Our machines

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| BTC50 | 5.0 | 4680 | 180 - 220 | 40 | 4.0 - 6.0 | 14 |

| BTC60 | 6.0 | 5200 | 220 - 260 | 48 | 5.0 - 7.0 | 14 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

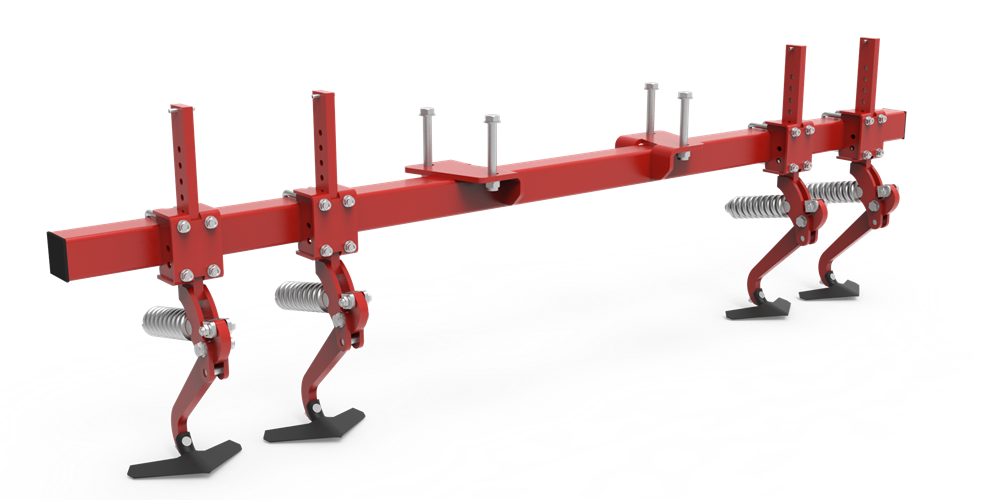

Semi-mounted disc harrows are machines designed for difficult tasks. They allow intensive and quick stubble cultivation. They are efficient with low fuel consumption. BTC harrows cope well with stubble with a lot of crop residues, as well as when returning fallow land to use.

Thanks to the integrated chassis, where the transport axle is placed in the middle (between the second disc section and the shaft), the machine has obtained an optimal mass distribution coefficient and exhibits exceptional agility during turning maneuvers in the field.

