Our machines

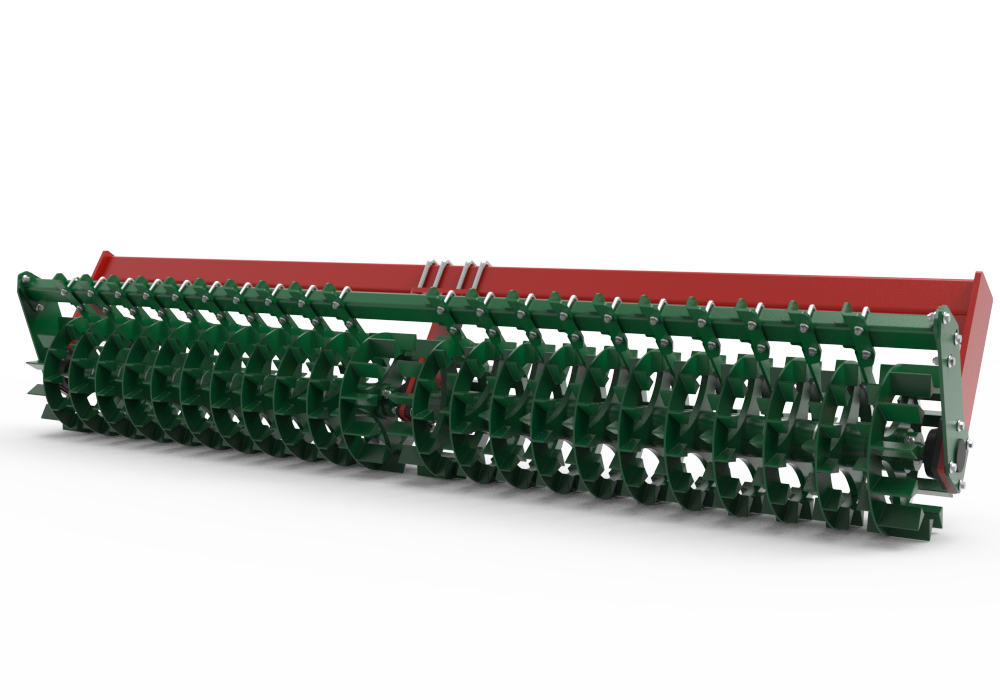

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| BT15 | 1.50 | 700 | 50 | 12 | 1.0 - 1.5 | 14 |

| BT17 | 1.75 | 780 | 60 | 14 | 1.1 - 1.7 | 14 |

| BT20 | 2.00 | 825 | 70 | 16 | 1.3 - 2.0 | 14 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

