Our machines

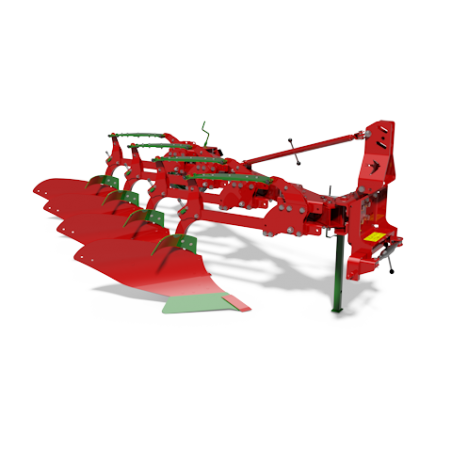

| Model | Working width (m) | Weight (kg)* Share bolt protection | Weight (kg)* Spring protection | Power demand (HP) | No. of furrows (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|---|

| PJ3 | 0.96 - 1.32 | 605 | 805 | 60 - 80 | 3 | 0.72 - 0.96 | 25 - 30 |

| PJ4 | 1.20 - 1.76 | 715 | 955 | 80 - 110 | 4 or 3+1 | 0.96 - 1.28 | 25 - 30 |

| PJ5 | 1.60 - 2.20 | 835 | 1035 | 110 - 150 | 5 or 4 + 1 | 1.20 - 1.60 | 25 - 30 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

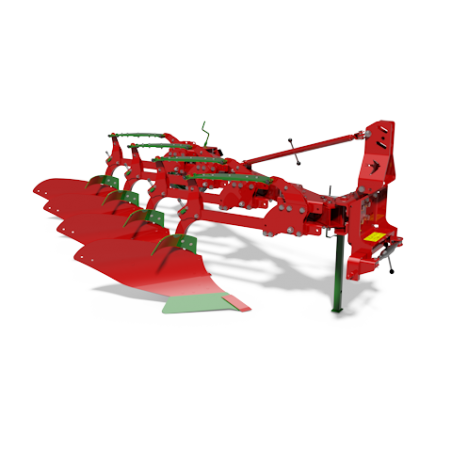

The single-beam ploughs of simple and robust design are ideal where the rotary ploughs do not need to be used. Appropriate clearance under the frame of 76 cm and body spacing of 85 cm or 100 cm guarantee coverage of even a significant amount of post-harvest residues and catch crops.

The single-beam ploughs require only the minimum adjustment. The machine does not need to be complicated in order to ensure the best ploughing quality. The limitation of the number of adjusting points to the necessary minimum is a huge asset which will be appreciated by every farmer who is strongly interested in shortening the working time. Engage the plough and be just ready for working.

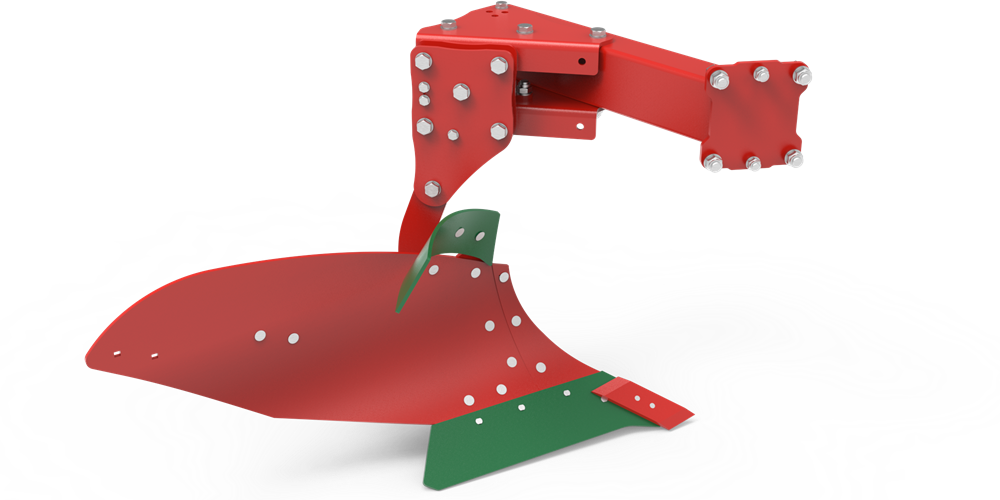

The strength characteristics of the subassemblies, such as ploughshares or mouldboards, including mainly their wear resistance, allow not thinking about their replacement for the long time. Every ploughshare is made of the best steel grade which provides the opportunity to work in the extremely heavy conditions.

The ploughing performance and tractor combustion level depend to a large extent on the working width of the plough. The ploughing width in our ploughs can be changed in a simple manner, by shifting the position of adjusting bolt which determines the work width of every furrow-slice. The working width of the plough can be adjusted to the tractor power and type without unnecessary efforts. The four-stage scale of the gradual work width adjustment of every body within 35, 40, 45, 50 cm gives huge opportunities. The width reduction can be forced by changing soil conditions. The width can be also increased to the maximum when shallow ploughing is required. The tractor power and parameters can be fully used in very changing conditions as well.

