Our machines

| Model | No. of units (pcs) | Weight (kg)* | Working width (m) | Capacity (l) |

|---|---|---|---|---|

| SP230 | 8 | 65 | 2 - 6 | 230 |

| SP400 | 8 | 100 | 2 - 6 | 400 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

The film presenting a shot test

Dosage change video

The video showing the installation of the condition sensor

CoEF seeding factor film

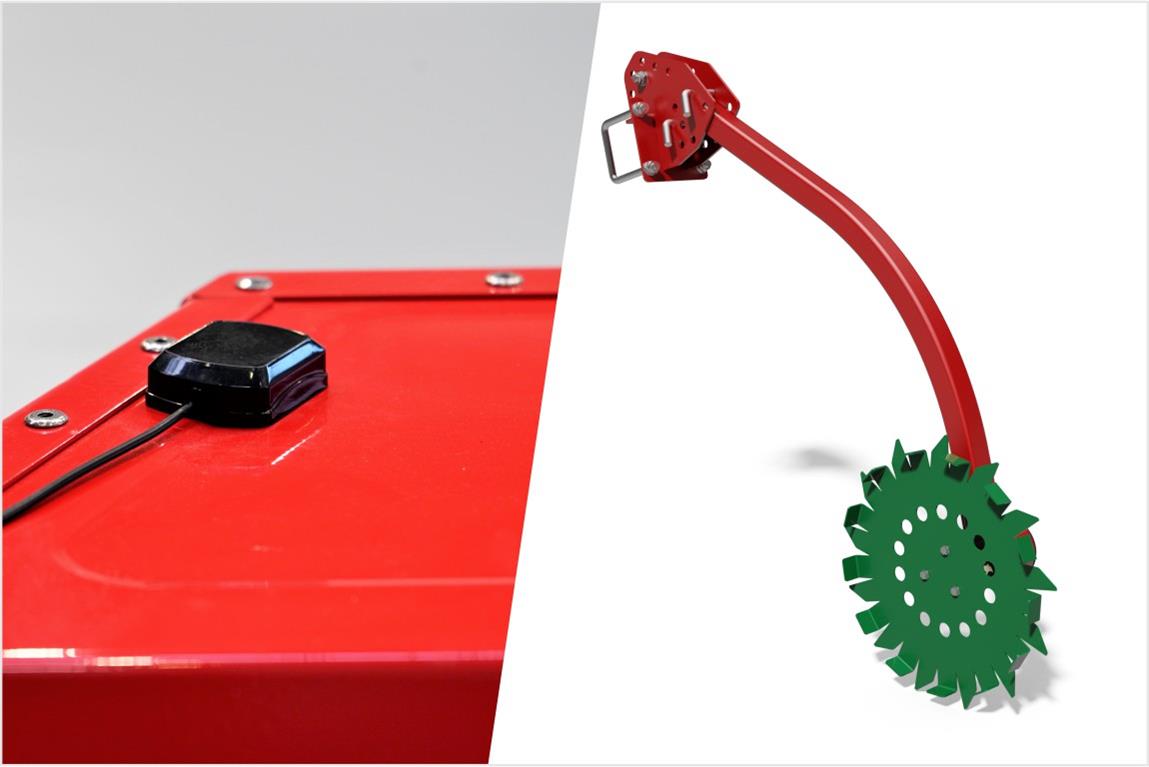

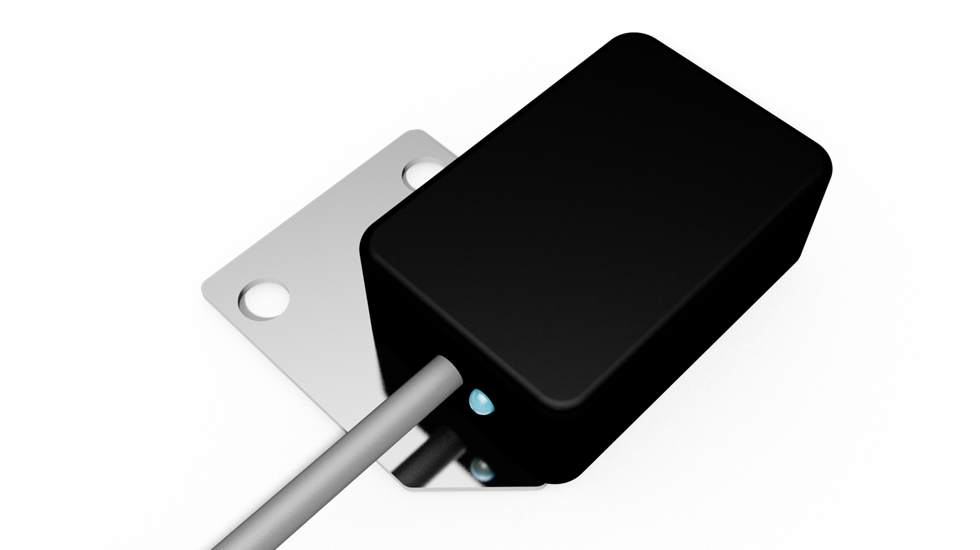

ISEn status sensor - for seeder equipped with a depth gauge wheel

Working width

FAnP blower power adjustment option

