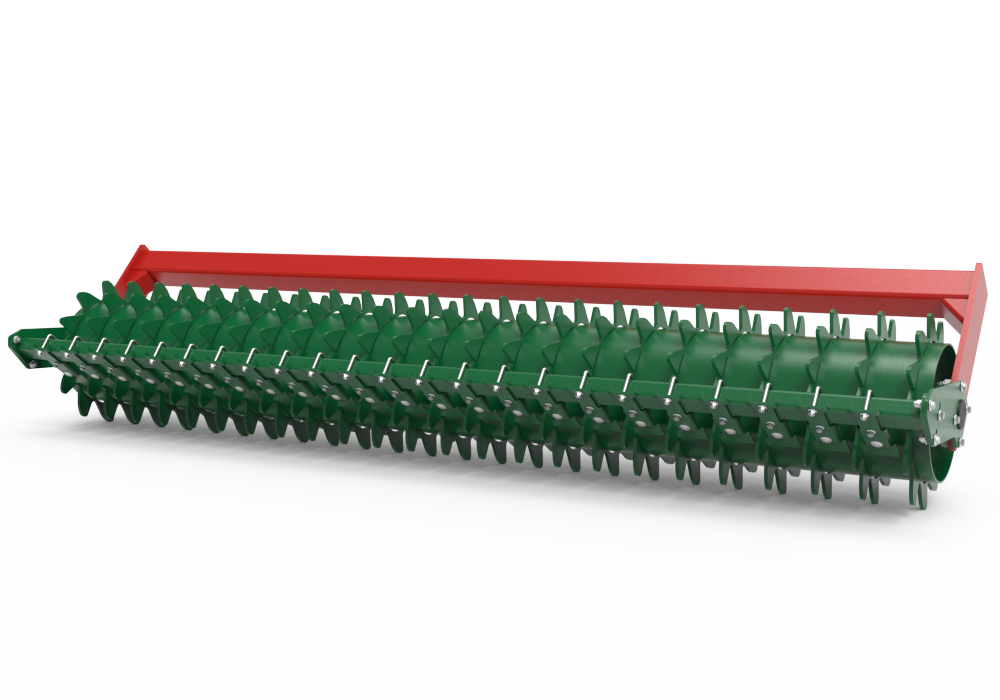

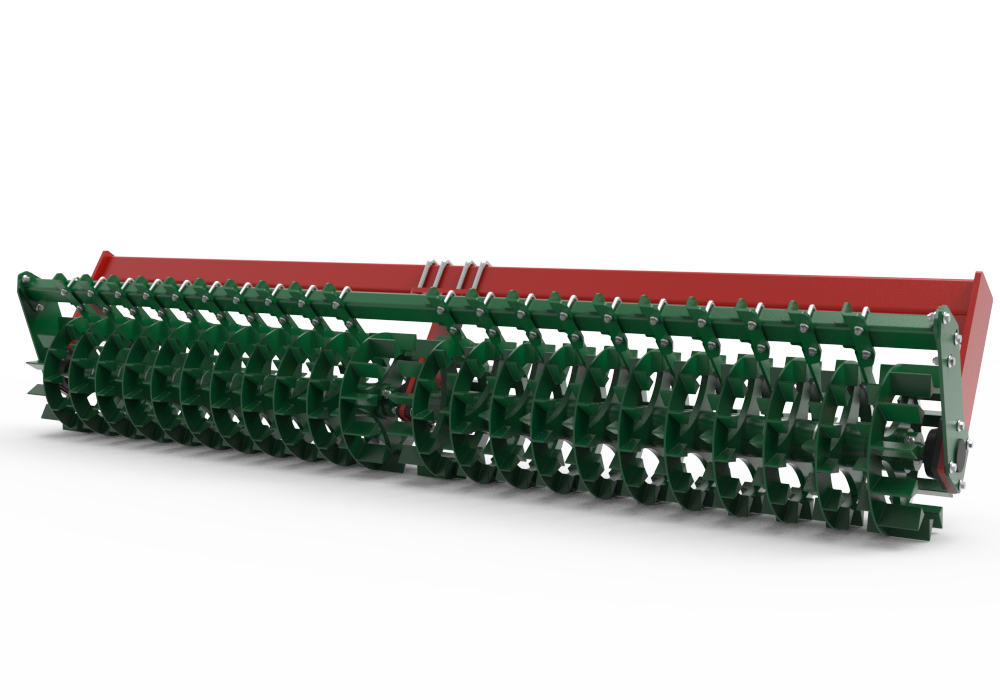

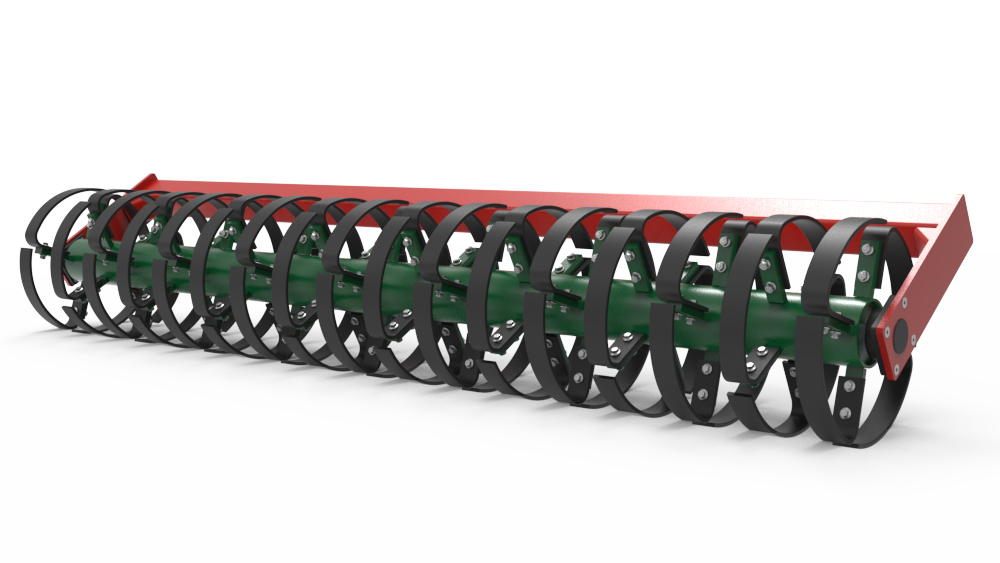

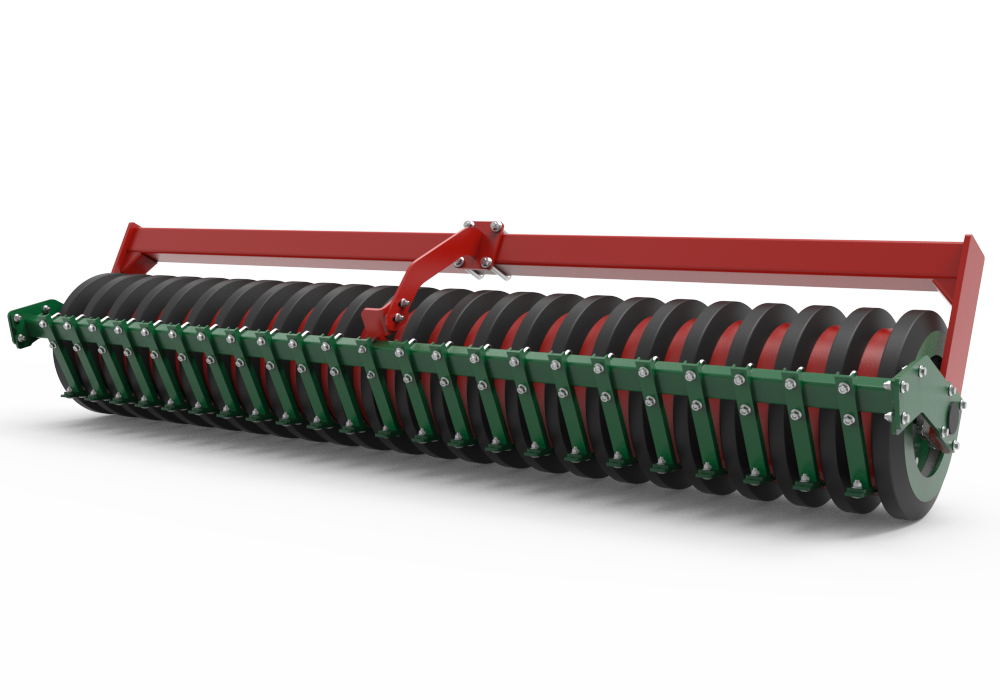