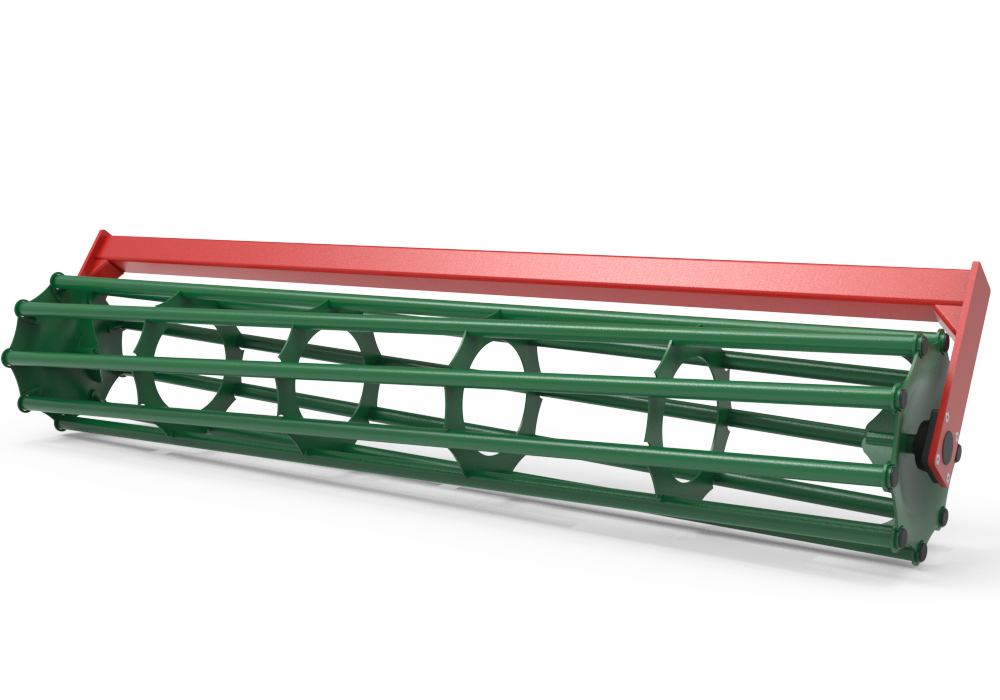

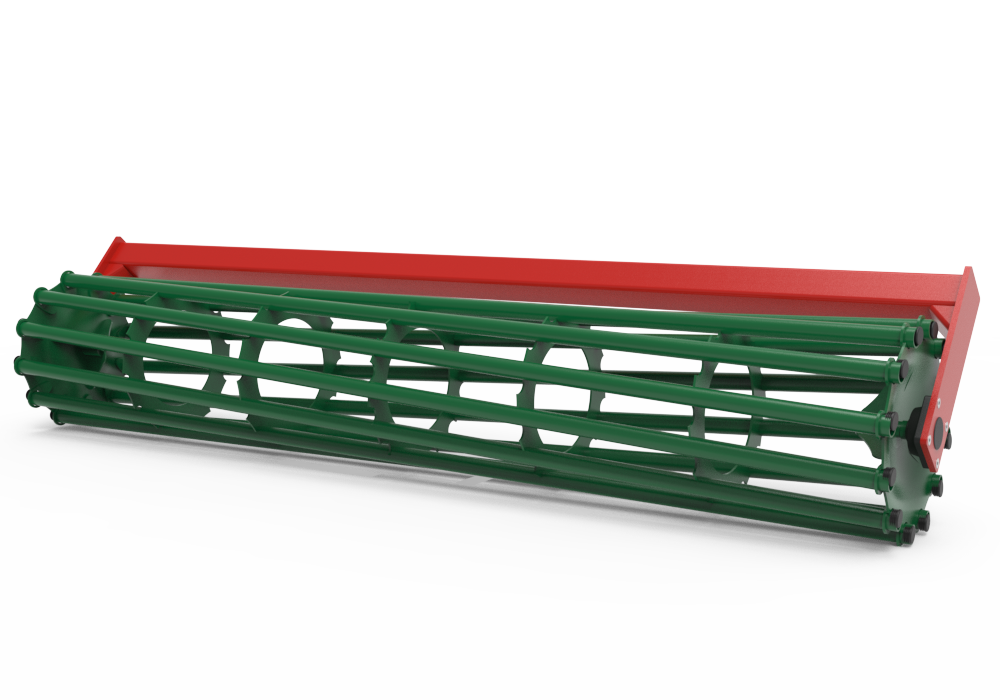

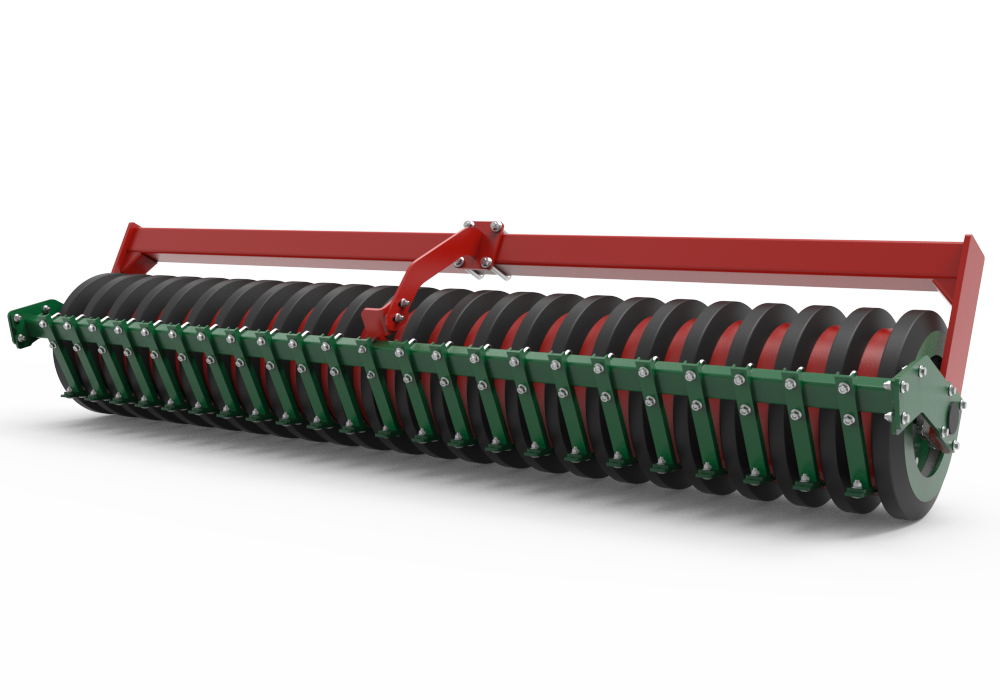

BT 1.5 - 2.0 m was designed for work in vineyards and orchards. This harrow is the smallest machine produced by us. Its size and weight allow it to be used in places inaccessible to larger machines. In BT 1.5 - 2.0 m we used solutions that are the same as in our other harrows, thanks to which we have kept the efficiency and durability, which are the determinant of the quality of our machines.

