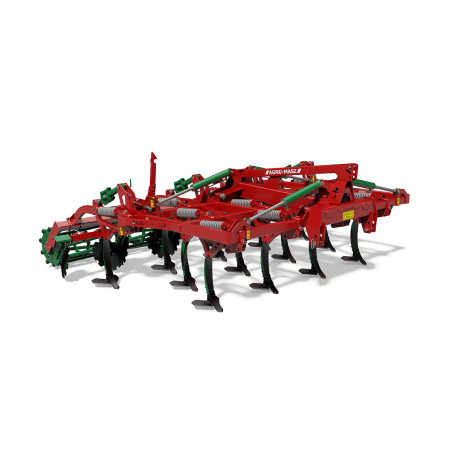

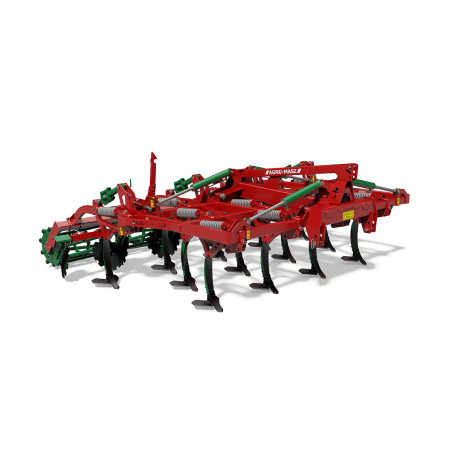

Our machines

| Model | Width (m) | Weight (kg) * | Power demand (HP) | No. of tines (pcs) | No. of discs (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|---|

| RUNNER25 | 2.5 | 1550 | 90 -110 | 7 | 6 | 2 | 35 |

| RUNNER30 | 3.0 | 1850 | 110 - 140 | 10 | 8 | 2.4 | 35 |

| RUNNER35 | 3.5 | 2150 | 150 - 210 | 12 | 9 | 2.8 | 35 |

| RUNNER40H | 4.0 | 2600 | 190 - 250 | 13 | 10 | 3.2 | 35 |

| RUNNER50H | 5.0 | 3000 | 250 - 300 | 16 | 12 | 4.0 | 35 |

*The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

No-plough farming is not only modern technology, but also a step towards sustainable agriculture. By minimizing the negative impact on the environment, saving time and energy, as well as improving the soil structure, this method is becoming more and more popular among farmers looking for innovative and ecological solutions.