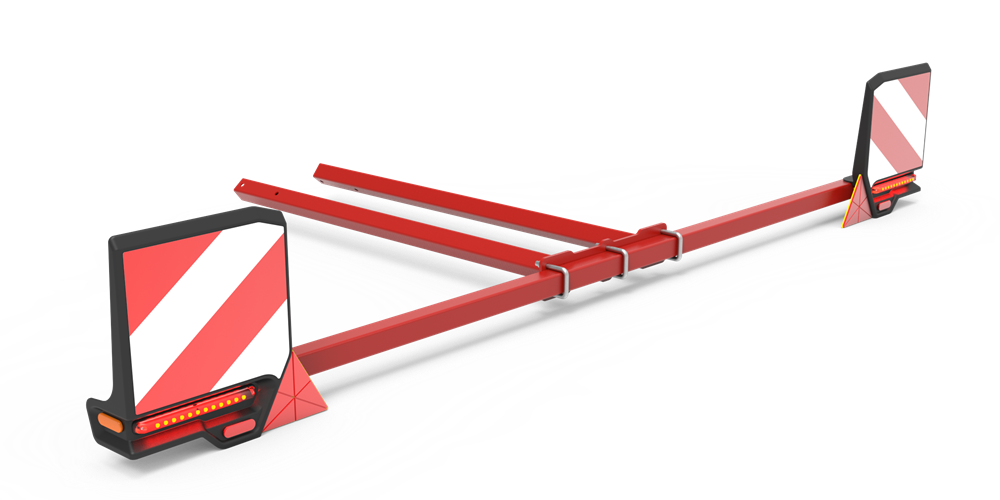

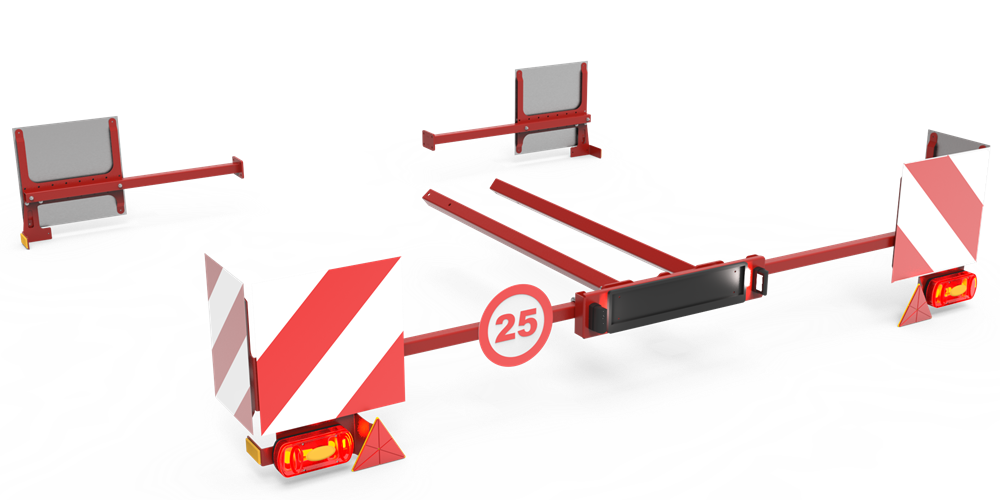

The running gear is equipped with hydraulic accumulators ensuring exceptional comfort of driving the set even on uneven ground. The pneumatic braking system supports the safe driving at high speeds on the road.

The time that the operator must spend on daily maintenance of the set has been reduced to a minimum. You can forget about bearing lubrication. Our disc harrows are standard equipped with maintenance-free hubs, in the heart of which work bearings identical to those used in the automotive industry. The entire system is protected with cartridge sealers, which are most effective in harsh field work.

The optimum working depth in given conditions is controlled by the wheels on the right and left working sections. They guide the discs smoothly at a given depth.