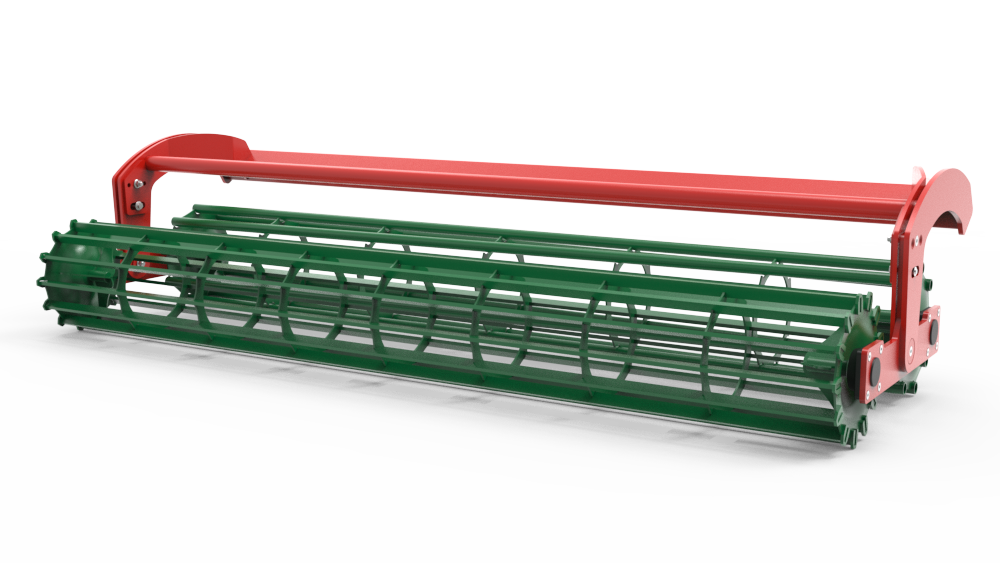

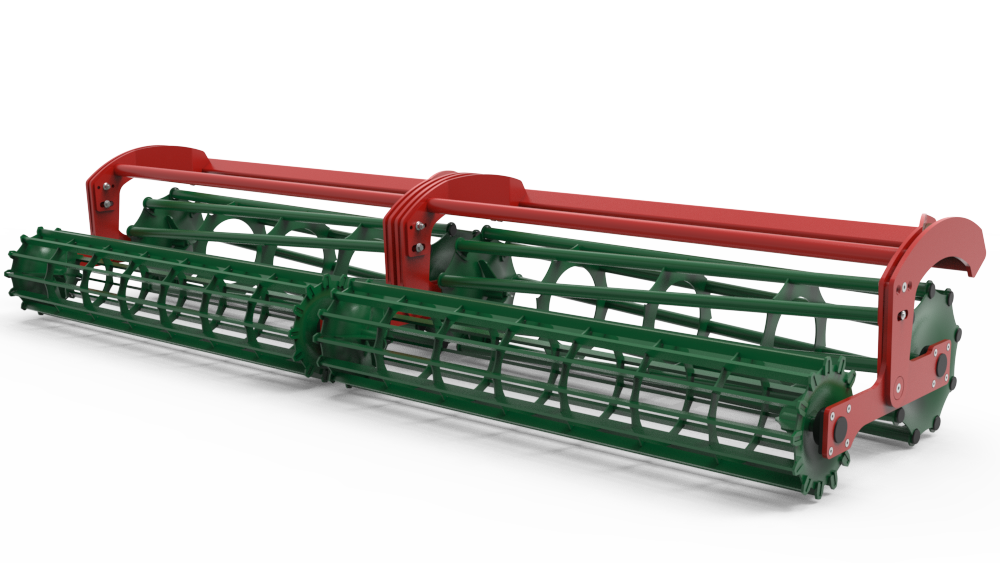

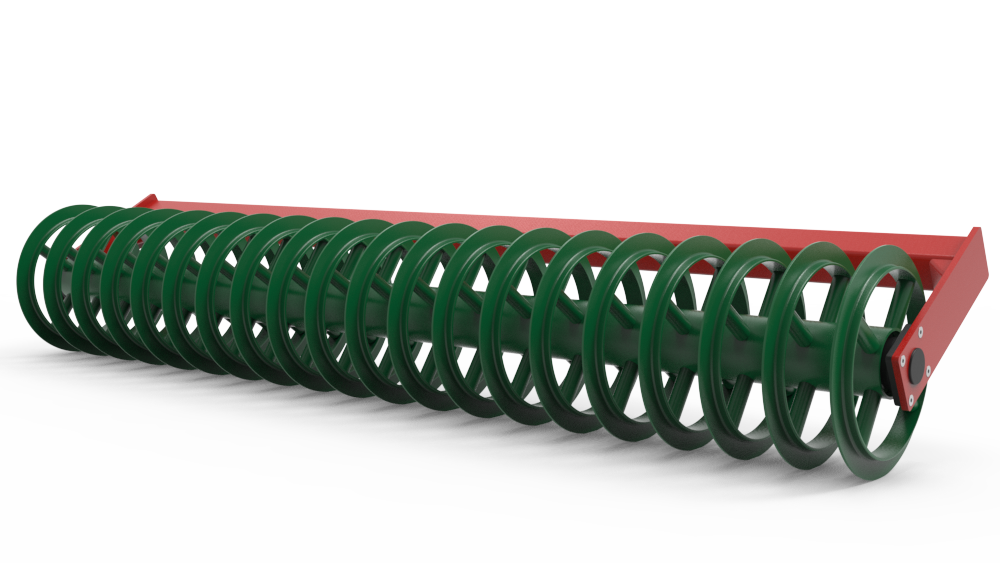

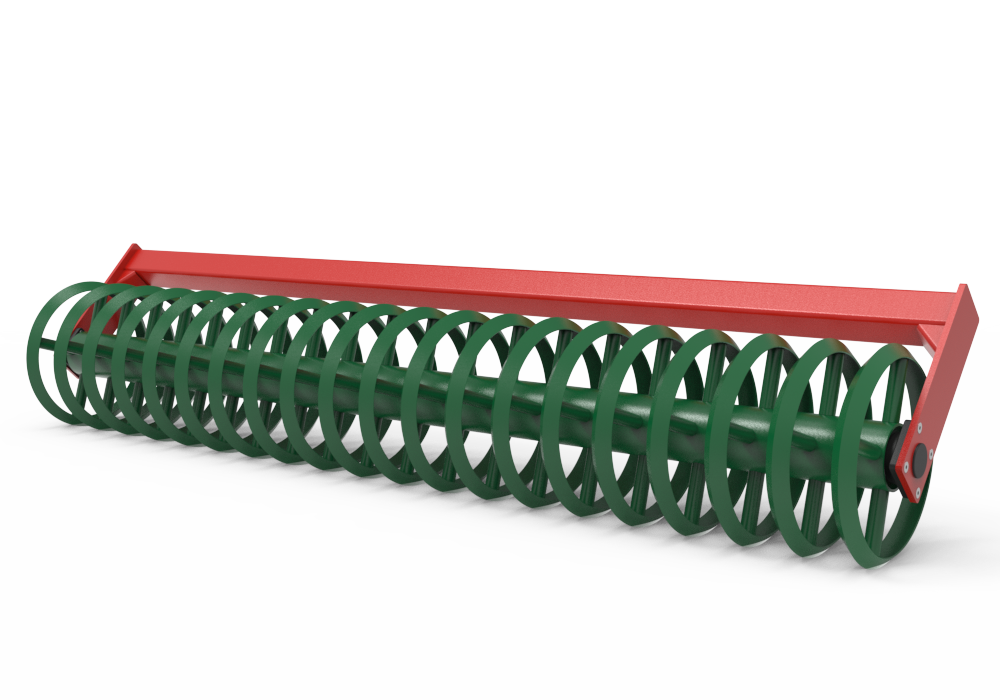

