Our machines

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) (cm) |

|---|---|---|---|---|---|---|

| PO3 | 1.05 - 1.50 | 1250 | 80 - 115 | 3 | 0.8 - 1.3 | 30 |

| PO4 | 1.40 - 2.00 | 1500 | 115 - 140 | 4 or 3+1 | 1.0 - 1.7 | 30 |

| PO5 | 1.75 - 2.50 | 1740 | 130 - 180 | 5 or 4+1 | 1.2 - 2.0 | 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

Reliability and ease of use enclosed in a solid construction. Our plows combine these features and will certainly meet your requirements. An adequate clearance under the frame of 76 cm and a body spacing of 100 cm guarantee covering even a significant amount of crop residues and catch crops. The use of quality steel allowed for a very durable construction with the lowest total weight of the machine in its class. The frame (profile 140 x 140 mm) made of steel with improved parameters, thermally improved, ensures that the plow will cope even in difficult conditions. Our experience, opinions of satisfied customers, and continuous tests allow us to create new solutions, which results in the next generation of rotary plows.

Hydraulic body protection for heavy and stony soils. Each body reacts independently to obstacles, and the actuator allows you to minimize the forces arising during a collision and to quickly return the body to the precisely set working position. The unique technology of making articulated points located on the connection of each body with the pocket allows you to lead plowing in almost any conditions without stress. Each body maintains its position until the share blade exceeds the force set on the central unit. With such a high force, the bodies are released. We can set this value taking into account field conditions. One plow, and "flexible" enough to find in all conditions. The load that must be applied to the body for the hydraulic protection to operate is max 900 kg (120 bar).

