Our machines

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of teeth (pcs) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|---|

| GRIZZLY X4 | 4.0 | 5800 | 240 - 380 | 14 / 10 | 30 / 32 | 4.0 - 6.0 | 35 |

| GRIZZLY X5 | 5.0 | 6300 | 340 - 480 | 18 / 12 | 38 / 40 | 5.0 - 7.0 | 35 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

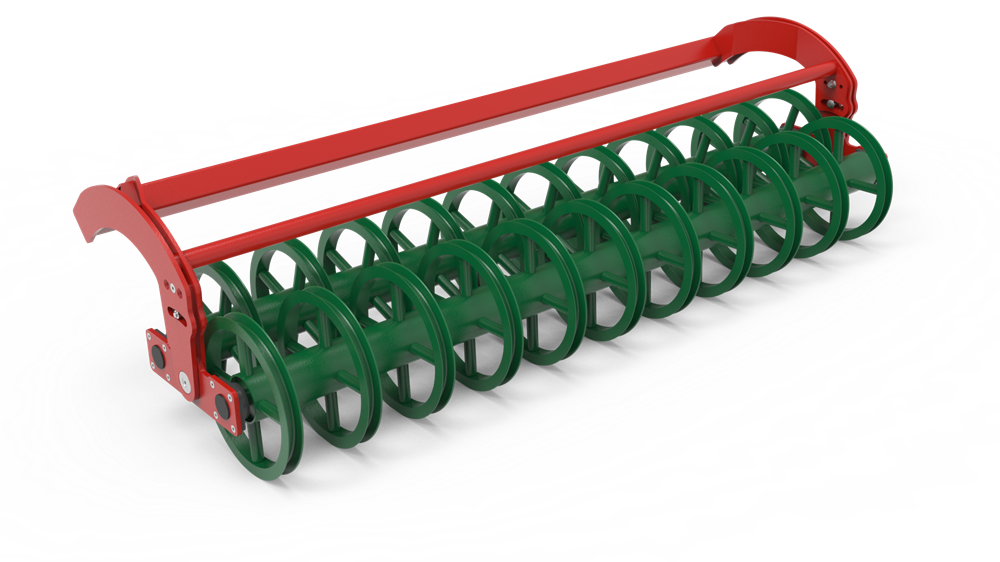

The multi-purpose GRIZZLY unit is used in no-plough cultivation. The machine has the features of a disc harrow and a stubble cultivator, thanks to which it is possible to thoroughly loosen and mix crop residues during one pass.

At optimally high working speeds, the properly adjusted rake and cutting angle of the discs enable the user to achieve maximum mixing efficiency of crop residues with the soil, simultaneously reducing the disc row spacing to 80 cm. The 510x4 mm diameter discs are mounted on a damped leg system with four rubber elastomers.

The most effective soil leveling and compaction can be achieved by choosing a roller from a diverse range of rollers designed for various soil conditions. Additionally, the roller is tasked with maintaining the set working depth of the cultivation section, which is adjusted using hydraulic actuators.

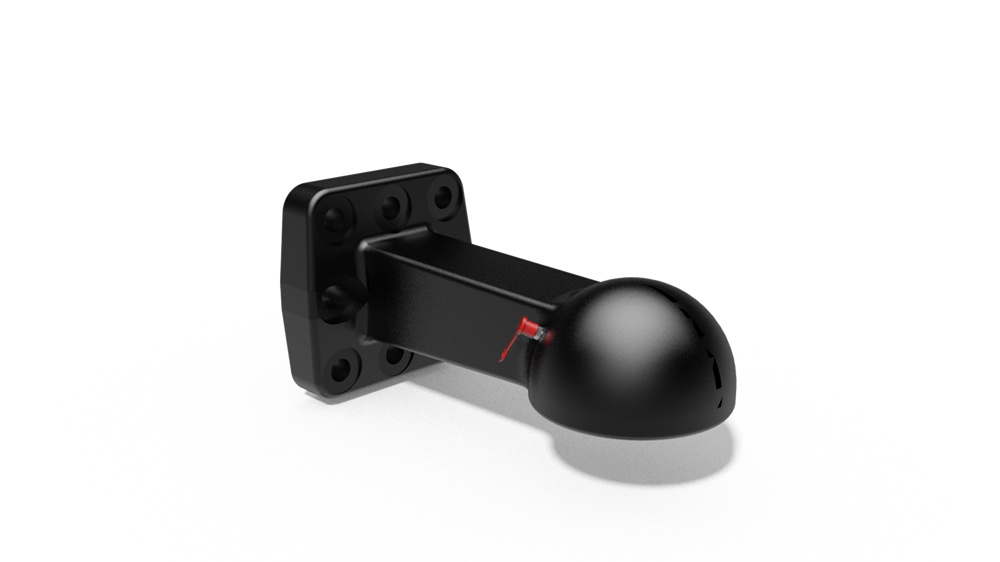

Rubber protectioneffectively protecting the discs from damage. These shock absorbers also further mitigate vibrations transmitted to the machine.

