Our machines

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of discs (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| AT25 | 2.5 | 940 | 85 - 115 | 20 | 1.6 - 2.4 | 14 |

| AT27 | 2.7 | 1040 | 90 - 120 | 22 | 1.8 - 2.6 | 14 |

| AT30 | 3.0 | 1200 | 100 - 130 | 24 | 2.0 - 3.0 | 14 |

| AT35 | 3.5 | 1385 | 105 - 145 | 28 | 2.4 - 3.6 | 14 |

| AT40 | 4.0 | 1570 | 110 - 150 | 32 | 2.8 - 4.2 | 14 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

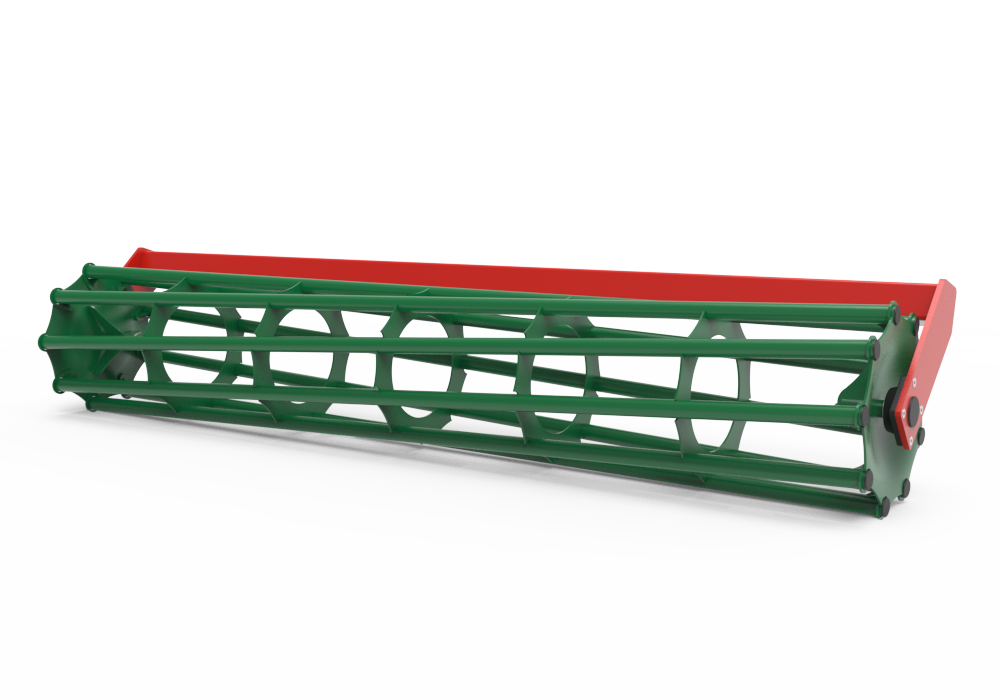

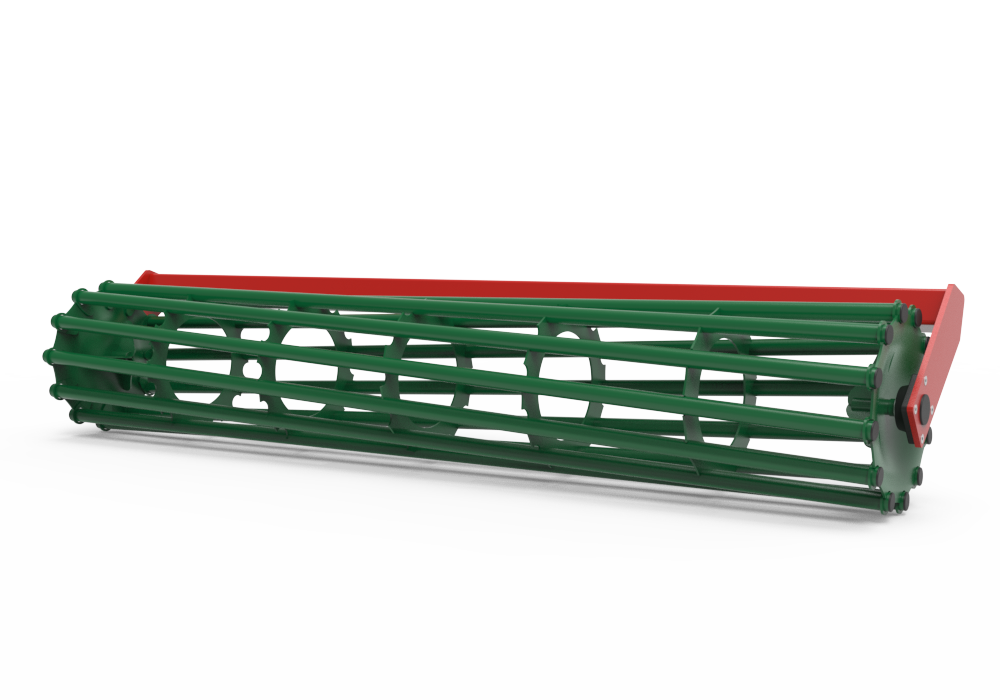

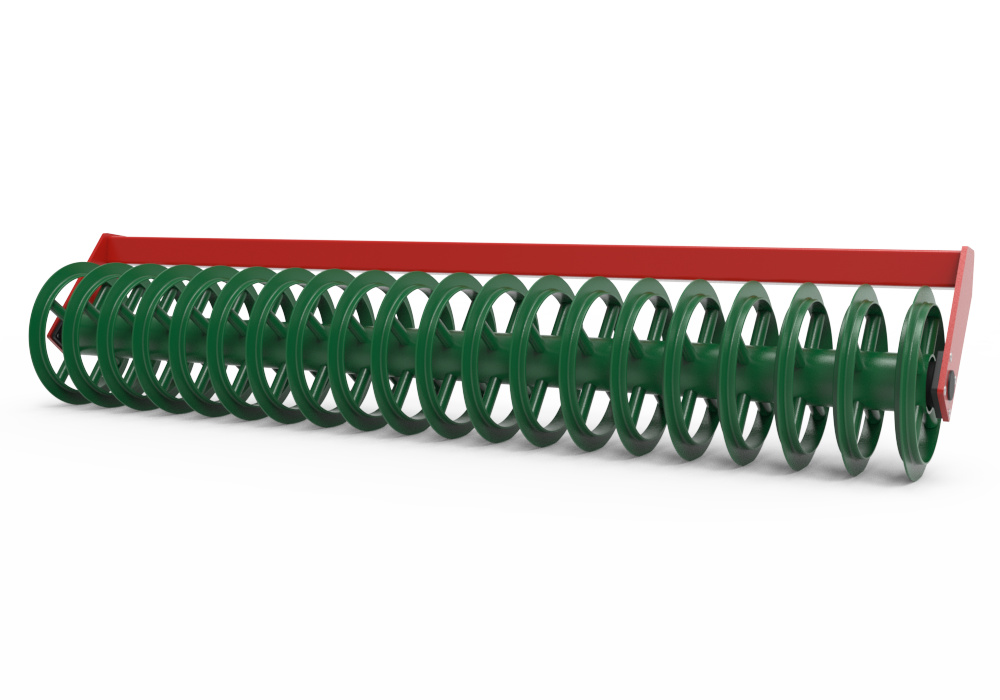

The AT series aggregates are machines that are the realization of the idea of creating a cultivation structure of low weight and compact construction. Thanks to the built-in system, the hydropack can work in conjunction with cereal seed drills to create a combination of seed drills, efficient and easy to use.

