Our machines

| Model | Width (m) | Weight (kg)*

Hoe coulters | Weight (kg)*

Disk coulters | Weight (kg)*

Double disk coulters | No. of coulters (pcs) | Power demand (HP) | Tank capacity (l) |

|---|---|---|---|---|---|---|---|

| SR250 | 2.5 | 580 | 720 | 750 | 19 / 21 | 40 - 60 | 450 |

| SR270 | 2.7 | 600 | 800 | 835 | 23 | 50 - 70 | 480 |

| SR300 | 3.0 | 620 | 820 | 860 | 23 / 25 | 60 - 80 | 550 |

| SR350 | 3.5 | 760 | 940 | 980 | 29 | 70 - 90 | 640 |

| SR400 | 4.0 | 860 | 1020 | 1070 | 33 | 80 - 100 | 790 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

The SR grain seeder was designed for sowing cereal seeds, papilionaceous plants and rapeseed. It also enables sowing catch crops. It can work as a stand-alone machine or in a set with various types of tilling sets equipped with a hydropack. Equipped with foot coulters, it is the best proposition for work in fields with a small amount of organic mass, while with disc coulters it works great even in mulch sowing conditions.

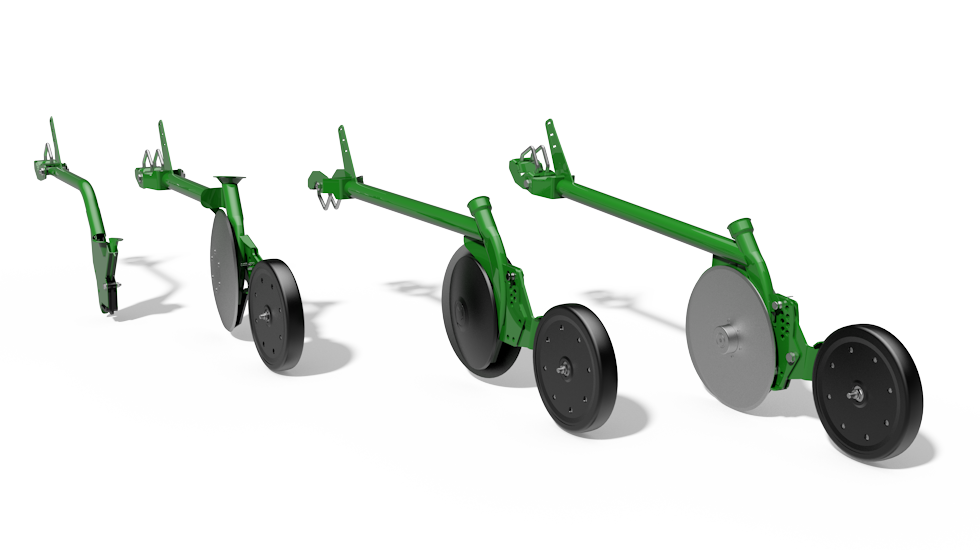

Choose a drill with one of the available coulter types.

To meet the needs of small and medium-sized farms, technologists and designers have developed a row seed drill in four versions of working sizes: SR250 (2.5 m), SR270 (2.7 m), SR300 (3.0 m), SR350 (3.5 m) and SR400 (4.0 m).