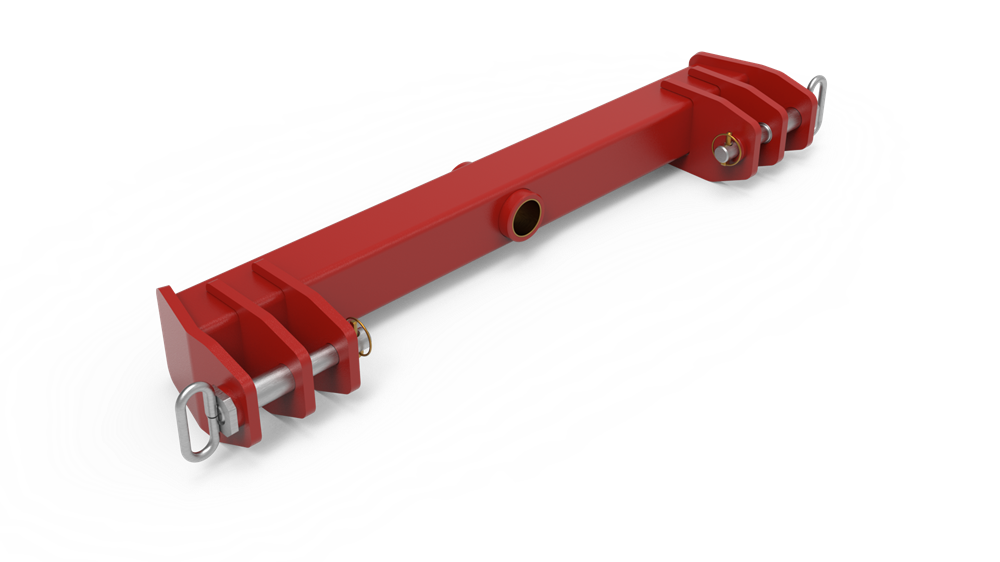

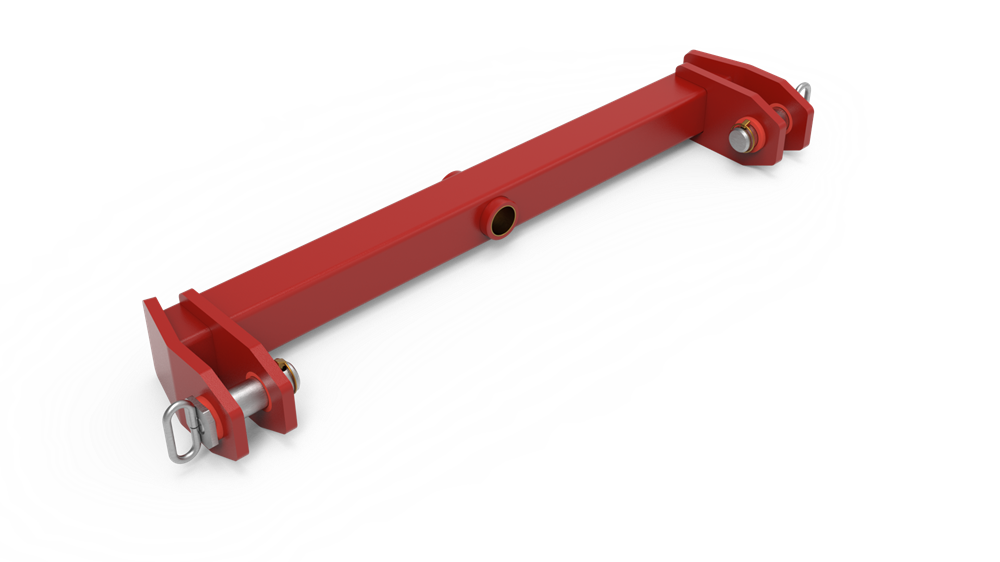

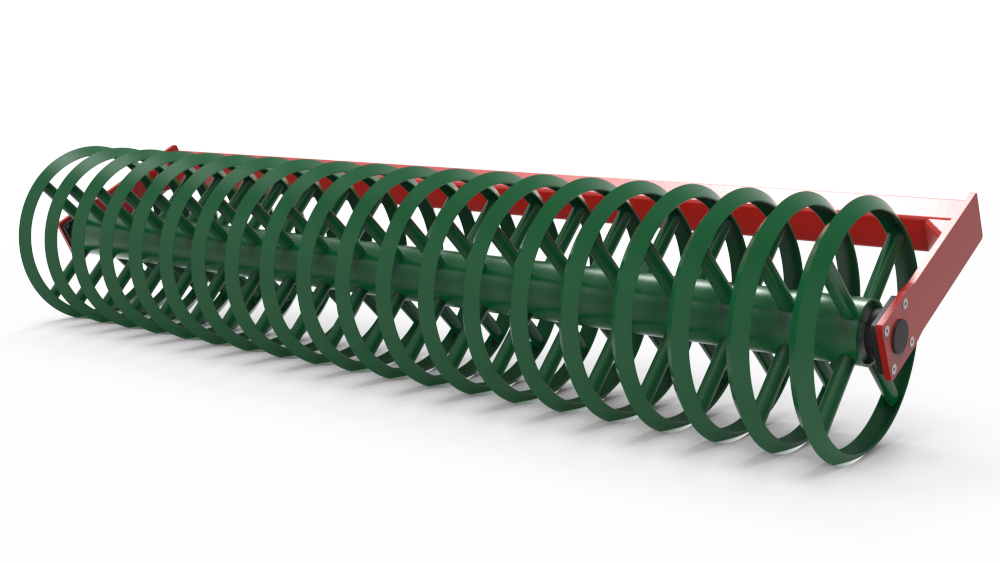

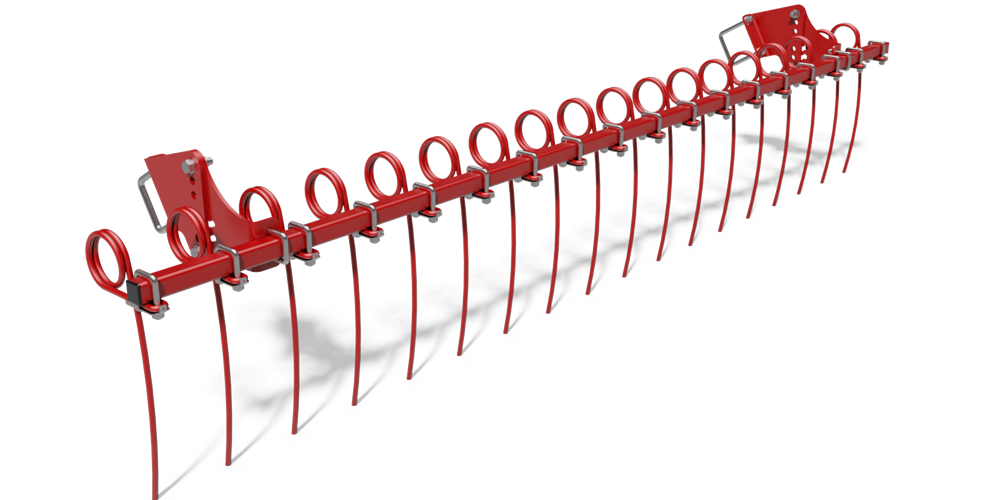

The combination of claws in three sections with two-sided blades and a long mouldboard tuned at the right angle to the ground will allow even and intense mixing of crop residues. Having the opportunity to work also after removing the plowshares, we achieve greater working depths. Thanks to the right combination of distances between the beams and ground clearance you will get excellent results in all conditions.