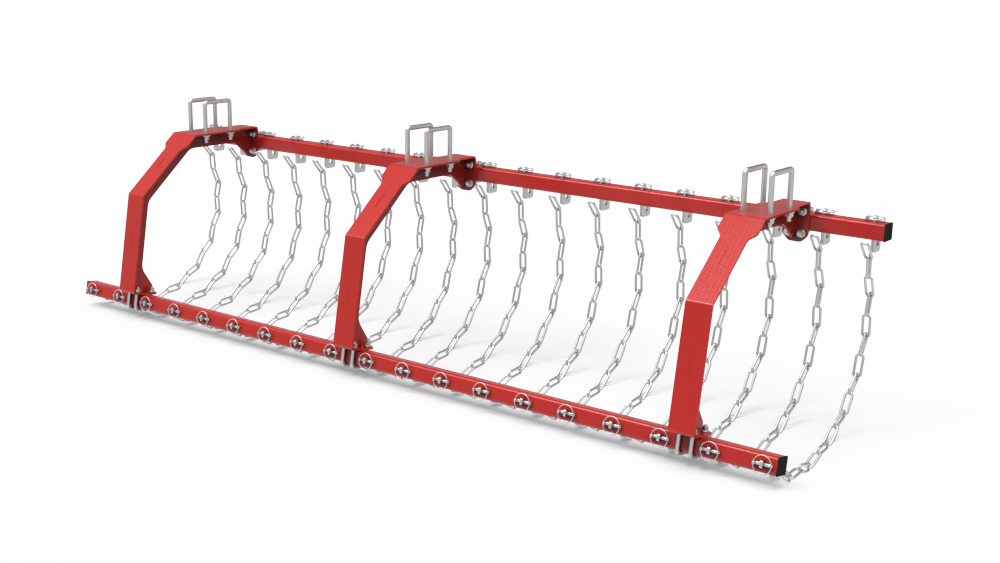

The last working section of the machine is the leveling roller. Achieve the most effective soil leveling and compaction by selecting a roller from a diverse range designed for various soil conditions. With this section, you will undoubtedly achieve optimal leveling results!

m.jpg)