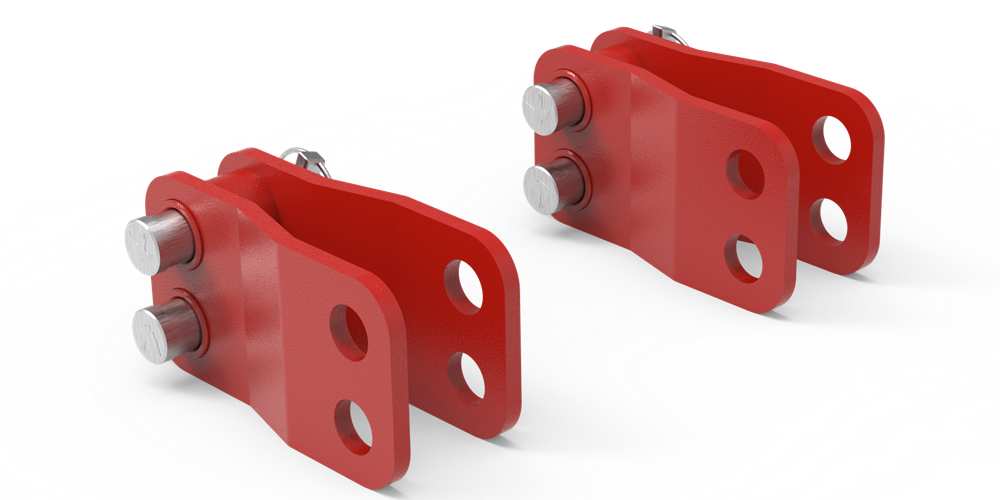

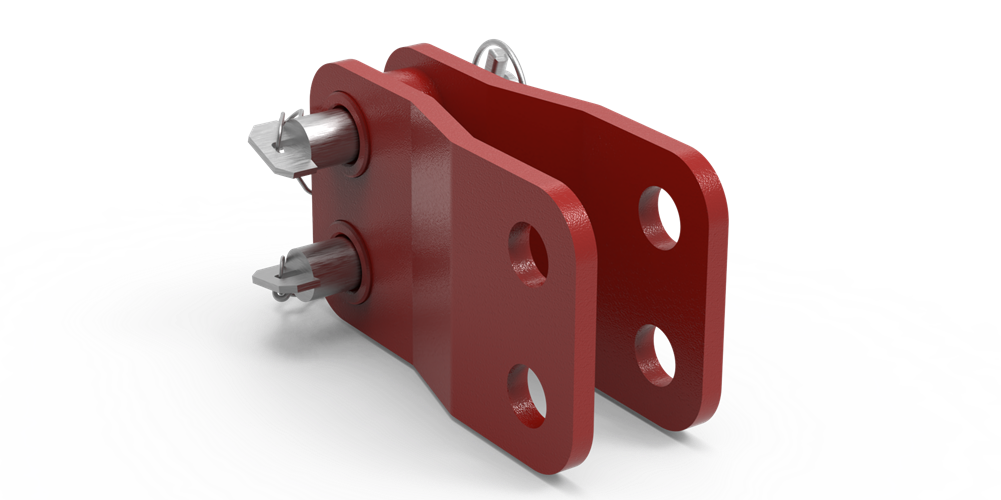

The coulter has been combined with a mounted rubber wheel that determines the level of coulter penetration. Depth adjustment is facilitated by a comfortable pin secured with a cotter pin.

The scale built into the central plunge adjustment system (version with foot coulters) and the seed coulter pressure will allow you to achieve precision and repeatability of settings. You will always be able to perfectly set your machine to the specific type of grain and real soil conditions.

