Our machines

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of discs (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| FASTER CUT 30 | 3.0 | 2260 | 130 | 24 | 5.4 | 4 |

*The given weight is approximate and may differ from the actual one depending on the equipment and configuration.

The ultra-shallow cultivation involves cutting crop residues at a depth of 0 - 4 cm. This shallow cultivation allows for a significant reduction in water evaporation from the soil and initiates faster germination of weeds and self-sown plants, which can be destroyed in subsequent mechanical agricultural operations. Ultra-shallow cultivation is consistent with the principles of the "European Green Deal," which promotes the reduction of pesticides, herbicides, and synthetic fertilizers.

The purpose of the cutting shaft is to shred straw and crop residues. This allows for a more thorough mixing of the soil during cultivation. The blades of the shaft are sharpened on both sides and made of durable steel, additionally enhanced through heat treatment. This construction enables long-term operation without downtime. The working depth is adjustable using hydraulic cylinders.

Specially designed shape and plate arrangement allow for complete undercutting of the cultivated surface. The "Faster" type plate intensely shreds corn or rapeseed crop residues. Depth adjustment is done using Roman screws, and it is possible to independently set the depth for the front and rear rows of plates.

Active side screens located on the edge of both disc sections limit the area of soil depositing by the outer discs, preventing the formation of ruts at the connections of the passages. In the event of an excessive depression or encountering a large obstacle, the screen holders are attached to the frame by means of floating connections, allowing the screens to tilt upwards during a collision.