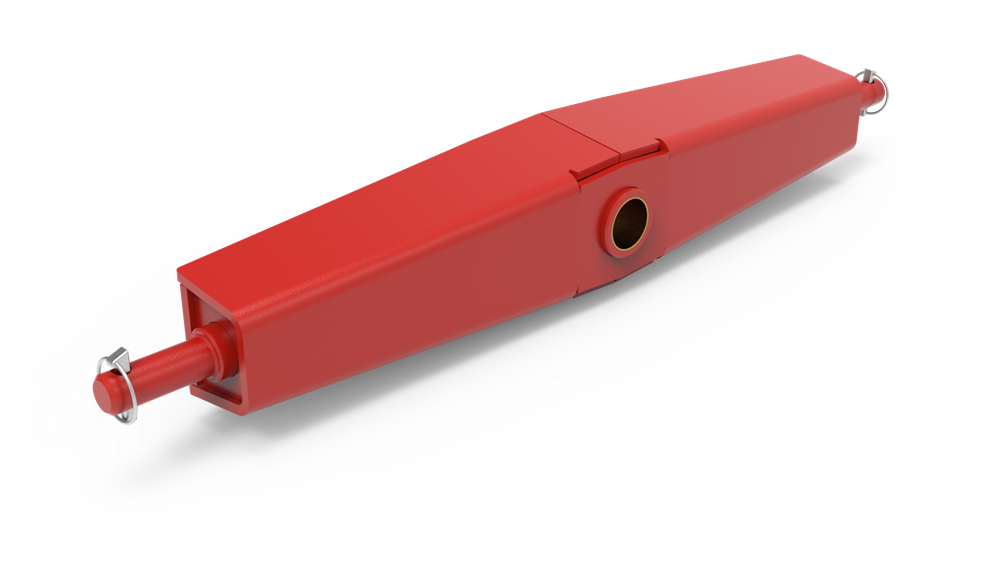

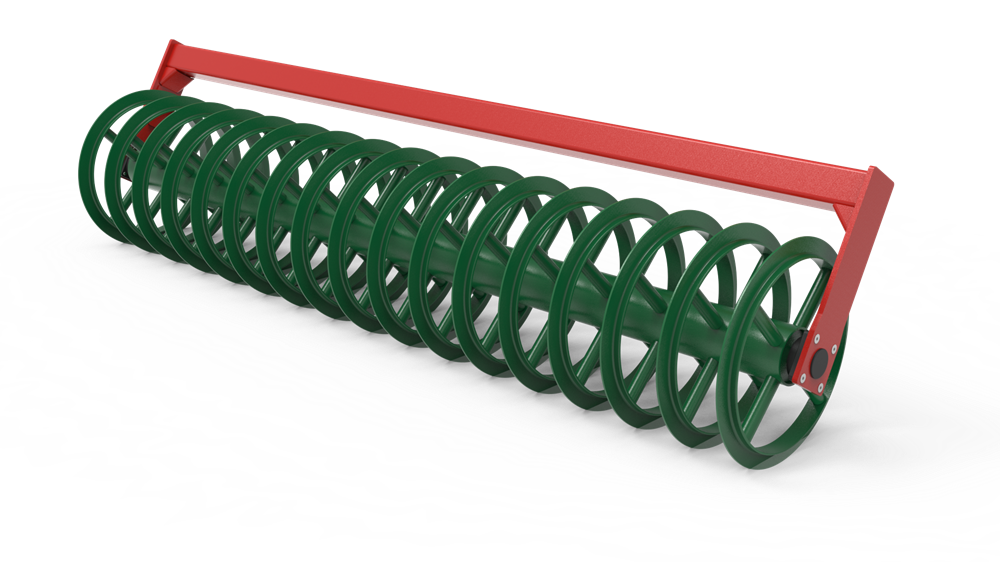

Non-stop. These words include the whole philosophy based on the efficient protection of working elements combined with comfortable operation that does not require frequent operator intervention. For each type of soil, in conditions of non-stony or slightly stony fields, the most effective solution is the double spring system we use to protect each claw.