ISEn status sensor for GPS-equipped seed drill

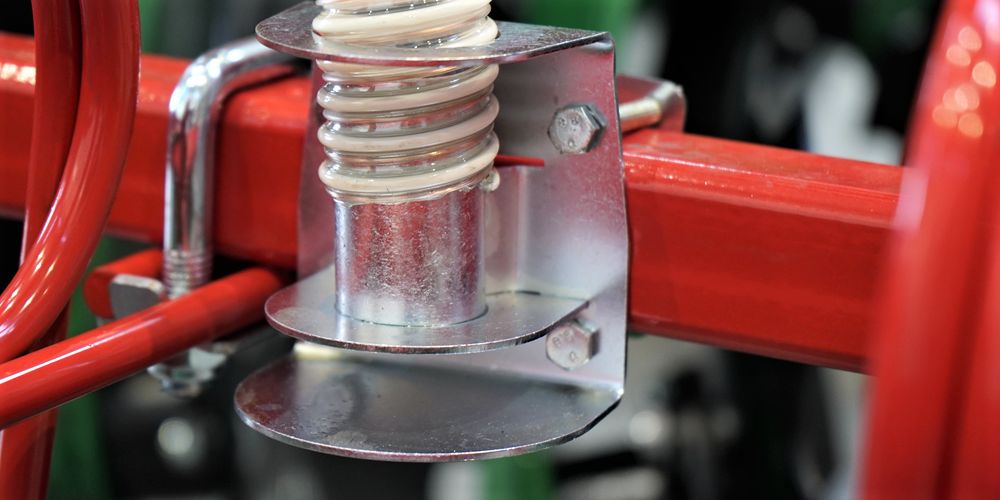

Adjustment of the sensor on the uHEE tracking wheel

uHEE for seeder with GPS

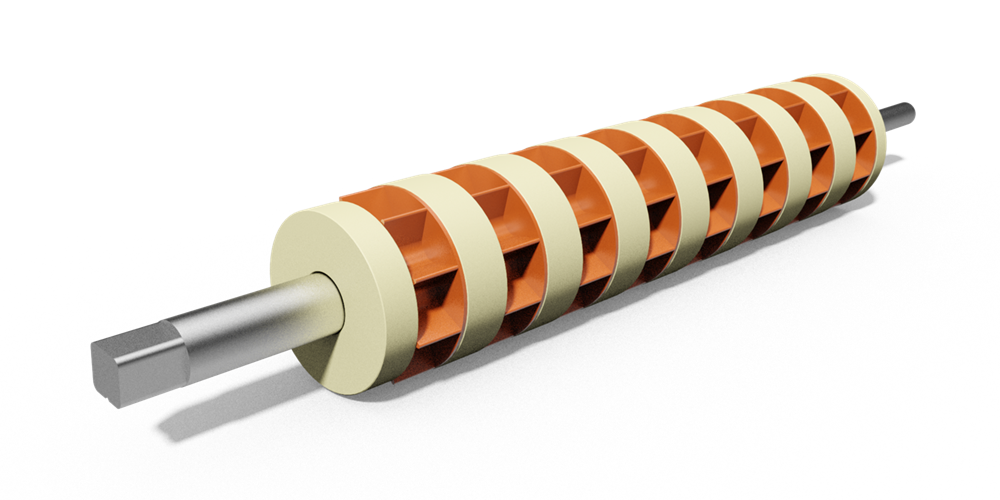

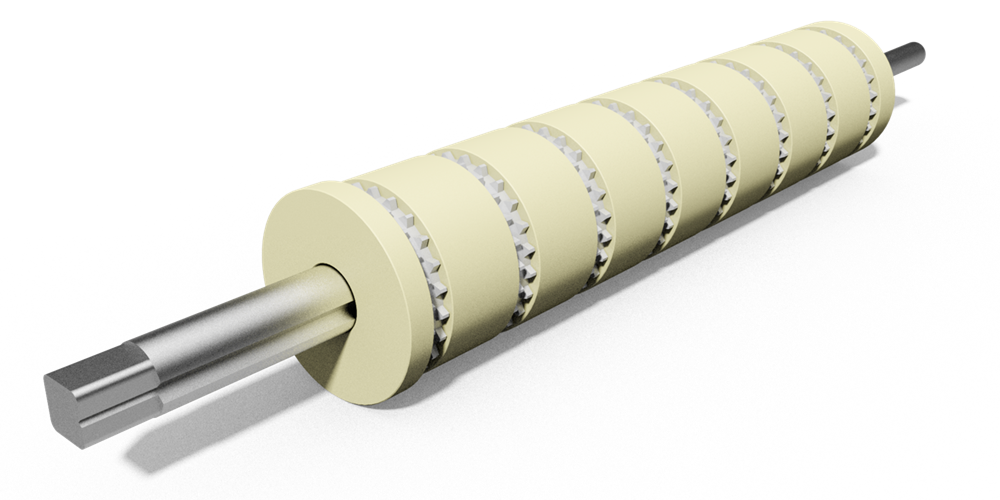

The machine allows for spreading catch crops of various types and sizes of granulate. The seeding system is an electric unit that drives a universal seeding shaft with a wide speed adjustment range. The grain is dosed from a 200 or 400 liter tank. The seeding shaft transfers the seed to an eight-channel distributor, where it is pneumatically transported to flexible seed hoses made of plastic, terminated with plates. Two electric booster blowers are responsible for grain transport.

A dedicated computer is responsible for accurate metering of the seed. The user-friendly module allows the operator to control and adjust basic seeding parameters.

The great advantage of this method of spreading the sown material is the certainty of its even distribution in the field regardless of weather conditions (wind) prevailing during the agrotechnical procedure.