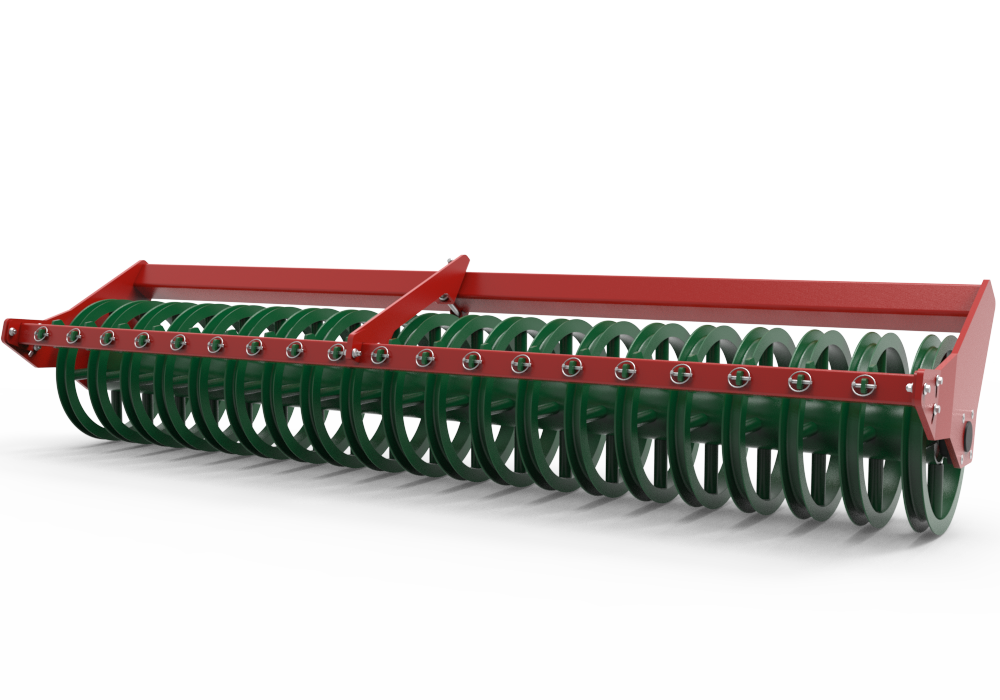

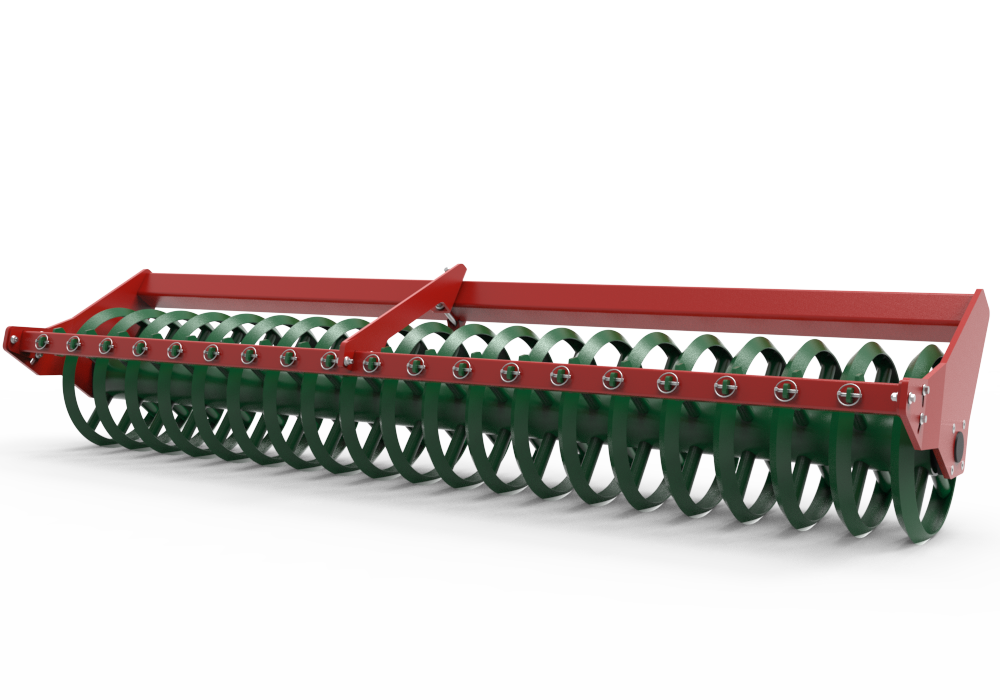

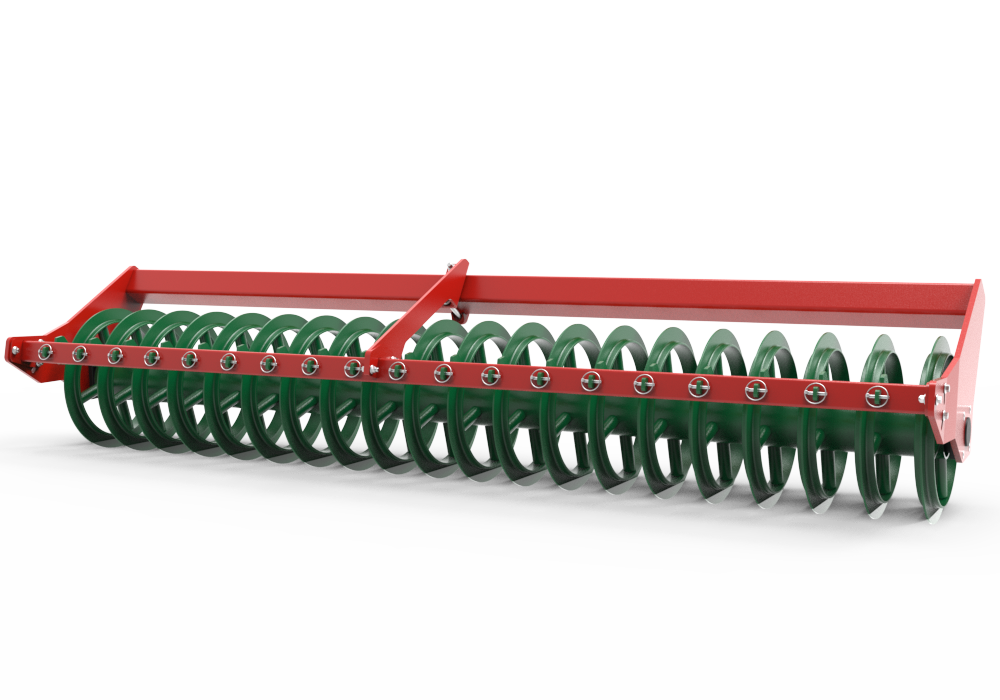

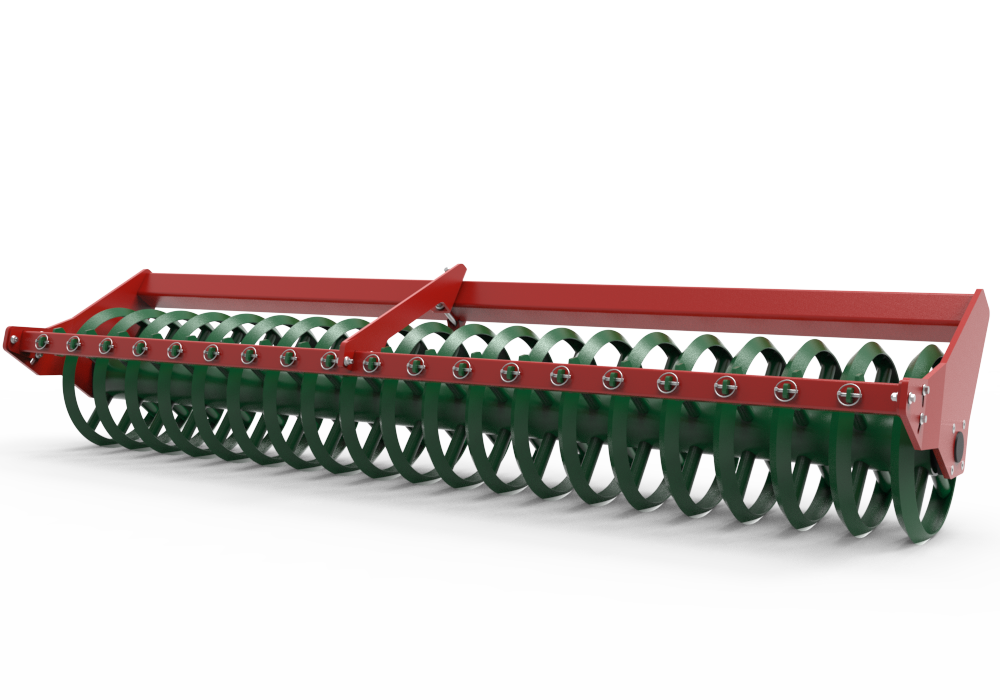

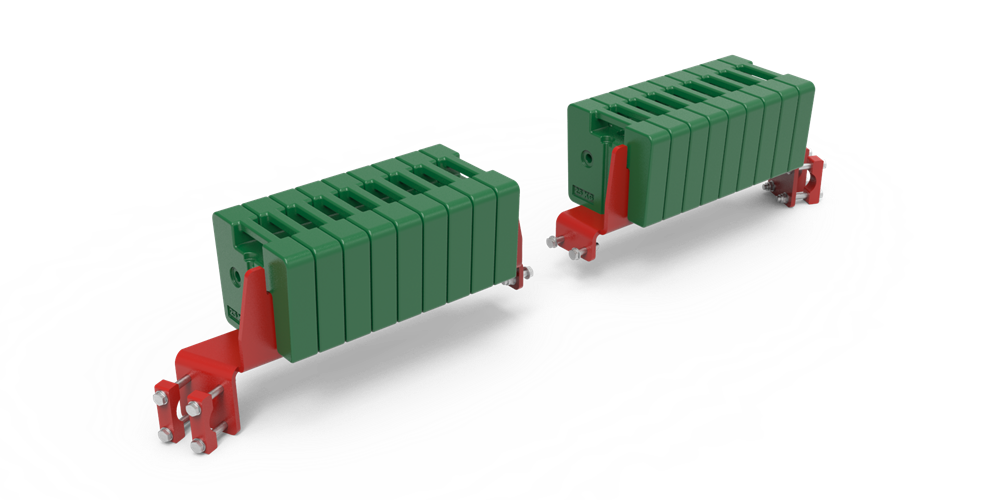

Appropriate selection of the rear roller will allow you to optimize the cultivation for each type of soil and type of cultivated plant.Available shafts have a diameter of 560 or 500 mm

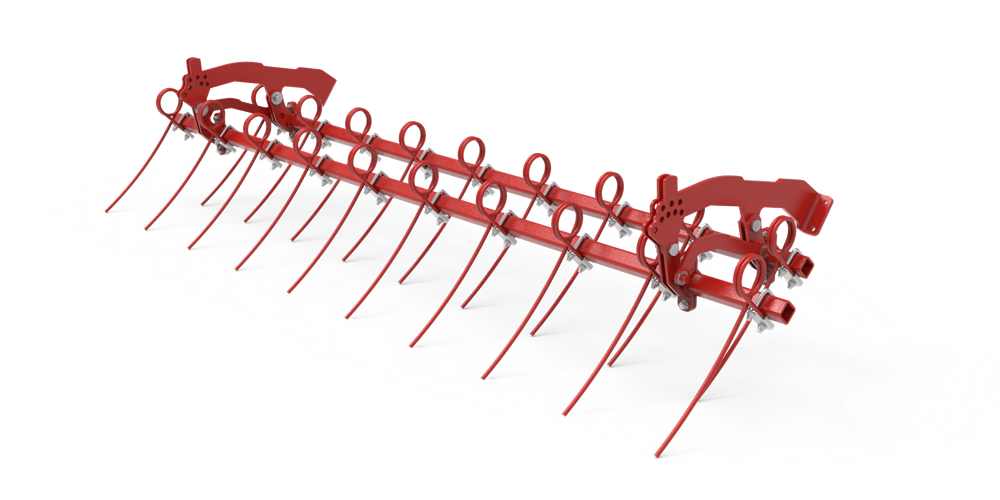

The final working section is a double spring harrow that allows for the even raking of crop residues.

Each plate is mounted on an individual holder with a system of four rubber shock absorbers (35x210 mm). Thanks to the protection, the user can safely operate the disc harrow even in difficult field conditions, while being sure that the machine is solidly protected against possible damage.

Version 2022

for SP230

behind the shaft