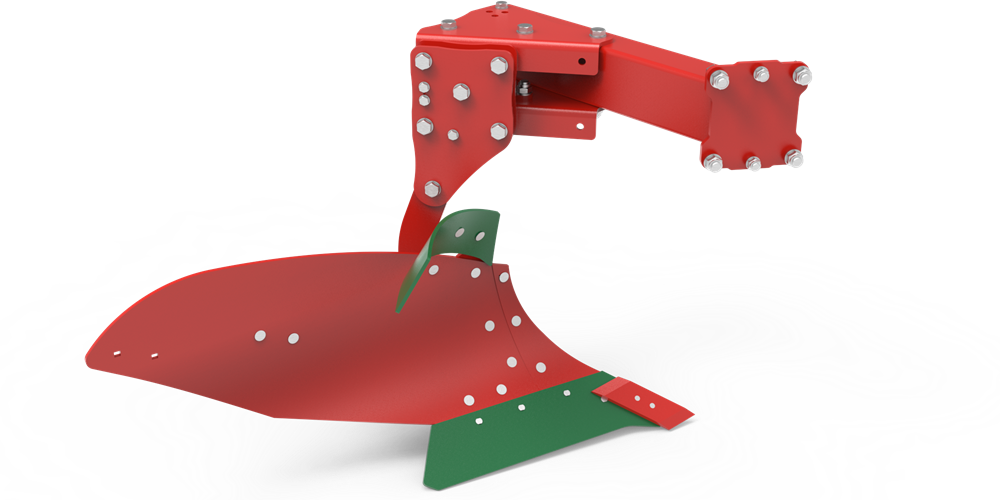

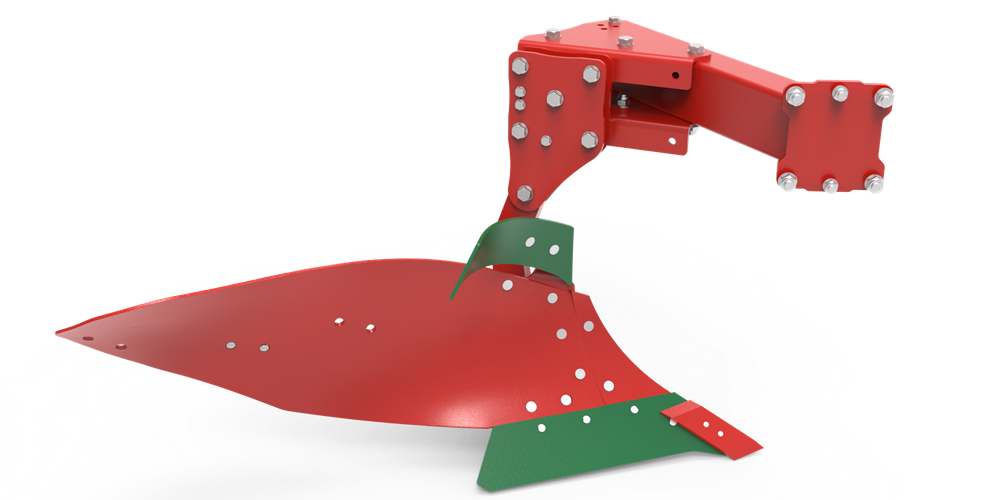

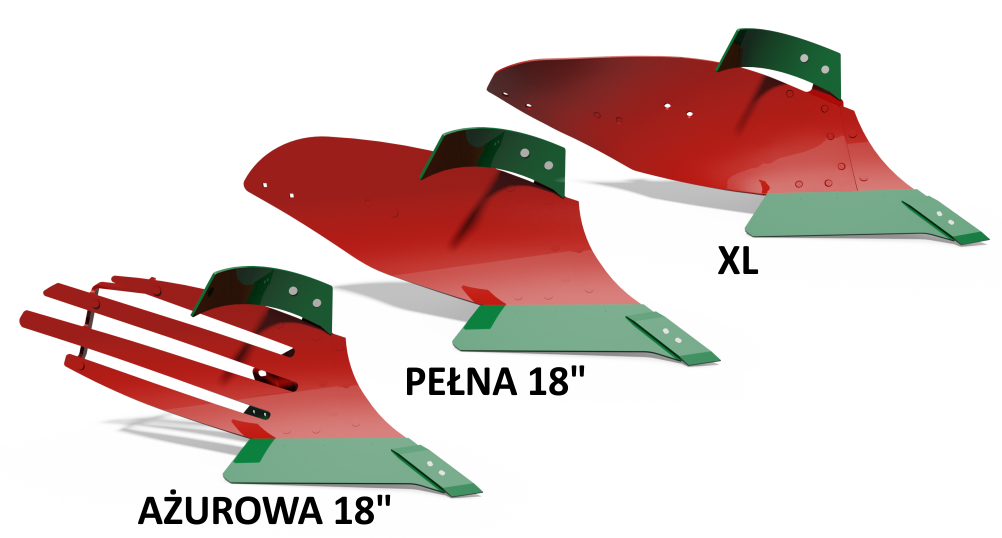

Our bodies work even at speeds of up to 10 km / h. The work of each body gives the effect of even furrow edges with full inversion of each furrow, even with a large amount of organic residues. Much of this is due to the cylindrical-screw type depot, which puts little resistance additionally significantly reducing fuel consumption. The bodies are also great at crushing larger lumps of soil. As standard, shear bars mounted on each body work on soils with a large amount of crop residues, without reducing the clearance between the bodies, as in the case of using skimmers, and thus do not cause the risk of clogging the machine. You will certainly appreciate the simple screw regulation of the depot and the angle of attack of the whole body, especially when you set low fuel consumption as a determinant of effective work.