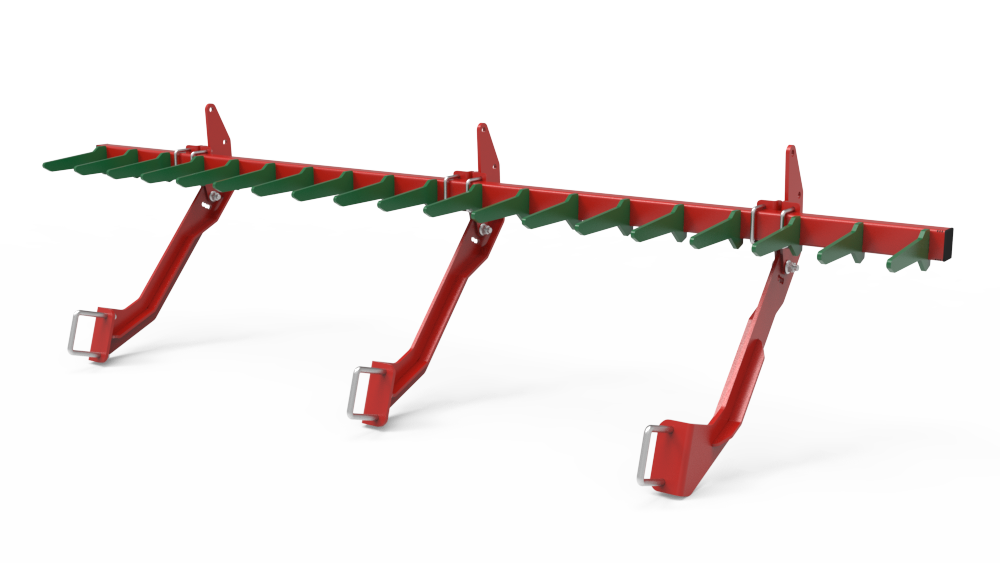

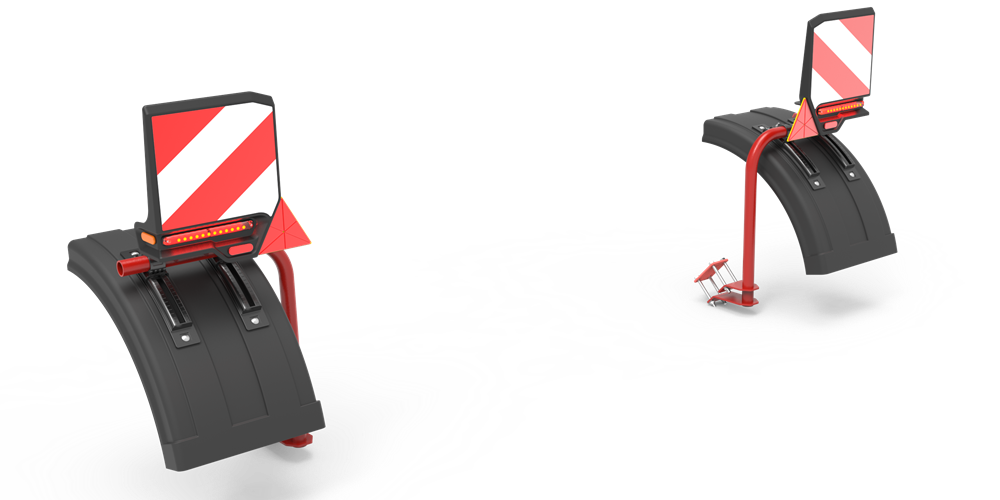

Active screens positioned at the edge of both disc sections limit the soil deposition zone by the outer discs, preventing the formation of ruts at the junctions of passes. In case of excessive penetration or encountering a significant obstacle, the screen brackets are attached to the frame using floating connections, allowing the screens to tilt upward during a collision.

The best results in soil crushing and leveling on the surface are achieved through the operation of a row of spring harrows. After a single working pass, the prepared soil is ready for seeding.