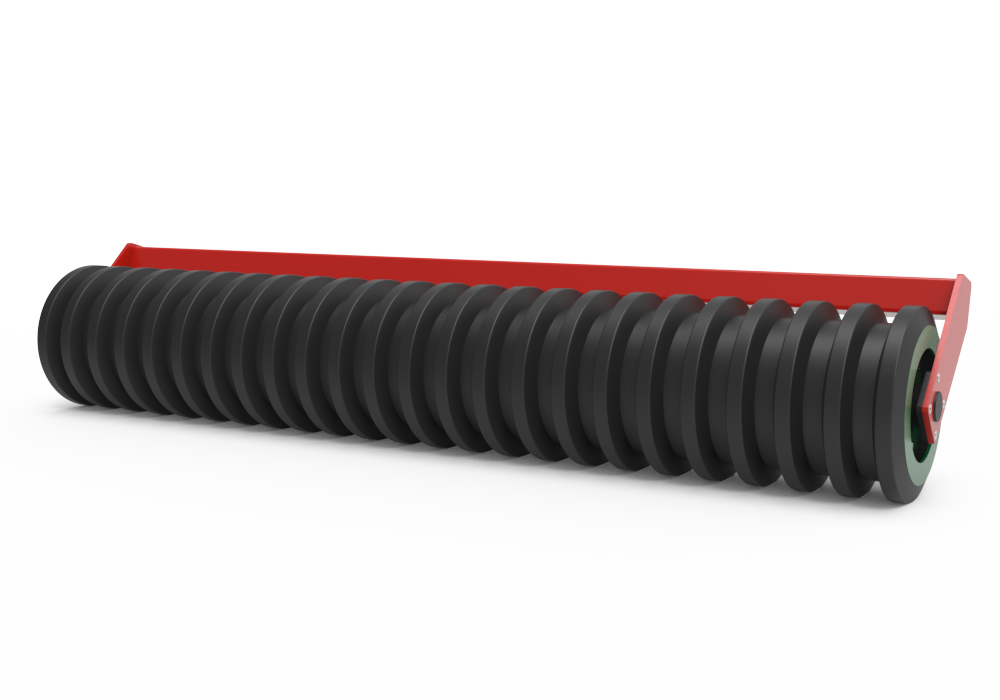

You don't have to start work everyday with time-consuming lubrication. Our disc harrows are standard equipped with maintenance-free hubs, in the heart of which work bearings identical to those used in the automotive industry. The entire system is protected with cartridge sealers, which are most effective in harsh field work.