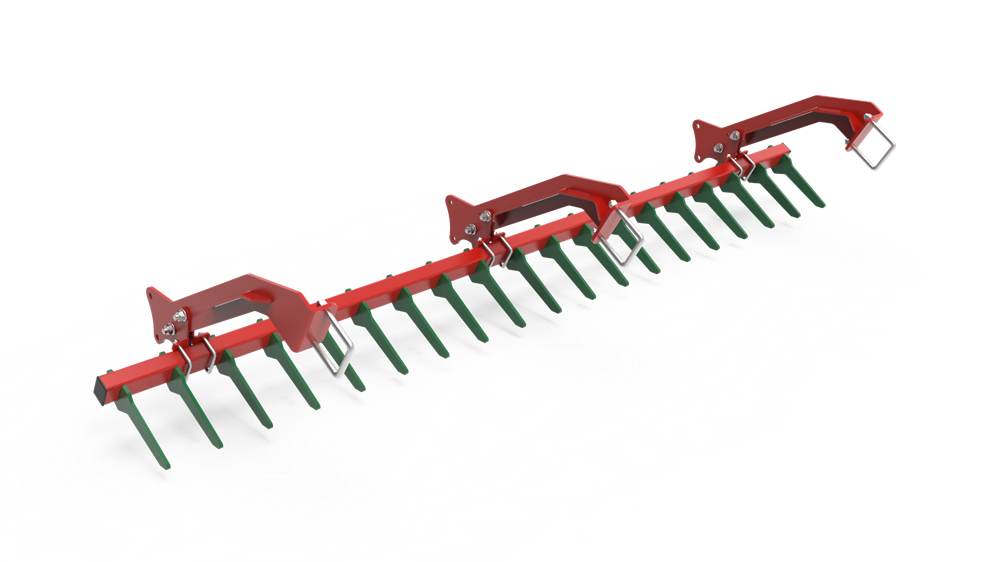

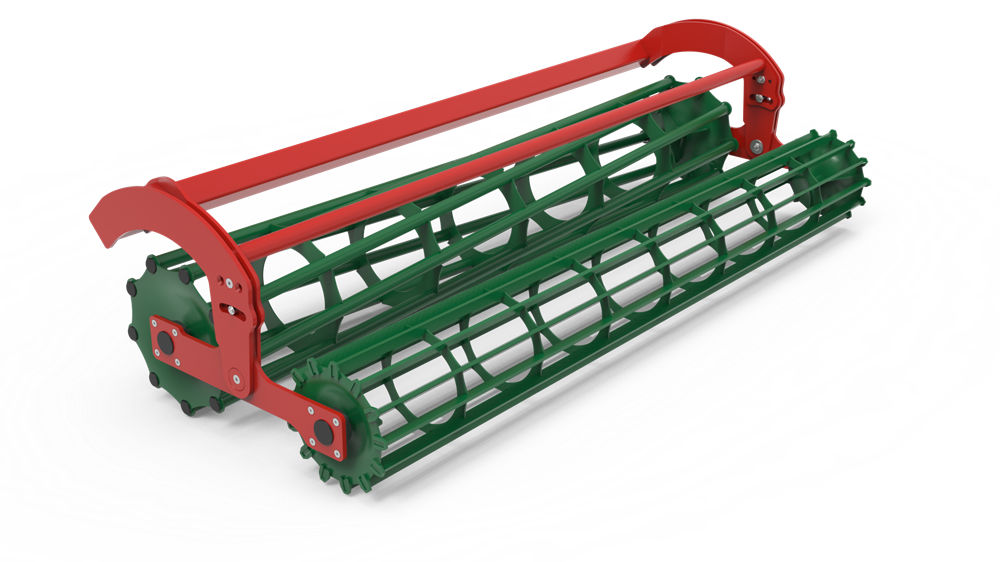

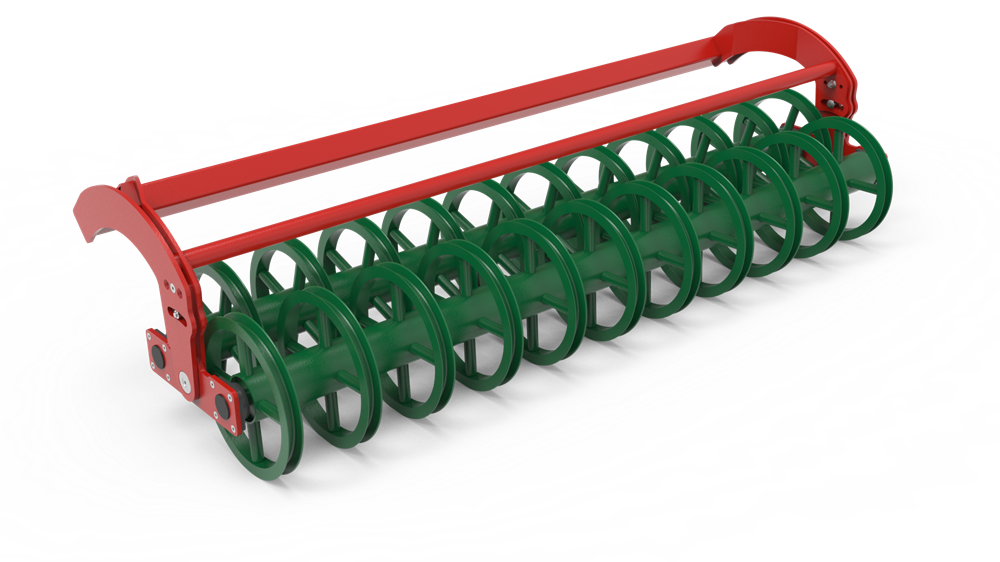

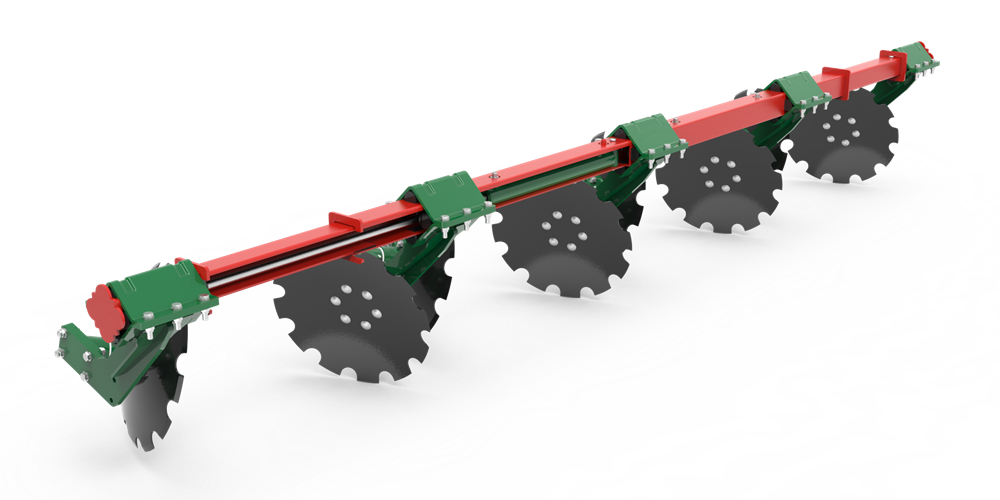

The effect of better mixing and alignment of the cultivated belt is possible thanks to the work of toothed discs stacked in opposite directions and mounted on the arms secured with elastomers.