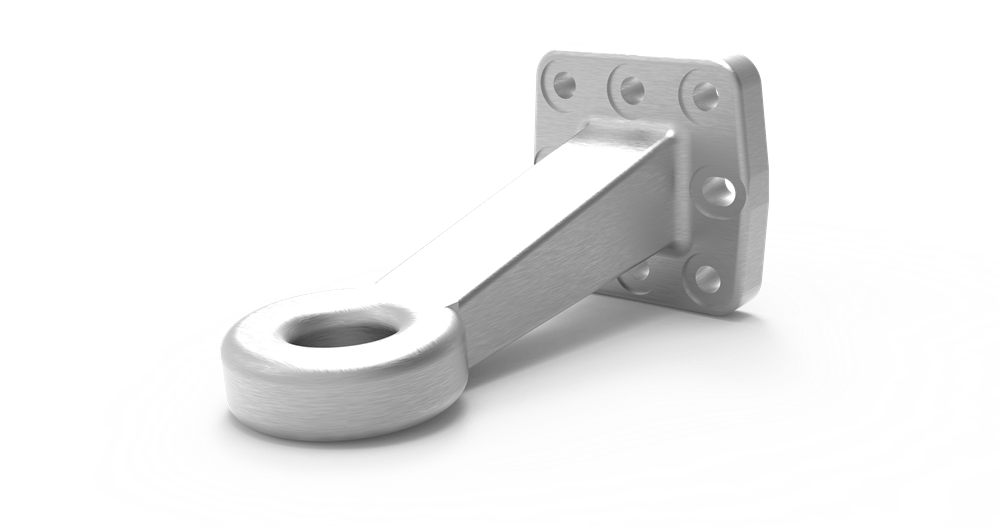

Arrangement of tines in three sections with double-sided blades and a long share adjusted at an appropriate angle to the ground in two rows allows for uniform and intensive mixing of crop residues. The ability to work even after removing the blades enables greater working depths to be achieved. With the proper spacing between the beams and ground clearance, excellent results can be achieved in any conditions.

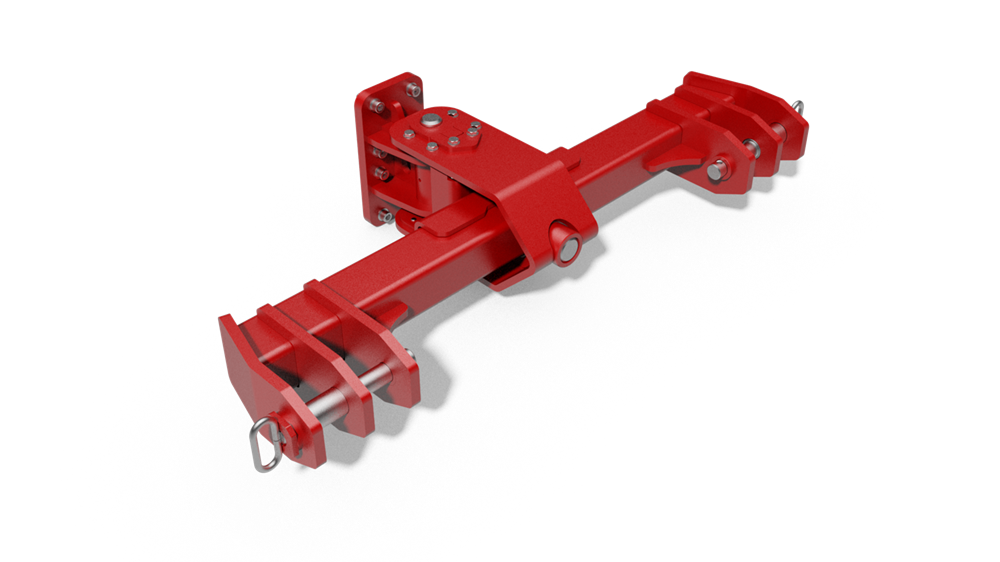

"Non-stop." These words encapsulate an entire philosophy based on efficient protection of working elements combined with user-friendly operation that requires minimal intervention from the operator. For every type of soil, whether in non-stony or slightly stony conditions, the most effective solution is our system of double springs that protect each tine.