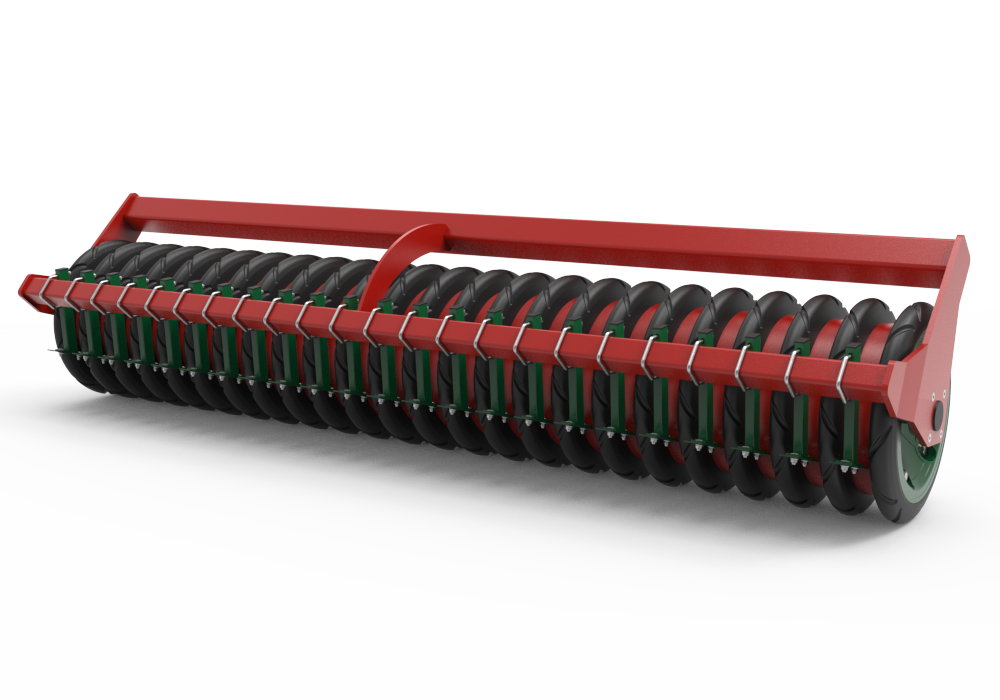

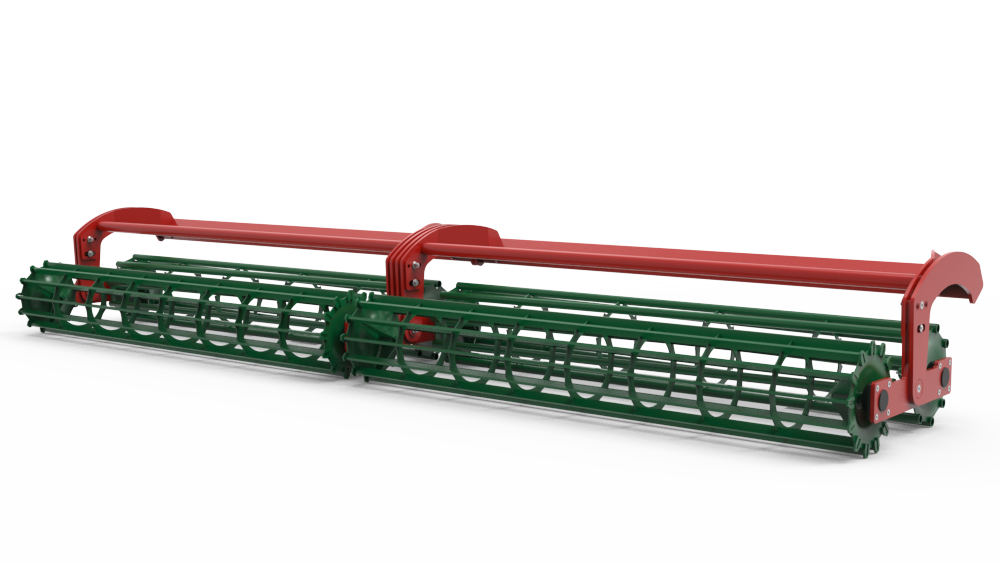

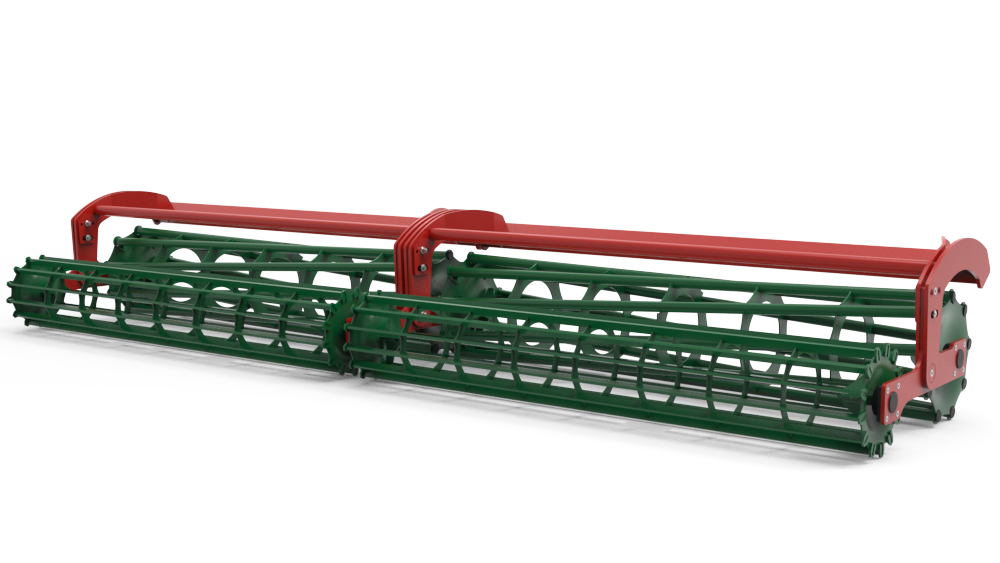

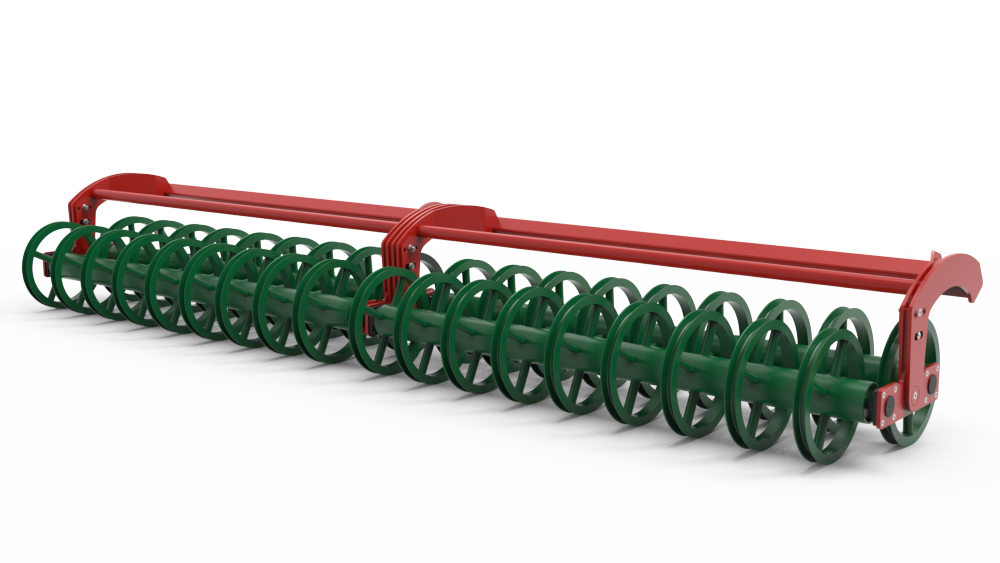

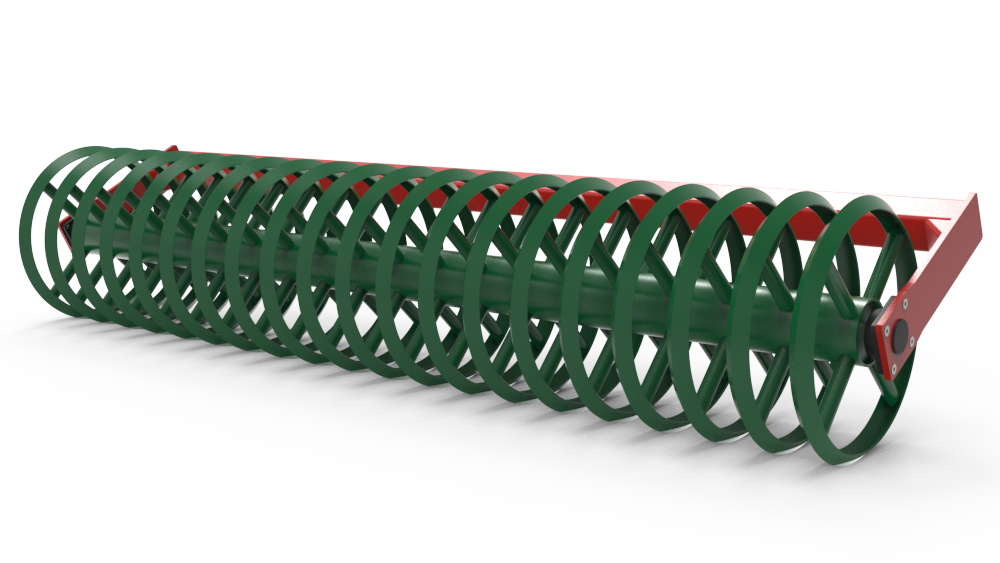

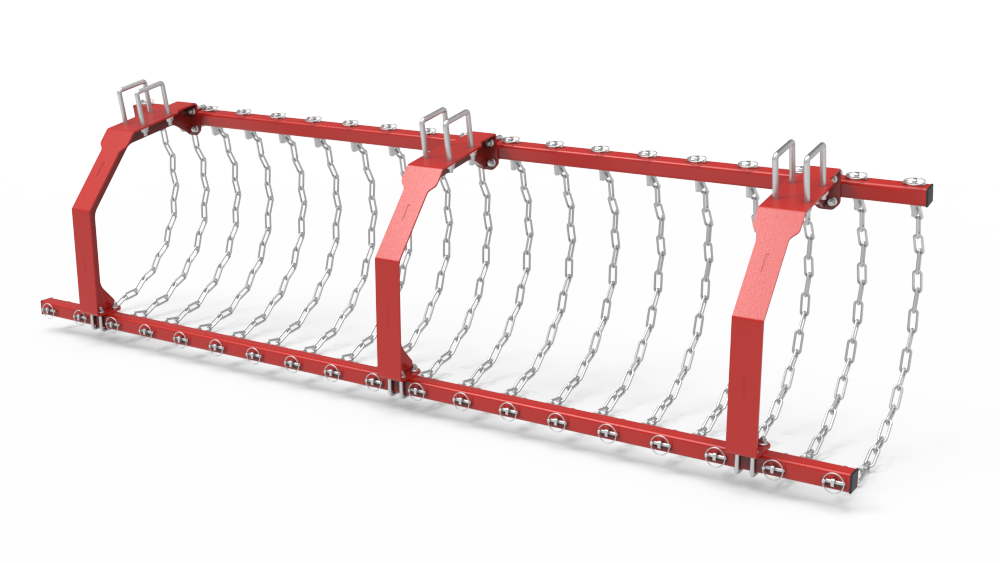

Option for tandem or single roller