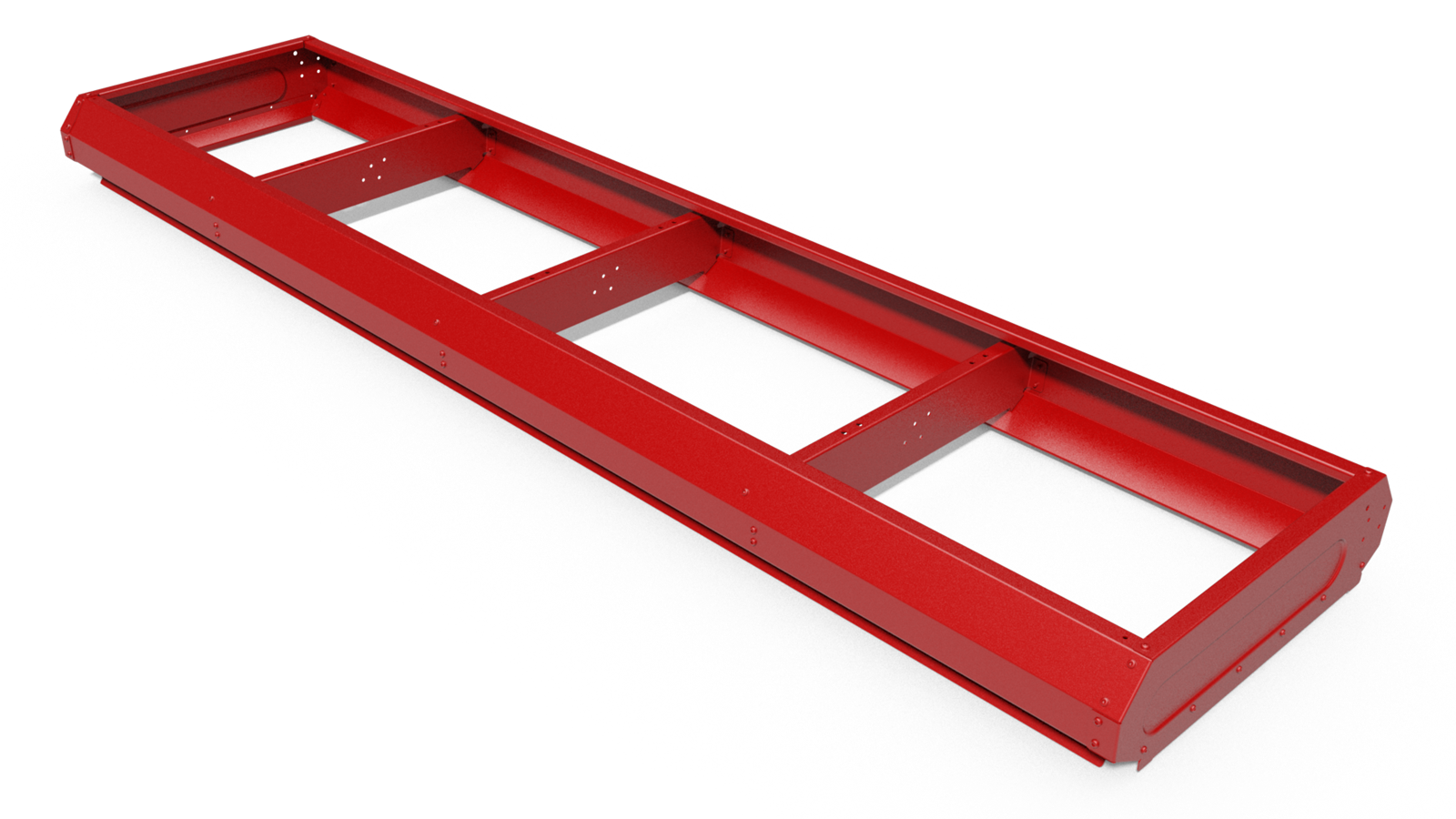

Solid and compact frame construction combined with a large capacity grain tank made with riveted steel technology of extra pressed steel, which ensures high durability and long life of the machine, designed so that the seeder can work as an independent machine and in a set after coupling with aggregates equipped with a hydropack . The tank is equipped with a float level indicator for constant control of the amount of grain.

Continuously variable transmission - the heart of the seeder - built on the basis of a cam system with directional clutches. The settings are made on the basis of a large, convenient scale referring to the fertilizer chart display. High-quality components working at the heart of the gearboxes ensure long life with high precision in dosing grain.

For your convenience, AGRO–MASZ seed drills are equipped with hydraulically controlled disc markers, amortized and additionally protected against damage due to shear bolts. They also work well in difficult conditions of stony fields.

The wide platform with fold-out steps makes loading easier, and the side fold-out step is extremely useful when loading from a trailer. This ergonomic design provides the operator with safety not only when loading grain but also during the daily operation of the machine.