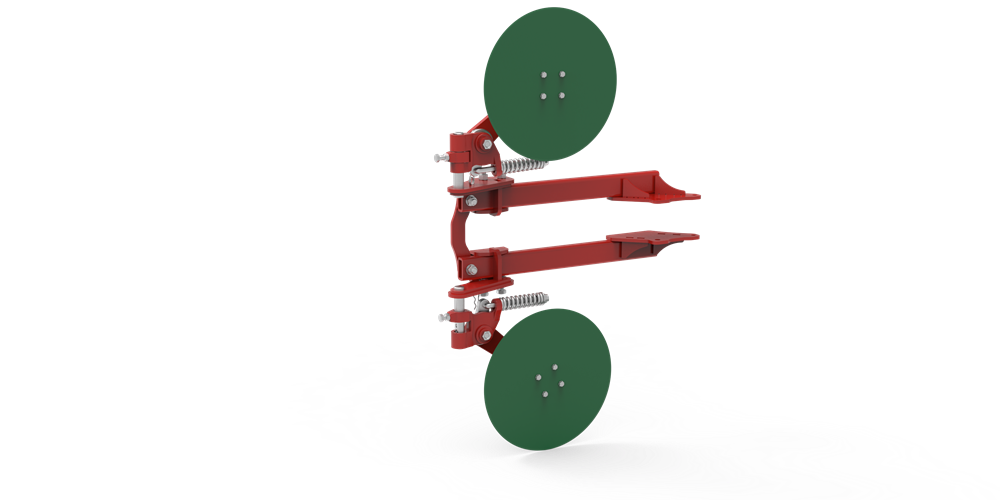

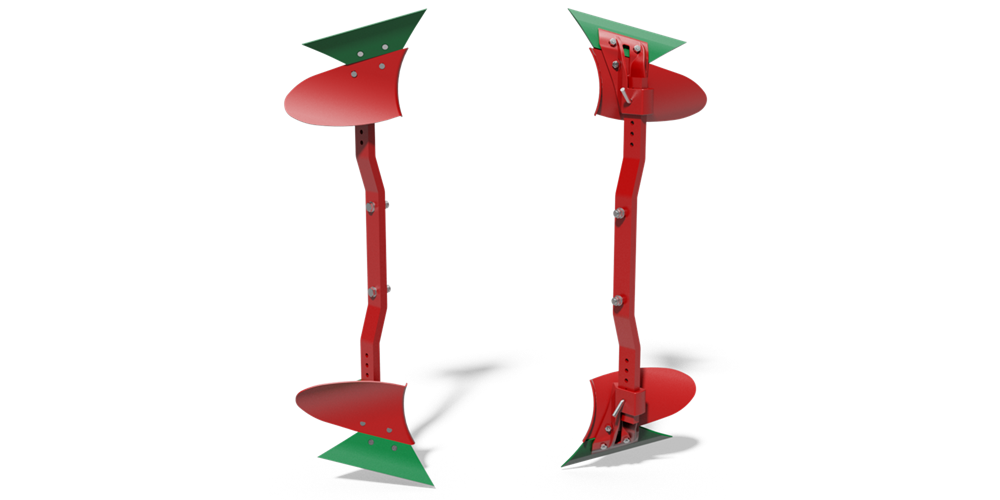

Corrugated plates with a diameter of 500 mm, both for models with screw and spring protection, significantly improve the visual effect of the plow's work. By cutting the furrow from the furrow bottom, the cutting plates ensure the most accurate reversal of the furrow, leaving a clean furrow with smooth walls. Additionally, as a result of the cutting action, there is an increased effect of covering residue from harvesting. Like every working element, cutting blades are protected against damage in challenging soil conditions. In this case, the safety feature is provided by a spring with adjustable pressure force. Meanwhile, achieving the optimal working position of the cutting plate is assisted by toothed adjusting blocks.

During plowing of long-fallowed fields, meadows, or pastures, extension strips mounted on the moldboards prove to be extremely useful.