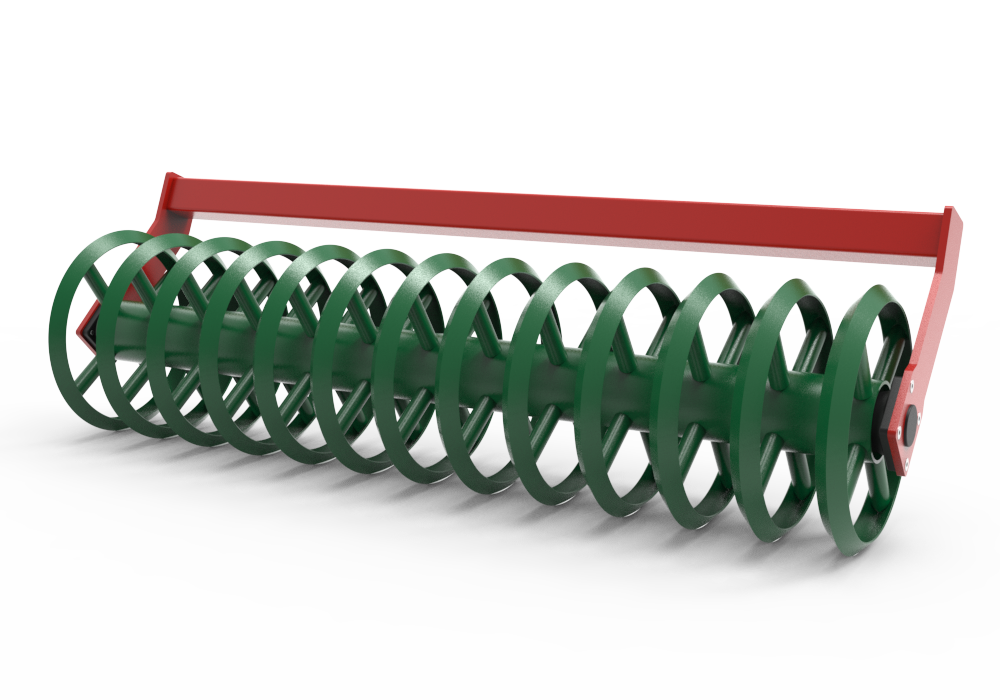

Our disc harrows are standard equipped with maintenance-free hubs, in the heart of which work bearings identical to those used in the automotive industry. The entire system is protected with cartridge sealers, which are most effective in harsh field work.