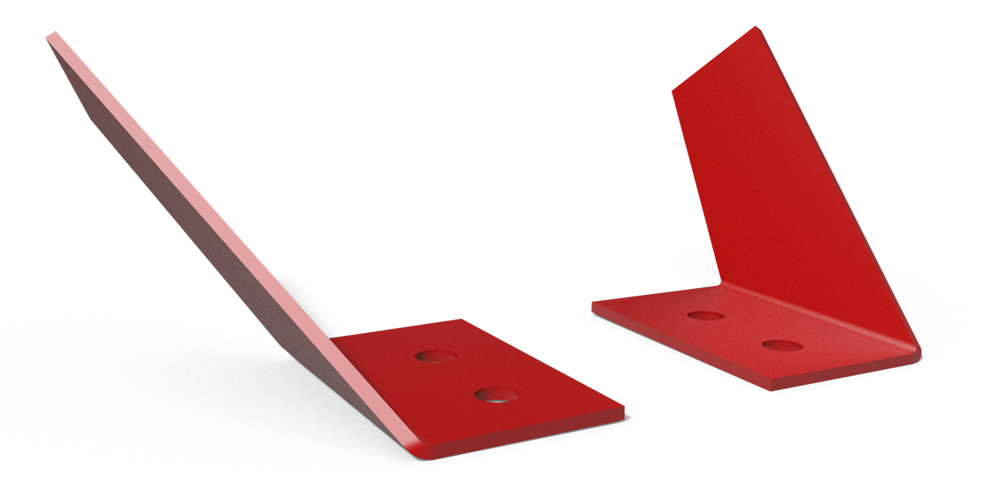

When plowing fallow land, meadows or pastures, extension slats mounted on mouldboards are extremely useful.

More and more often chosen by farmers as a cheaper replacement for the disc cut.