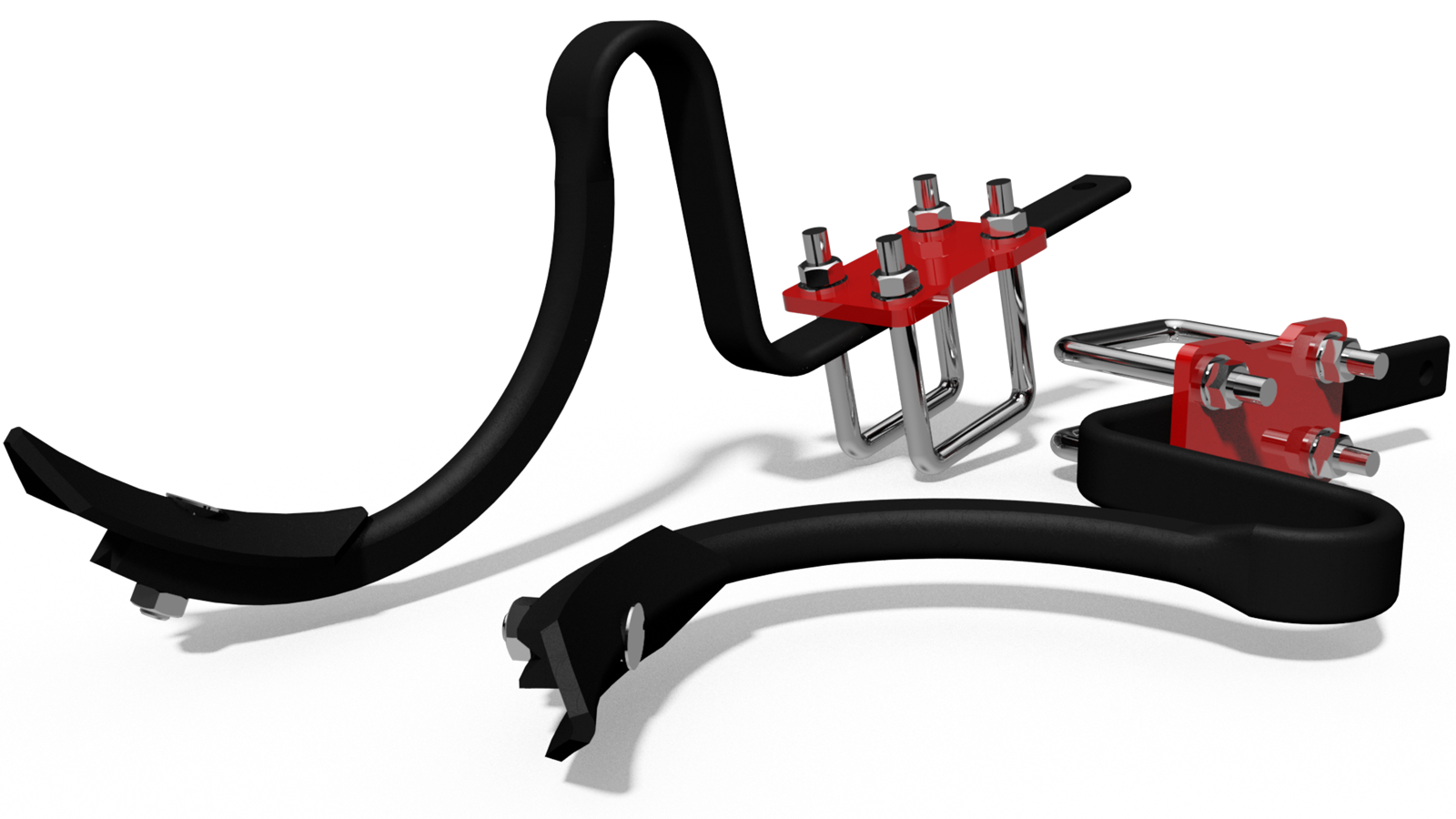

The spring harrow with simple mechanical adjustment of the working angle is adapted to work even with a large amount of straw lying on the field surface. L-shaped spring tines perfectly cover ridges and level the field surface.

At the bottom of the grain tank, between the gaps supplying grain to the sowing apparatus, grain dividers are mounted. Made of hardened plastic, the elements with a characteristic pyramidal shape are responsible for even distribution of the sown material and protect against spilling of grains with a small amount in the tank. At the same time, when sowing seeds of fine-grained plants, such as rapeseed, they allow sowing the required dose without having to fill the tank with excess grains.