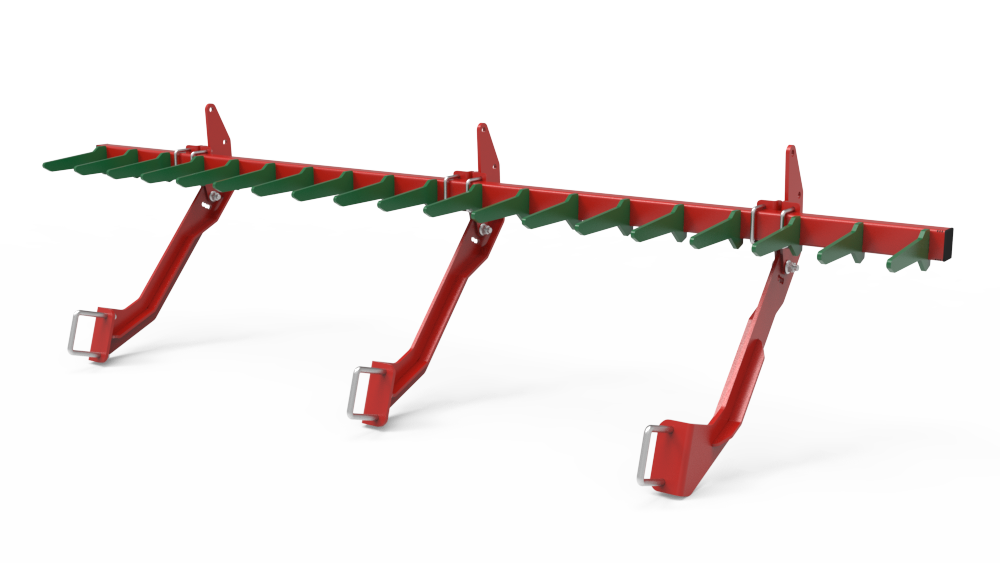

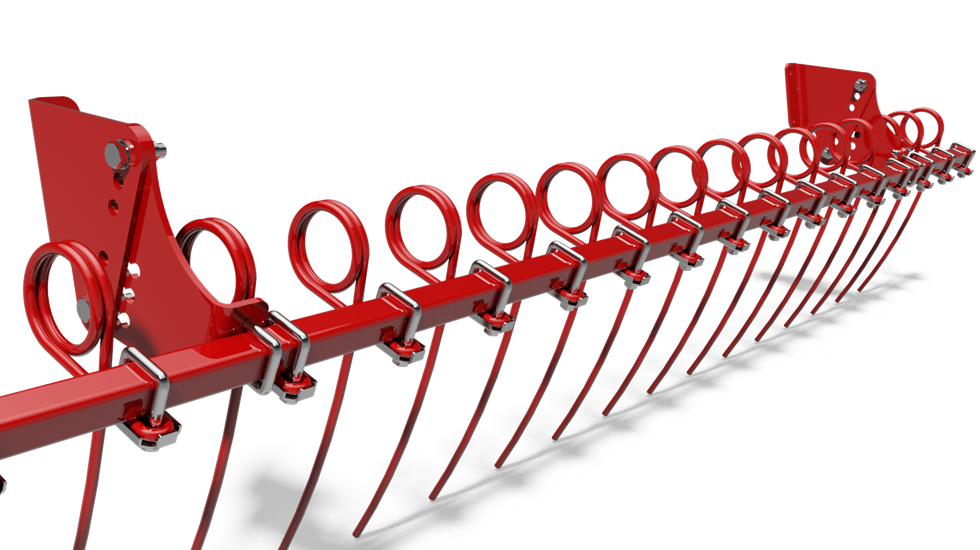

Active screens located on the edge of both disc sections limit the soil deposition zone by the outer discs, preventing rutting at the junction of passages. In the event of excessive depression or a large obstacle, the screen holders are attached to the frame with floating connections, allowing the screens to tilt up during a collision.So you don't have to adjust the screen, it adjusts itself to the conditions. In addition, you can adjust its depth and longitudinal position.

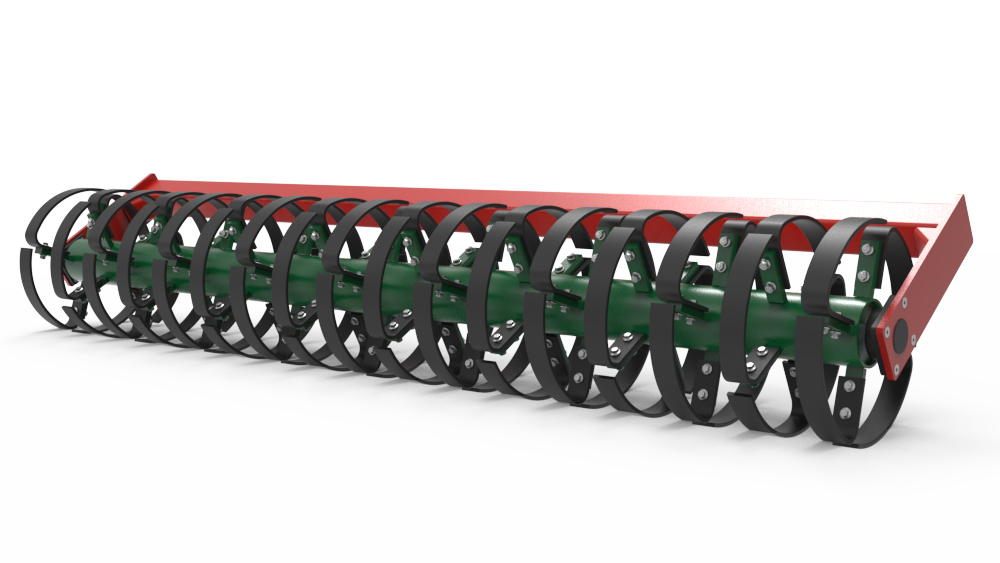

Each plate is mounted on an individual holder in a system of four rubber shock absorbers. They effectively protect the plates against damage. The shock absorbers also reduce vibrations transmitted to the machine. Work without worry, without breaks.