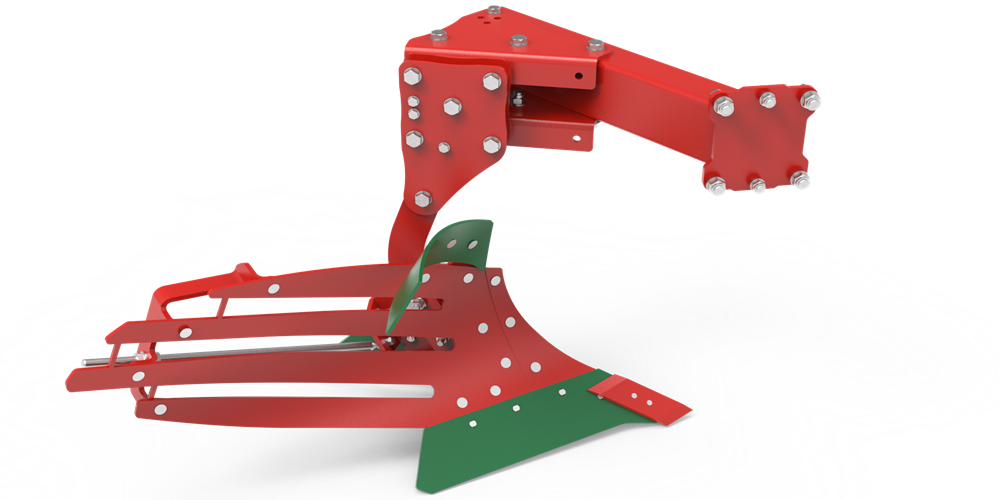

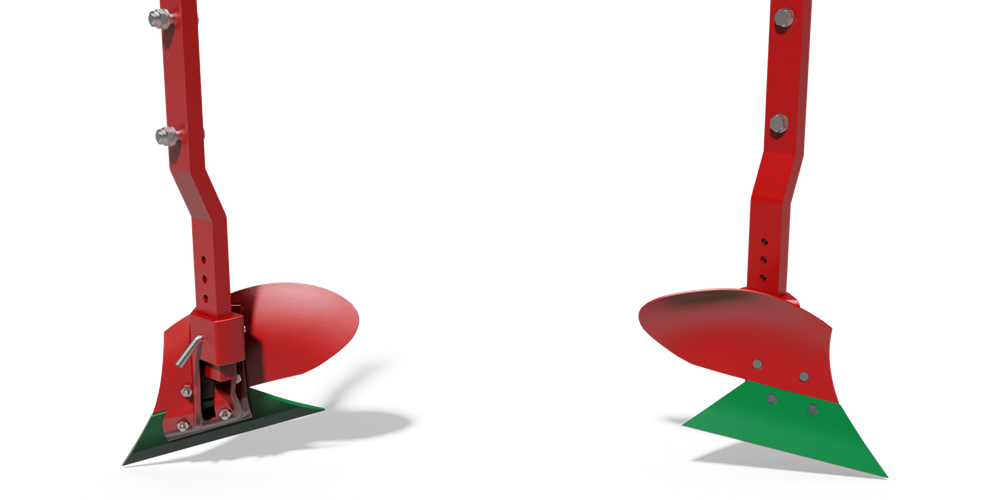

To achieve the fullest effect of mixing with the soil and covering crop residues, the plow can be equipped with a set of skimmers. Determining the optimal position of their work is possible thanks to multi-step adjustment. The position of the skimmers is easily changed by means of an adjustment screw, which blocks the position of the skimmer. Each skimmer has universal and popular overload protection in the form of a break screw. Each individual handle of the skimmer is mounted to the main body pocket, which guarantees that the working geometry of the skimmer will be identical to the work characteristics of the body on which it is mounted. Skimmers are particularly well suited to working on corn stubble. When the user decides that the use of shear bars gives a satisfying effect, he can quickly dismantle the skimmers and return to the previous configuration.

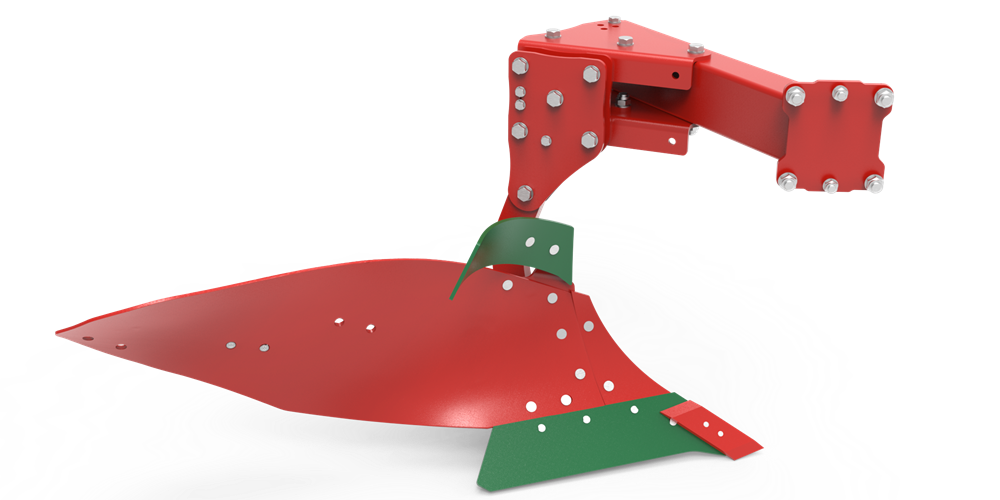

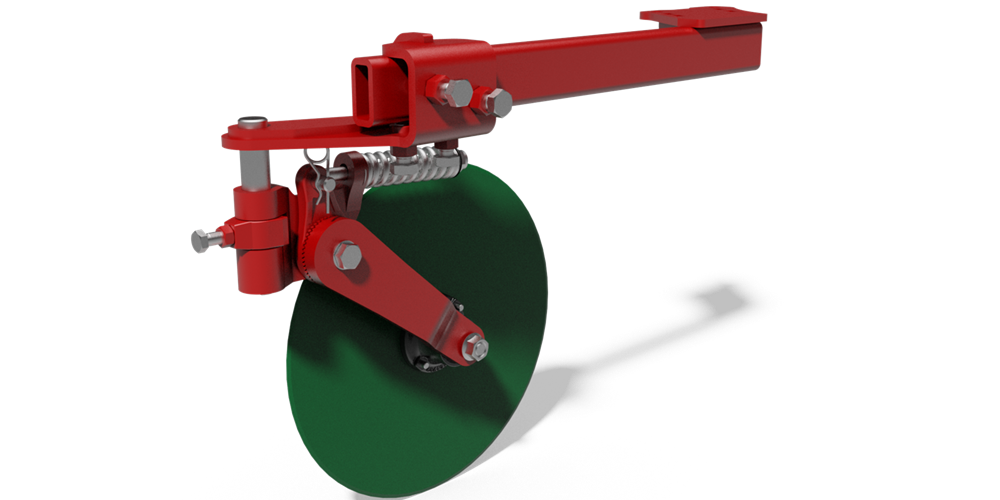

Corrugated discs with a diameter of 500 mm for both models with screw and spring protection significantly improve the visual effect of the plow. Cutting the furrow away, the disc coulters condition the furrows most accurately, leaving a clean furrow with smooth walls. The effect of covering crop residues is also increased by the effect of the typefaces. Like every working element, the cuts are also protected against exposure to harsh soil conditions. In this case, the role of the fuse is a spring with adjustable clamping force. On the other hand, toothed adjustment cubes help to obtain the optimal working position of the disc coulter.