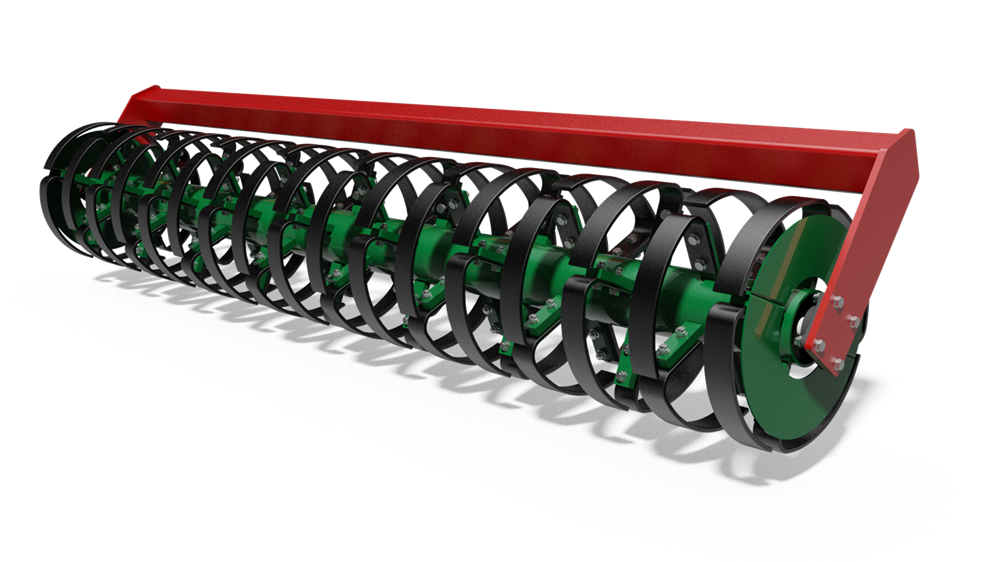

Active screens located on the edge of both disc sections limit the soil deposition zone by the outer discs, preventing rutting at the junction of passages. In the event of excessive depression or a large obstacle, the screen holders are attached to the frame with floating connections, allowing the screens to tilt up during a collision. So you don't have to adjust the screen, it adjusts itself to the conditions. In addition, you can adjust its depth and longitudinal position.