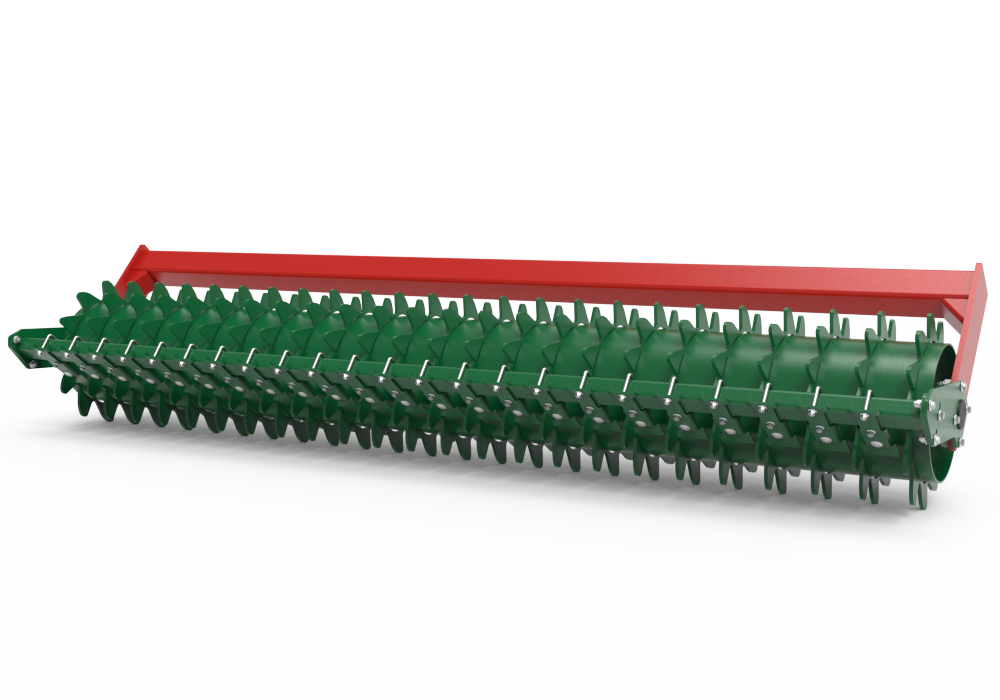

The rake angle and the cutting angle of the discs suitable for high working speeds allow the user to obtain the fullest possible effect of mixing crop residues with the soil with the disc row spacing increased to 78 cm. It is not the machine that determines job opportunities! You set the limits!

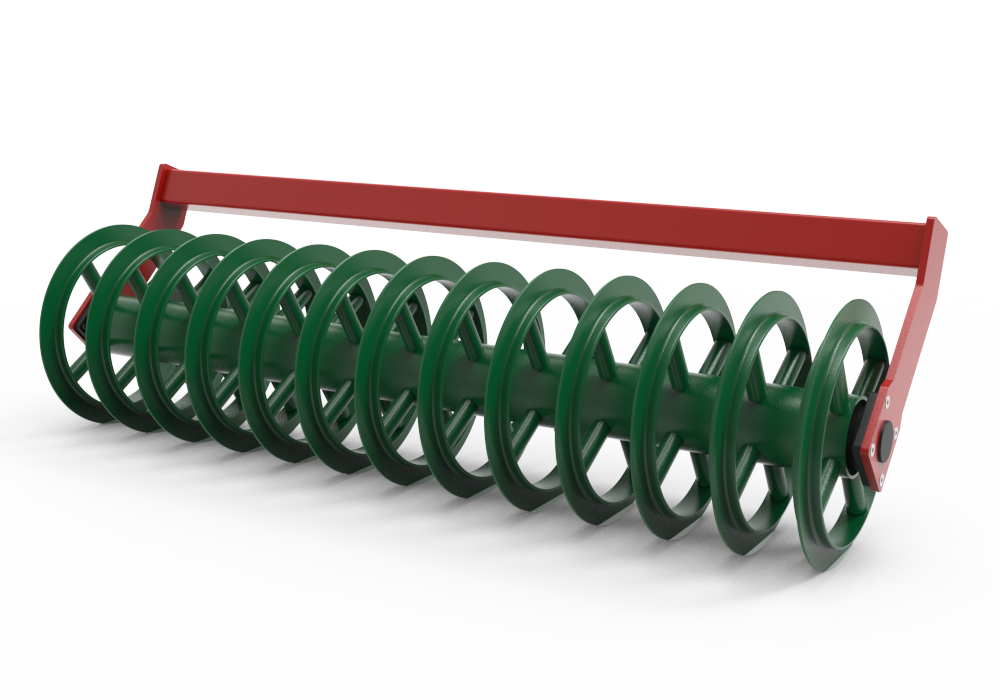

The best effect of crushing the soil and its leveling on the surface is achieved by the work of the comb. After one working pass, the soil is prepared for sowing.