Our machines

| Model | Width (m) | Weight (kg)* | Power demand (HP) | No. of tines (pcs) | Performance (ha/h) | Working depth max (cm) |

|---|---|---|---|---|---|---|

| AP21 | 2.1 | 760 | 65 - 80 | 5 | 1.47 - 2.10 | 15 |

| AP26 | 2.6 | 860 | 80 - 100 | 6 | 1.80 - 2.60 | 15 |

| AP30 | 3.0 | 960 | 100 - 140 | 7 | 2.10 - 3.00 | 15 |

* The given weight is approximate and may differ from the actual one, depending on the equipment and configuration.

Appropriately shortened design, simplicity of regulation and protection, high throughput, possibility of deep and shallow stubble cultivation - all these features indicate that our stubble cultivator perfectly fits into the concept of fast and intensive stubble cultivation. The spectrum of applications is really large.

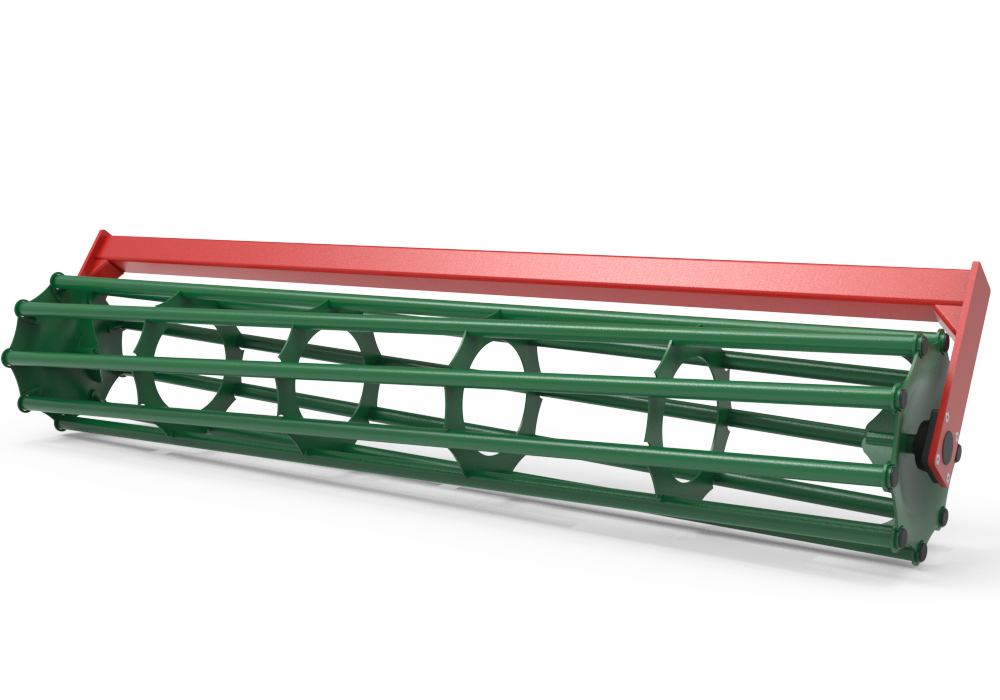

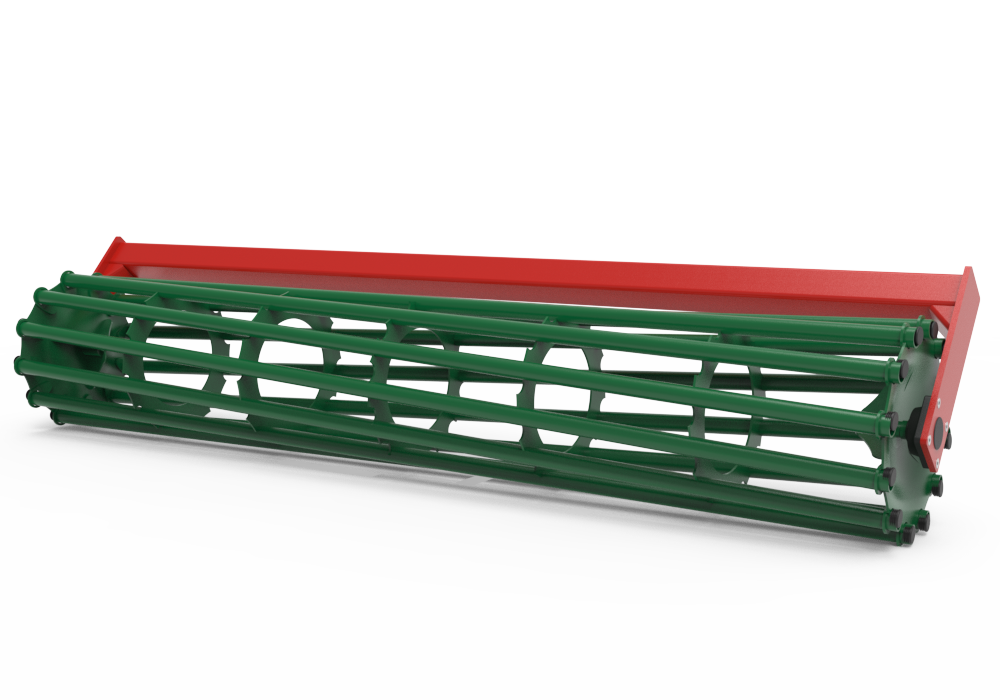

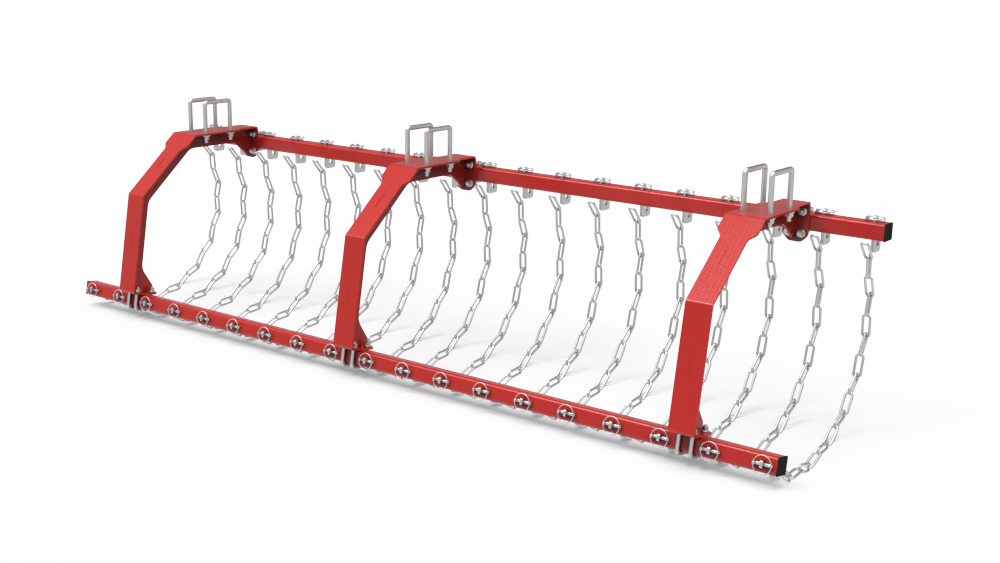

The harrow section is mounted in a system of four elastomers. This security system is known for disc harrows and works great also with wide disc spacing.