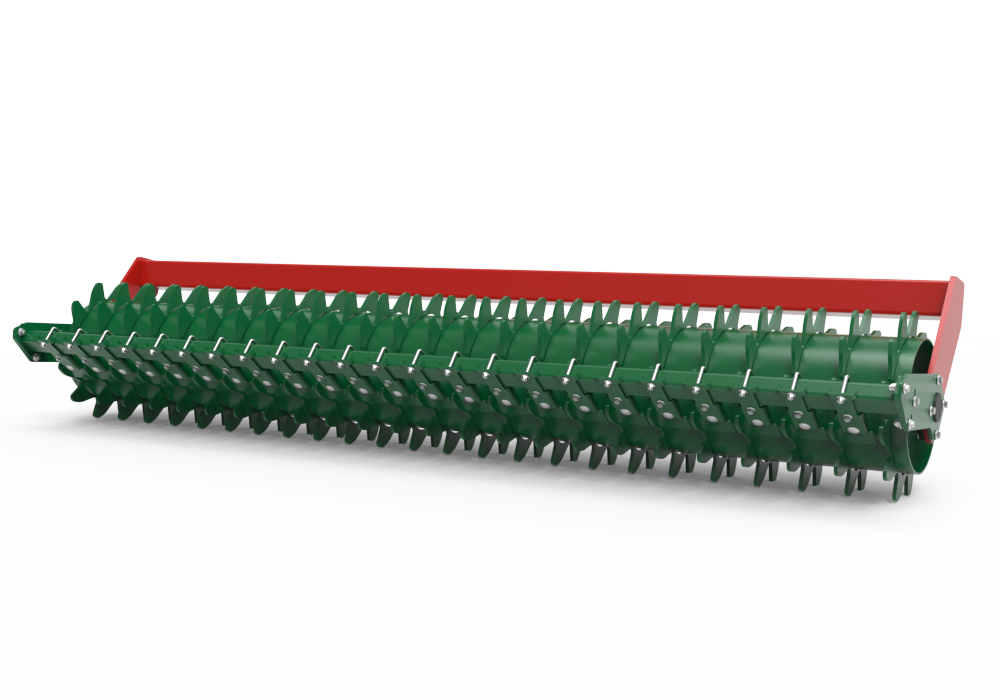

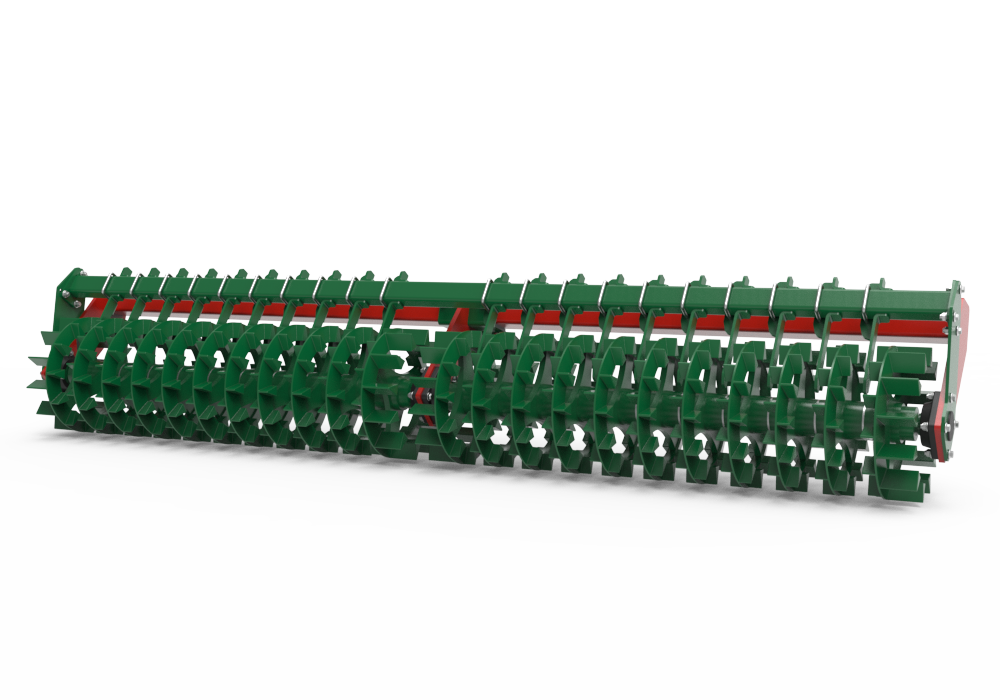

Plates with a diameter of 510 or 560 mm are mounted on individual holders amortized by a system of four rubber elastomers that effectively protect the plates against damage. The shock absorbers also reduce vibrations transmitted to the machine. A suitable grip profile is constructed to prevent blocking between it and the working plate of stones. Work without worry, without breaks.

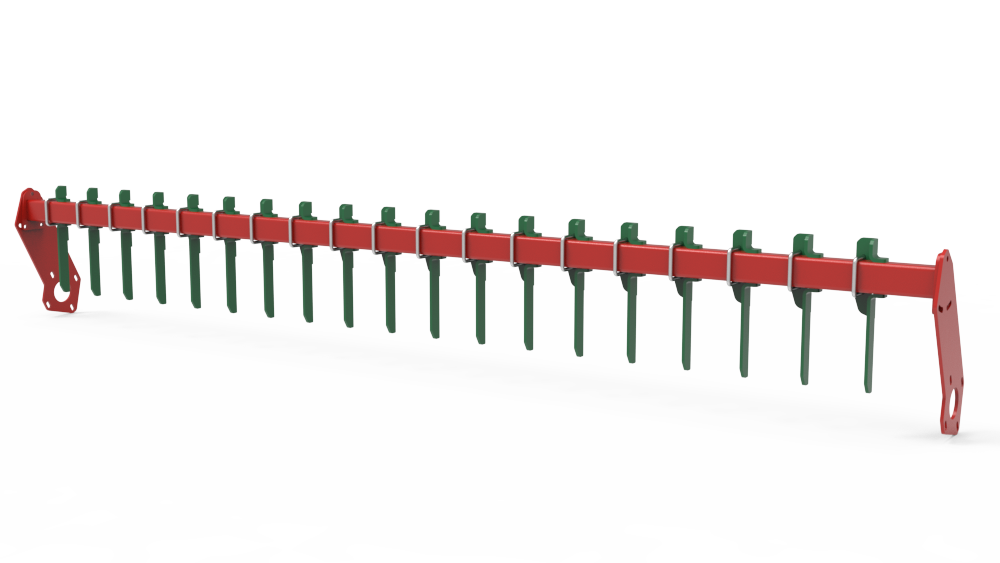

The rake angle and the cutting angle of the discs suitable for high working speeds allow the user to obtain the fullest possible effect of mixing crop residues with the soil with the disc row spacing reduced to 70 cm. It is not the machine that determines job opportunities! You set the limits!

