Our machines

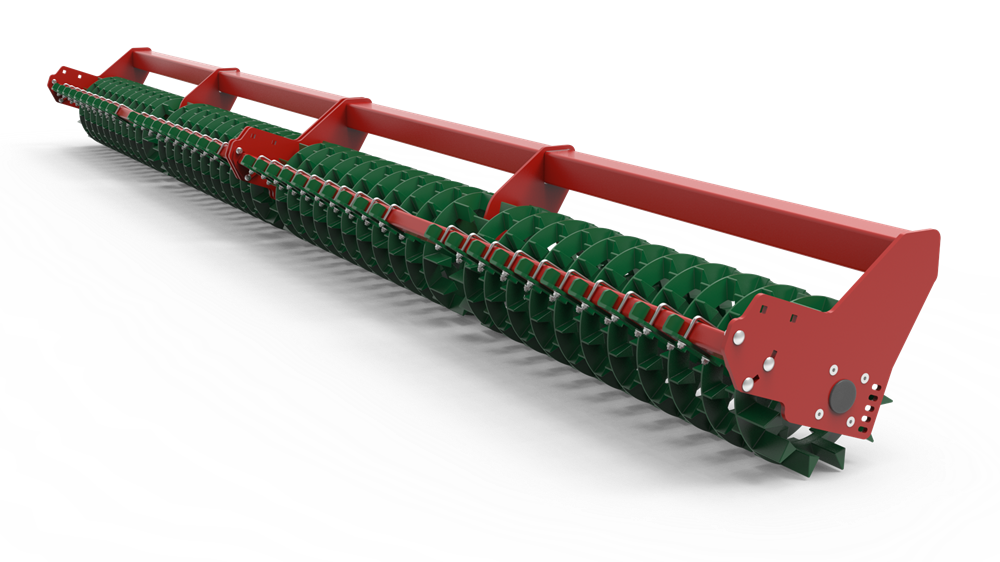

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of tines (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| AUC30 | 3.0 | 1540 | 100 - 140 | 12 | 1.8 - 2.7 | 18 |

| AUC40H | 4.0 | 2250 | 140 - 190 | 16 | 2.6 - 3.8 | 18 |

| AUC50H | 5.0 | 2650 | 175 - 225 | 20 | 3.0 - 4.5 | 18 |

| AUC60H | 6.0 | 3050 | 210 - 260 | 24 | 3.6 - 5.4 | 18 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

m.JPG)

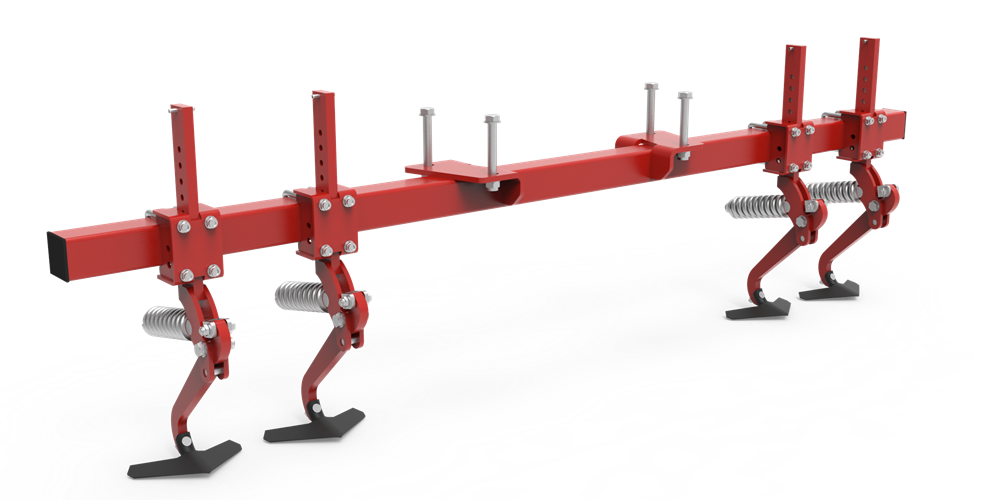

The AUC unit has three models with widths of 4, 5 and 6 meters, with a frame that folds hydraulically for transport. The semi-mounted cultivator is equipped with two tillage sections: the first with two rows of spring tines with goose feet, and the second with four rows of spring tines with a straight coulter. Optionally, the unit can be equipped with a hydraulically adjustable drag made of 80X10 mm springs.

m.JPG)

m.JPG)

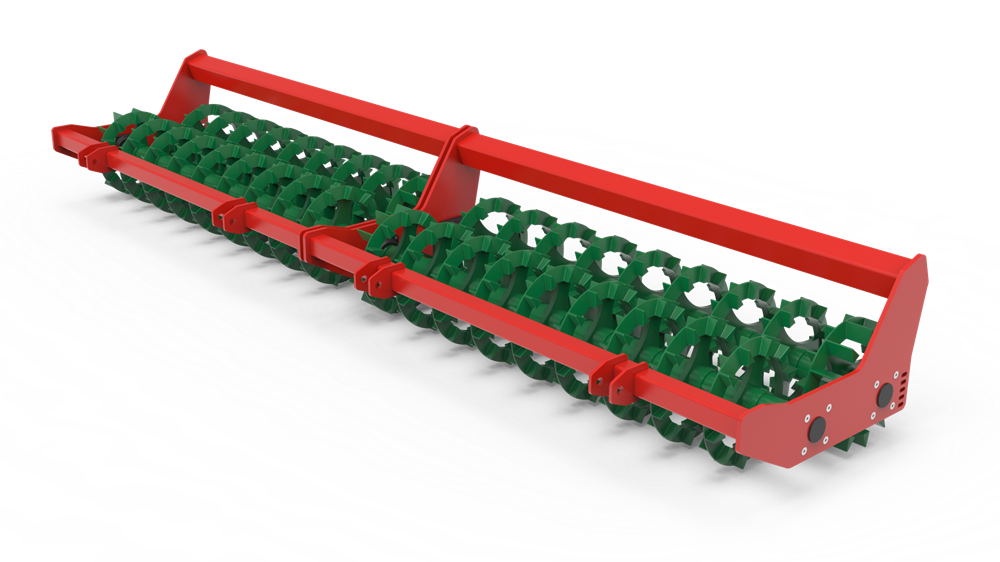

Active screens located at the edge of both sections of the discs restrict the zone where soil is deposited by the outer discs, preventing the formation of ruts at the junctions of passages. In the event of excessive sinking or encountering a significant obstacle, the screen holders are attached to the frame using floating connections, allowing the screens to tilt upward during a collision.

m.JPG)

m.JPG)

The string roller operating behind the first scraper bar is the section responsible for the initial leveling of transverse soil unevenness. The last working section of the machine is also a roller, this time a crosskill or tandem crosskill working between the second and third strips. You will achieve optimal alignment without a doubt!

m.JPG)

m.JPG)