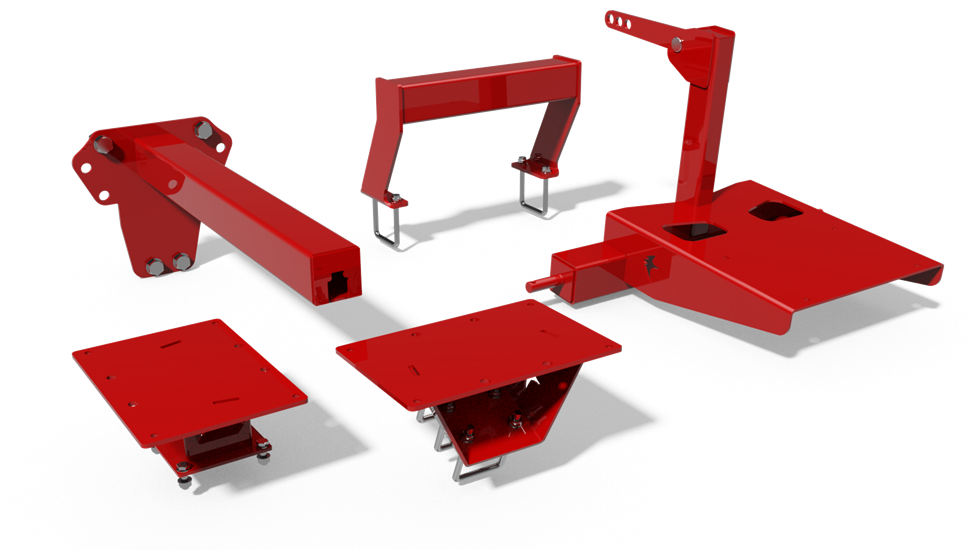

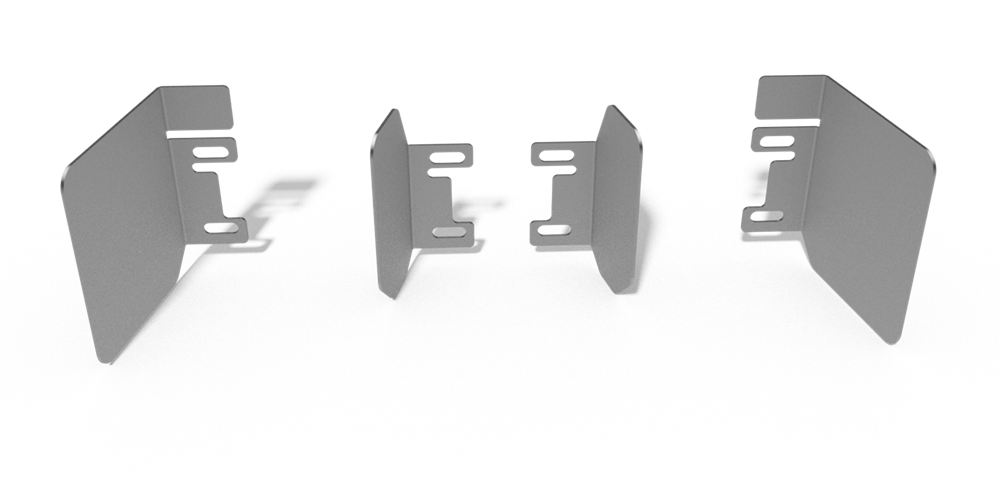

The spreading plates are mounted on a special beam. They can be arranged at different intervals depending on the working width of your machine on which the seeder is mounted. SP is dedicated for aggregates with a working width in the range from 2 to 6 meters.

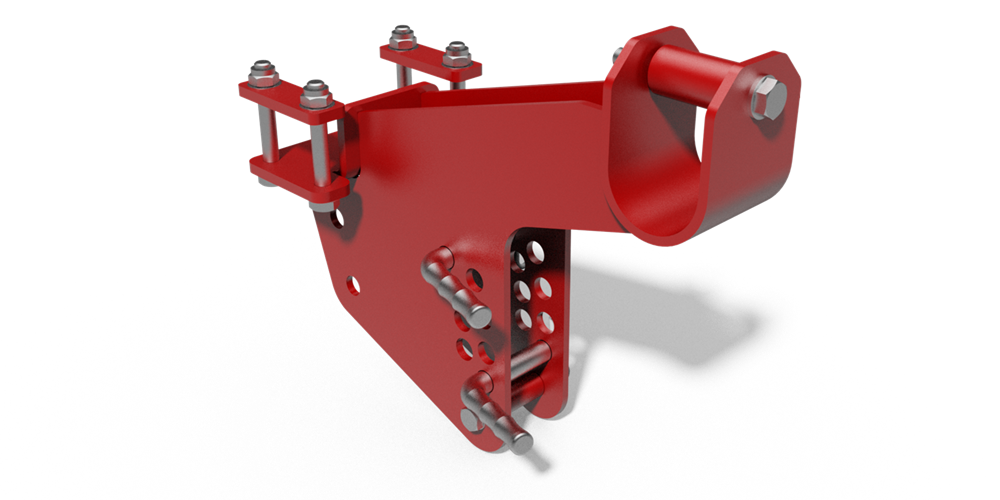

The standard complete SP set includes a seeder with complete electrical installation and mounting plate, flexible seeding lines (20 m), eight seeding plates and a plate beam with handles.

Menu diagram for the AP2 controller (PL)

Menu diagram for the AP2 controller (EN)

Menu diagram for the AP2 controller (DE)

Menu diagram for the AP2 controller (LT) (LT)

The machine equipped with a computer gives the operator the widest range of possibilities, and the sensor system integrated with it sends in the present time additional information about the sowing parameters - among others by alerting the operator with a low grain level in the seeder box.

Steps mounted on the machine

OPTION TO "EXTERNAL CONTROL PANEL"

BTC30, APR, AP, AP NON-STOP 21, 30, RUNNER 30, 35, APSH40, APSH50, APSH60, BT40, BTH SEMI-MOUNTED VERSION, BTC50, BTC60, AT (VERSION 2018), BM75, GRASS 300, TROL 30.

for BM75

Additional roller

Additional roller

required for Grass 300

for AD2 computer