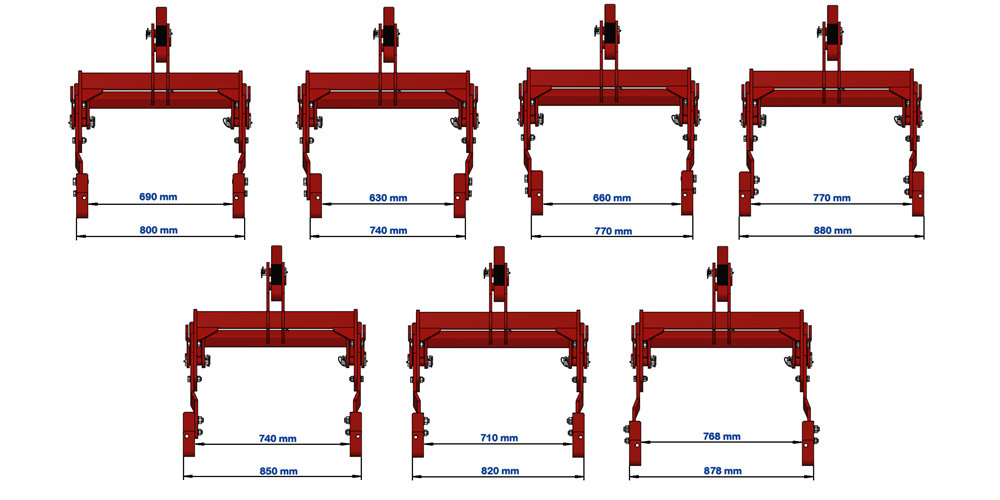

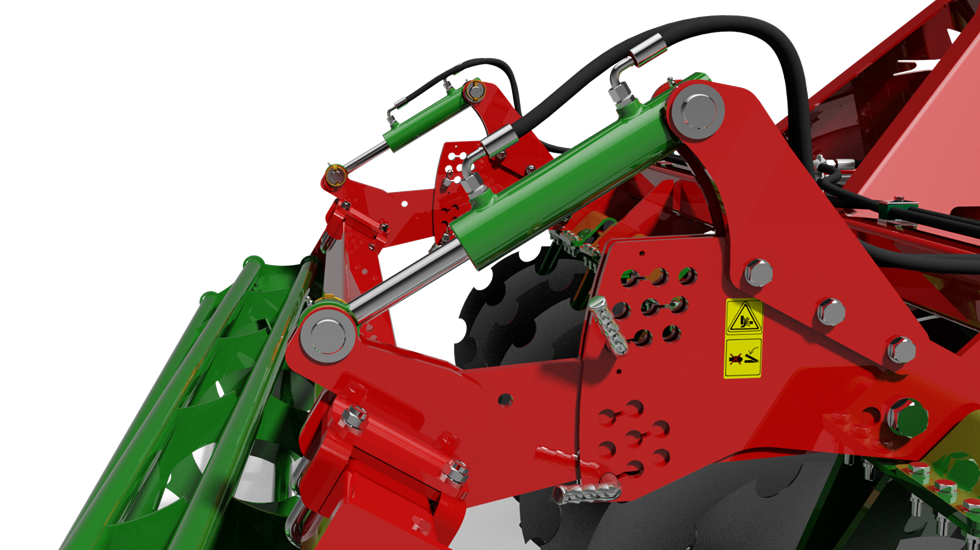

Thanks to the special structure, our hydropack is equipped with the possibility of various configurations of the width of the mounts, so that it can also be adapted to seed drills from other manufacturers.

The system of pins locking the position of the rear shaft arms, thanks to which we adjust the working depth of the machine, can be retrofitted with a system of supporting hydraulic cylinders at any time. In this version, the working depth of the machine is conveniently controlled by controlling the hydraulics from the tractor cabin.