Option for tandem or single roller

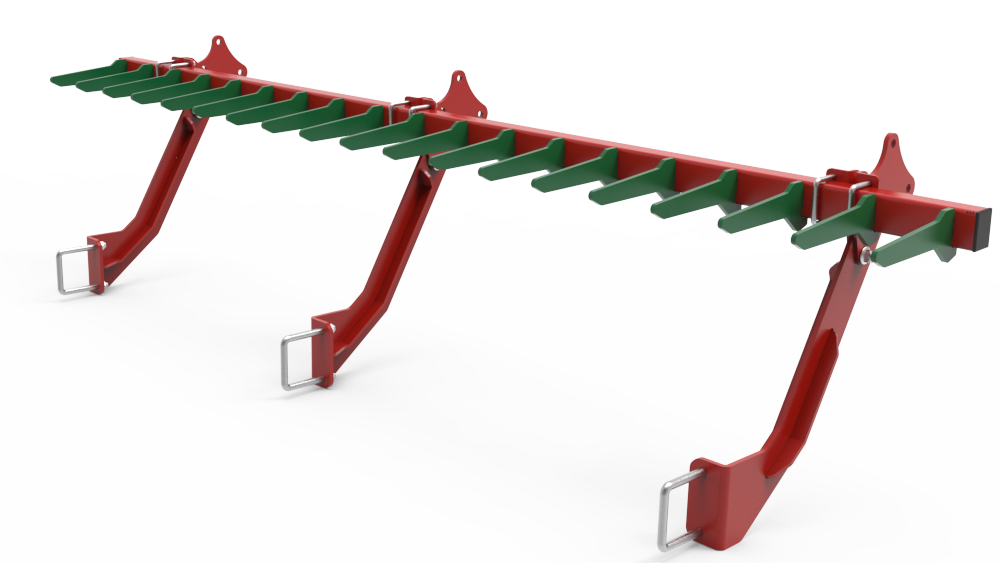

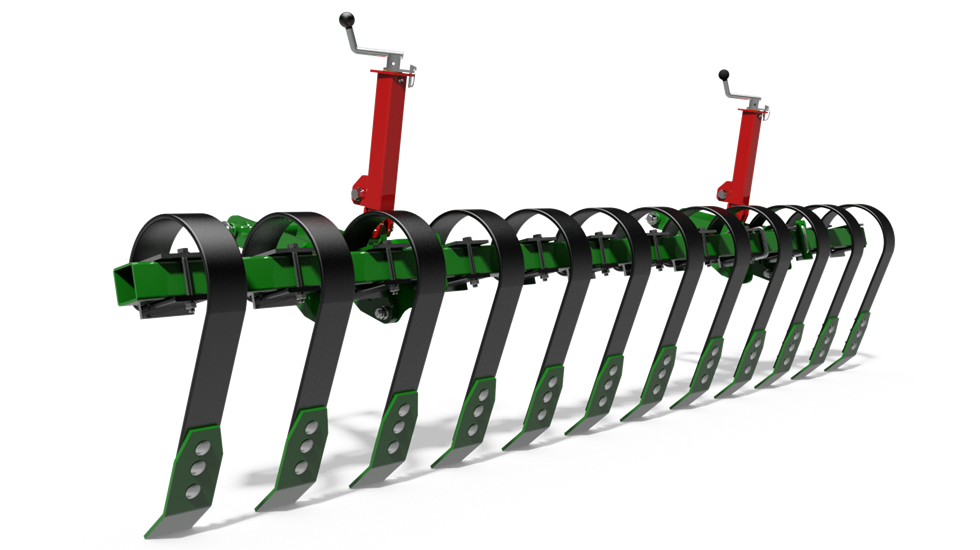

The best effect of crushing the soil and its leveling on the surface is obtained as a result of the work of the rake, the structure modeled on the leveling harrows. Flat, wide plates working on flexible teeth are arranged in a single section system. After one working pass, the soil is prepared for sowing. Precise, stepless adjustment of the position in relation to the rear shaft of the entire section is possible using four adjustment cranks.