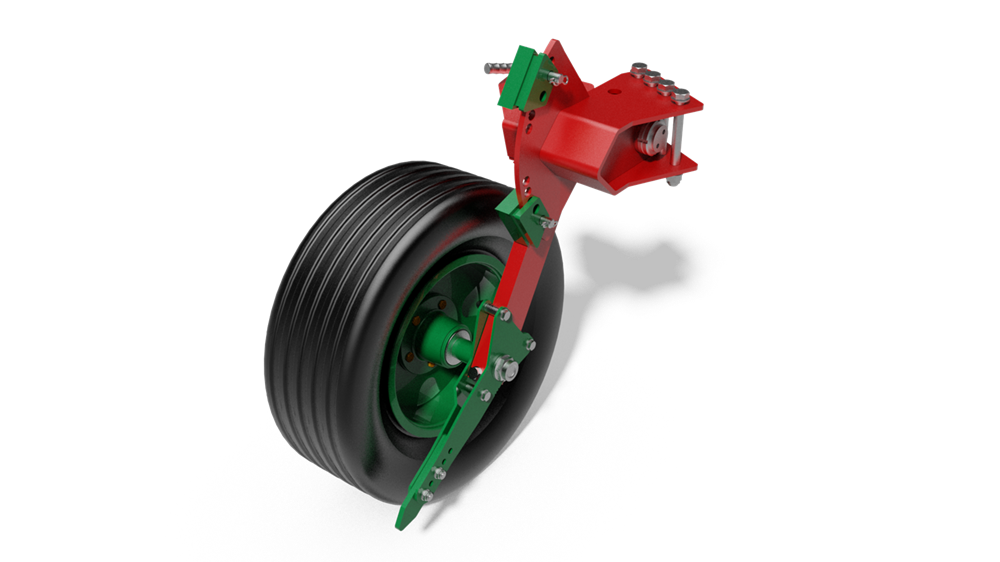

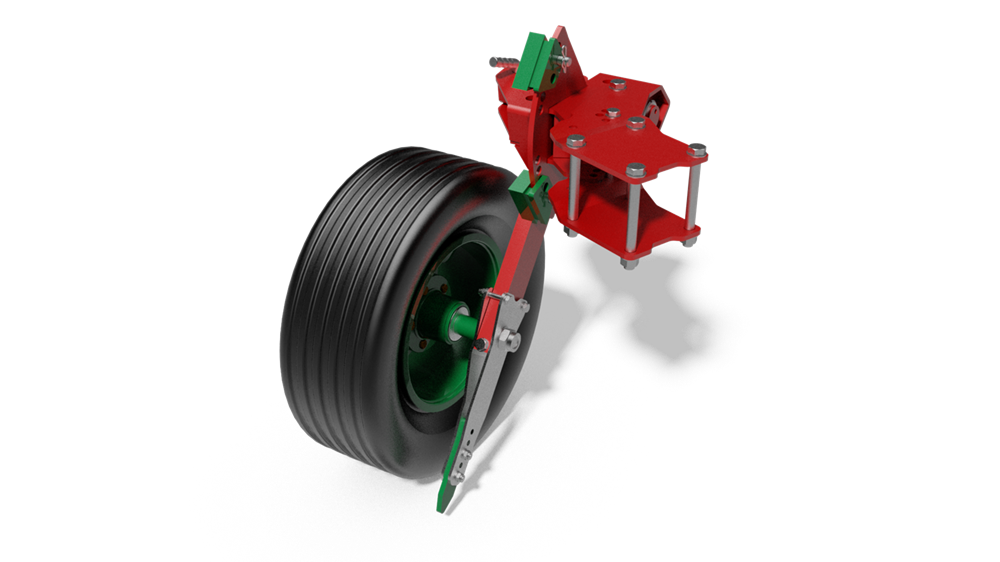

As part of a single pass, we perform plowing and secondary soil compaction, breaking down large soil clods and leaving the field well-prepared for subsequent operations. The shaft arm is adjustable, and the engagement/disengagement of the shaft occurs automatically.

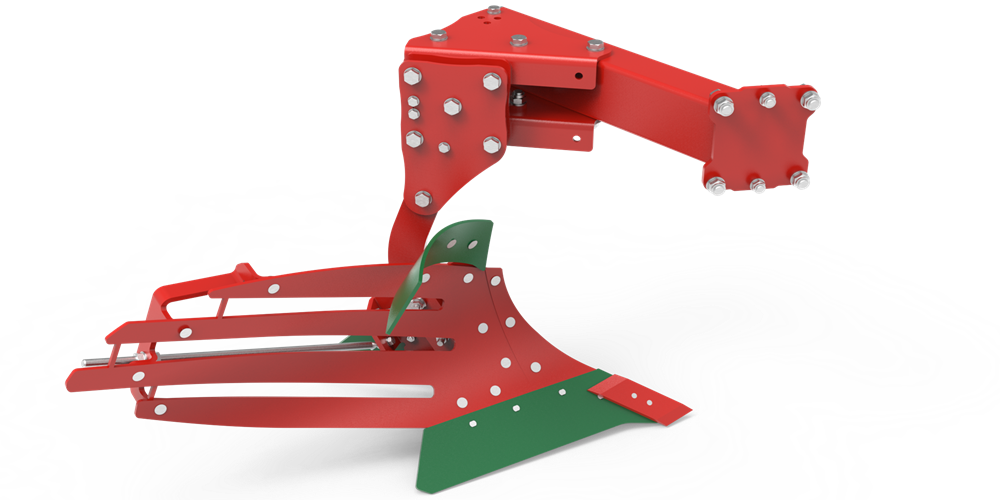

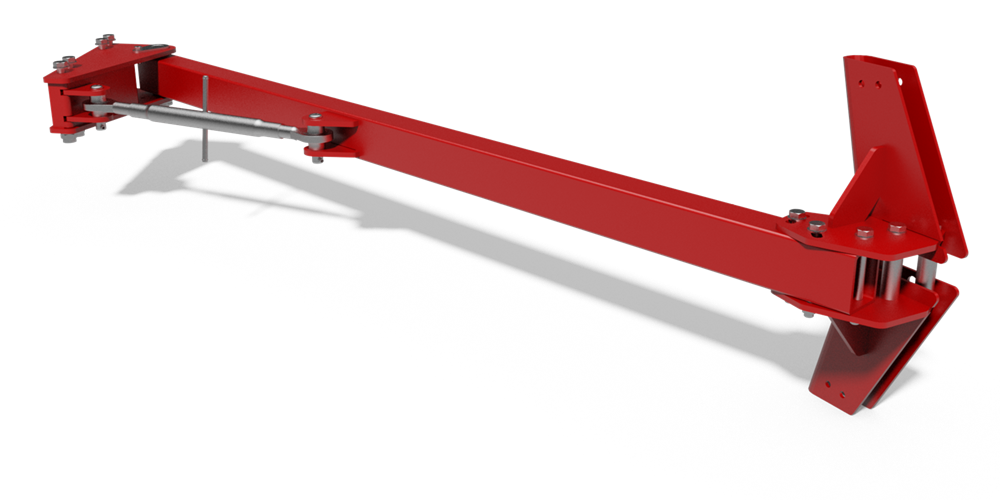

To achieve the most thorough mixing with the soil and cover crop residues, the plow can be equipped with a set of front extension bodies. The optimal working position can be adjusted through a multi-stage incremental adjustment. The position of the extension bodies is easily changed using an adjusting screw, which locks the position of the extension body. Each extension body is equipped with a universal and commonly used overload protection in the form of a breakaway bolt. Each individual extension body handle is mounted to the pocket of the main body, ensuring that the working geometry of the extension body is identical to the characteristics of the body on which it is mounted. Extension bodies work particularly well in corn stubble fields. When the user decides that satisfactory results are achieved using cutting strips, they can quickly remove the extension bodies and return to the previous configuration.