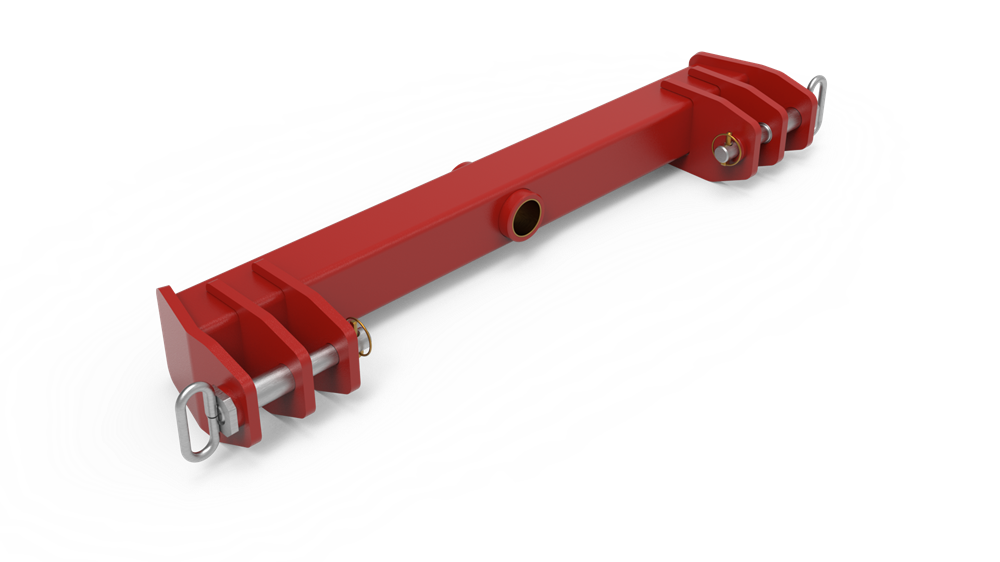

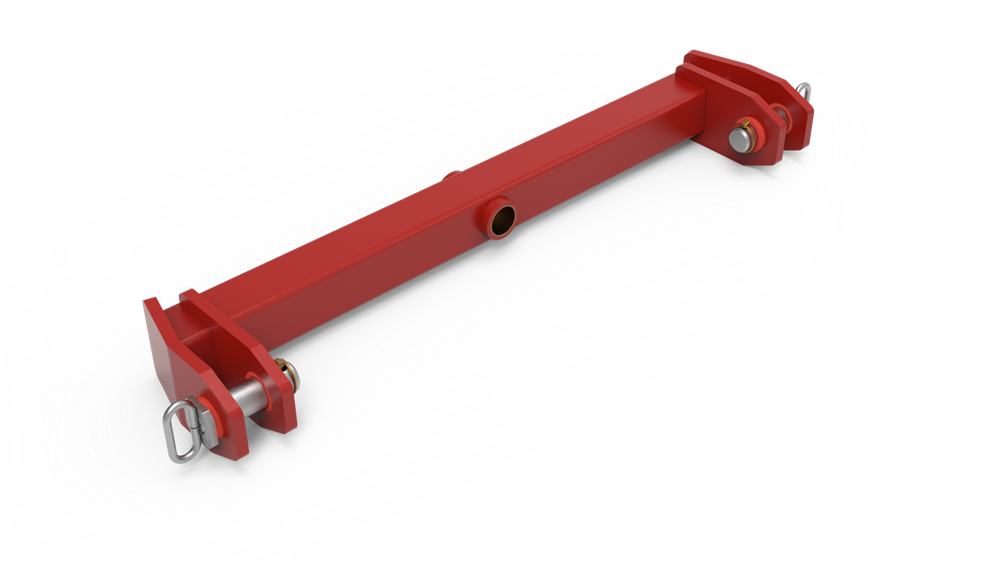

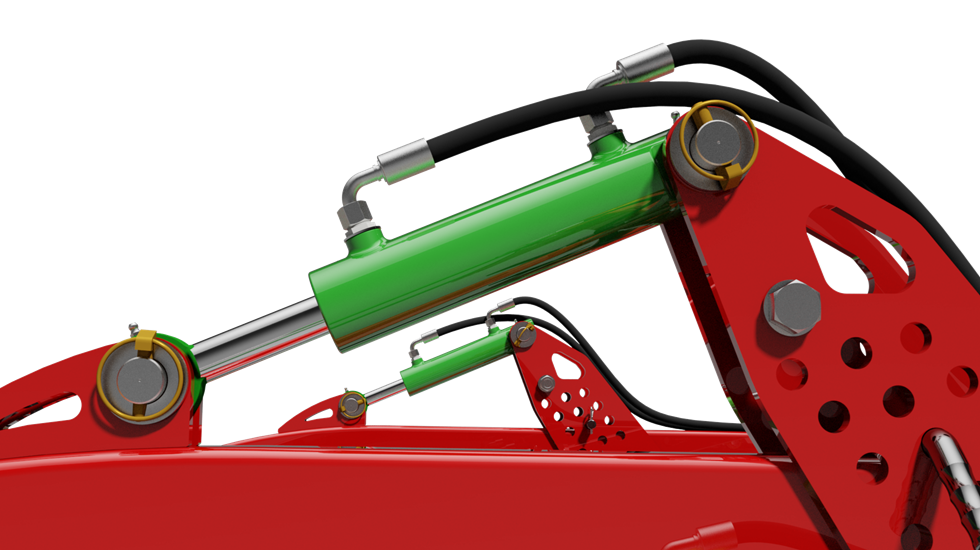

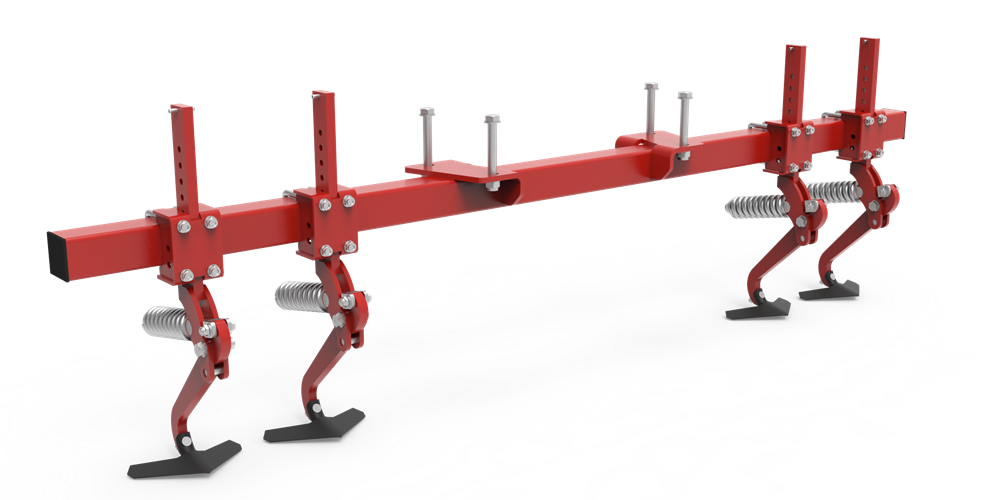

The system of pins locking the position of the rear roller arms, which allows for the adjustment of the working depth of the machine, can be equipped at any time with a hydraulic actuator assistance system. In this version, the working depth of the machine is comfortably controlled from the tractor cabin by manipulating the hydraulic system.

Main handle + BTH lighting

with homologation

only for the semi-suspended version of the 2018 cultivator

only for the semi-suspended version

only for the hydraulically folding, suspended version

only for the semi-suspended version

available only for plate type 'C' 560 mm