An advantage for farmers using seed drills with coulter coulters, ensuring the most even sowing effect in the belts behind the wheels of the seeder is the use of extreme disc coulters.

The seeder is equipped with the universal sowing wheels as standard. The machine can be optionally equipped with the sectional sowing wheels (for achieving the highest possible dosing precision) dedicated to the farms focused on the cultivation of the fine-grained plants in particular.

The AM - PLUS controller is an automatic path controller for seed drills using electrically controlled mechanisms for creating technological paths, including pre-emergence paths. Technological paths are made for later work with a sprayer or fertilizer spreader. The calculation of trips is done automatically, using a sensor. A clear large display with automatic brightness adjustment and a backlit keyboard allow for comfortable work in all lighting conditions.

The machine equipped with a computer gives the operator the widest range of possibilities, and the sensor system integrated with it sends in the present time additional information about the sowing parameters - among others by alerting the operator with a low grain level in the seeder box.

SI11404 Complete mounting RAM

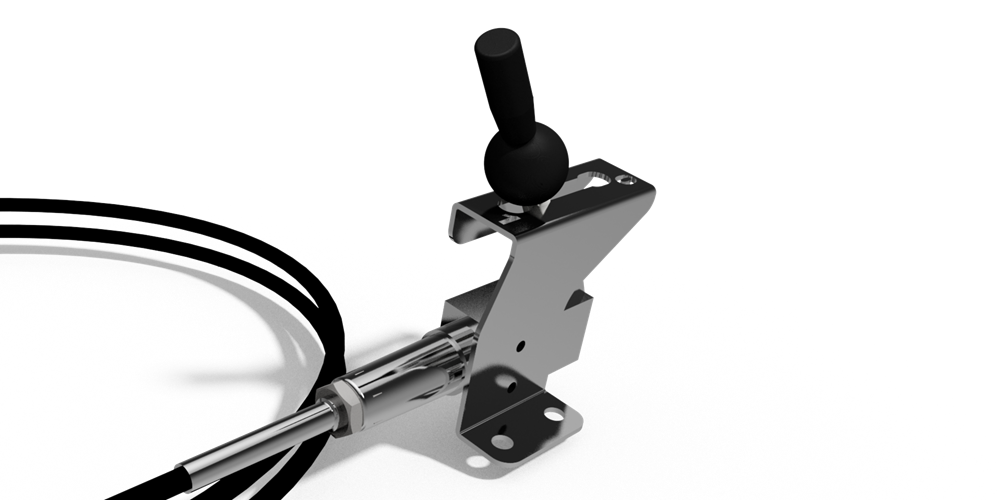

In addition to the mechanical controller and the computer, it is possible to equip the seed drill with an electric controller dedicated to tramlines.

Extension for hydraulic

SR250 SR270 SR300 SR400

Instruction manual for AD20 controller (PL)

Instruction manual for AD20 controller (EN)

Instruction manual for AD20 controller (DE)

Instruction manual for AM PLUS controller version 1.1 (PL)

Instrukcja obsługi sterownika AM PLUS wersja 2.0 (PL)

Instruction manual for AM PLUS controller version 1.1 (EN)

Instruction manual for AM PLUS controller version 1.1 (DE)

User manual for the W-1 controller

Instruction manual for the T1 controller

Menu diagram of the AD20 controller (PL)

Menu diagram of the AD20 controller (EN))

Menu diagram of the AD20 controller (DE)

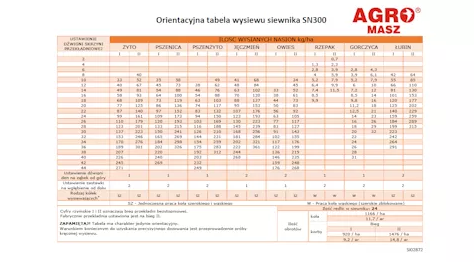

Table of seeding SR270 (EN)

Table of seeding SR300 (EN)

Tabela wysiewu siewnika SR350 (PL)

Table of seeding SR400 (EN)