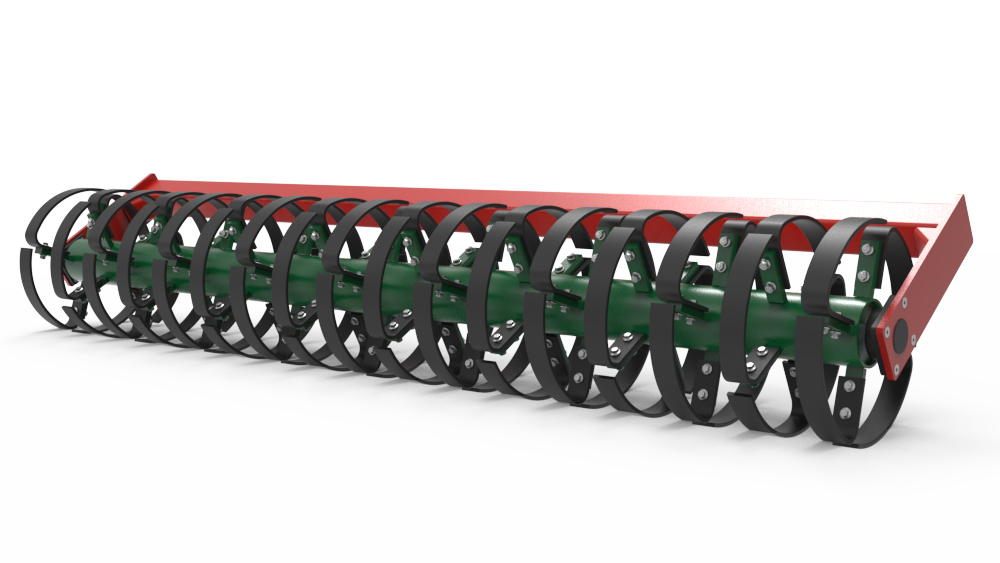

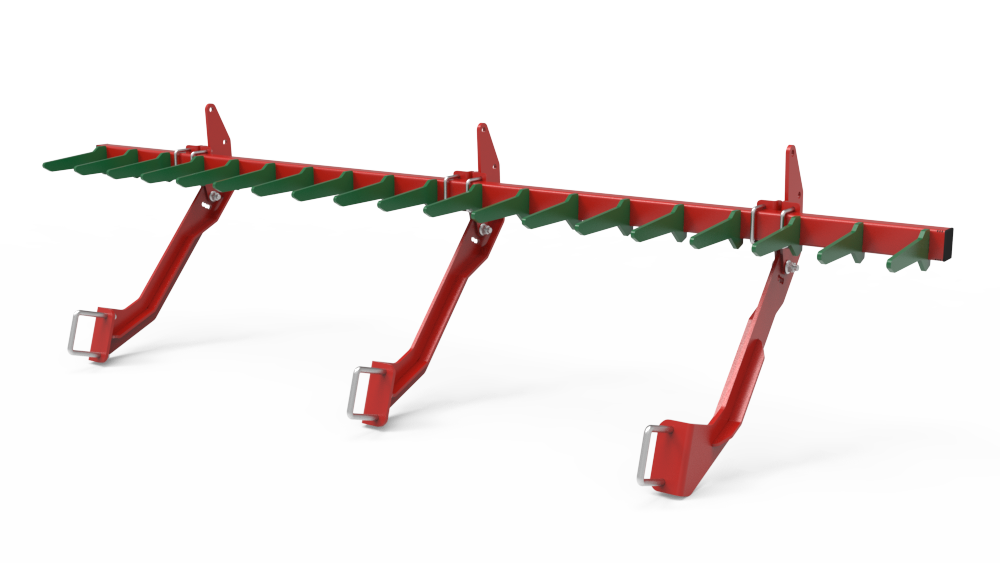

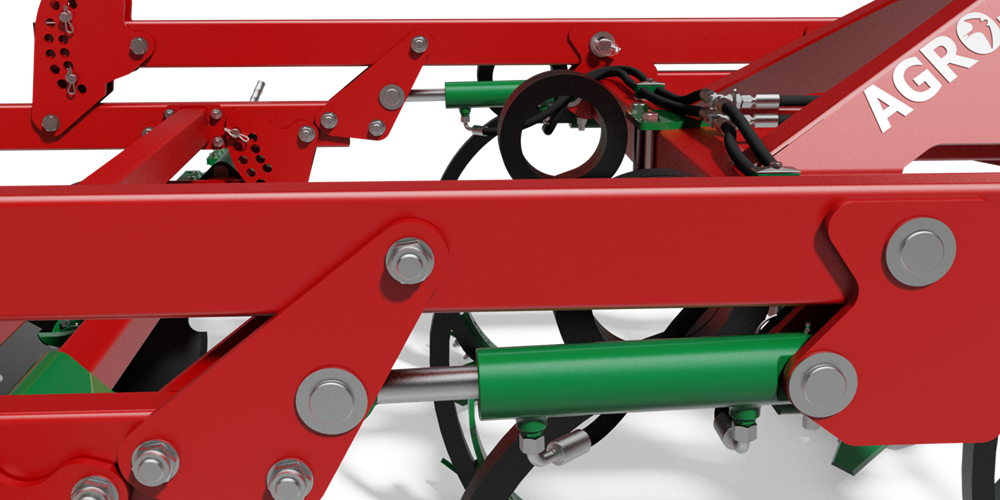

The combination of claws with wing coulters and twin shares, set at the right angle to the ground in two rows will allow for even, intensive mixing of crop residues without duplication of passes. Wing coulters are double-sided tools that allow longer use. Each coulter element is replaceable. Thanks to the right combination of distances between beams and ground clearance, they provide excellent results in both light and heavy soil conditions.

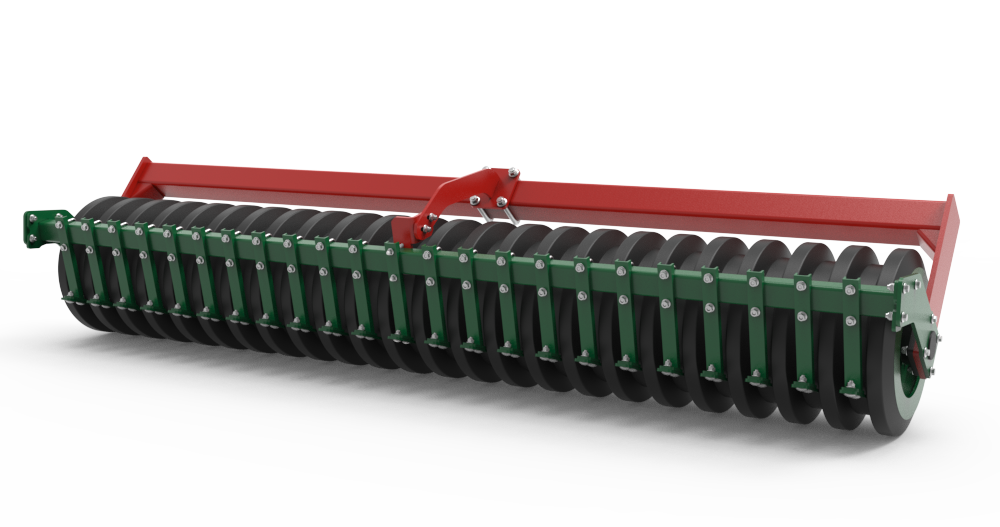

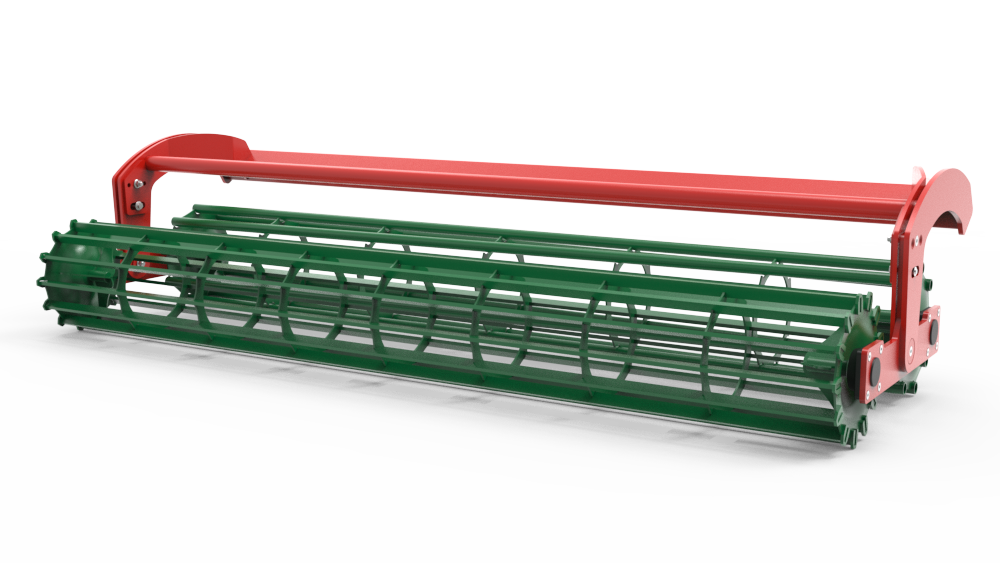

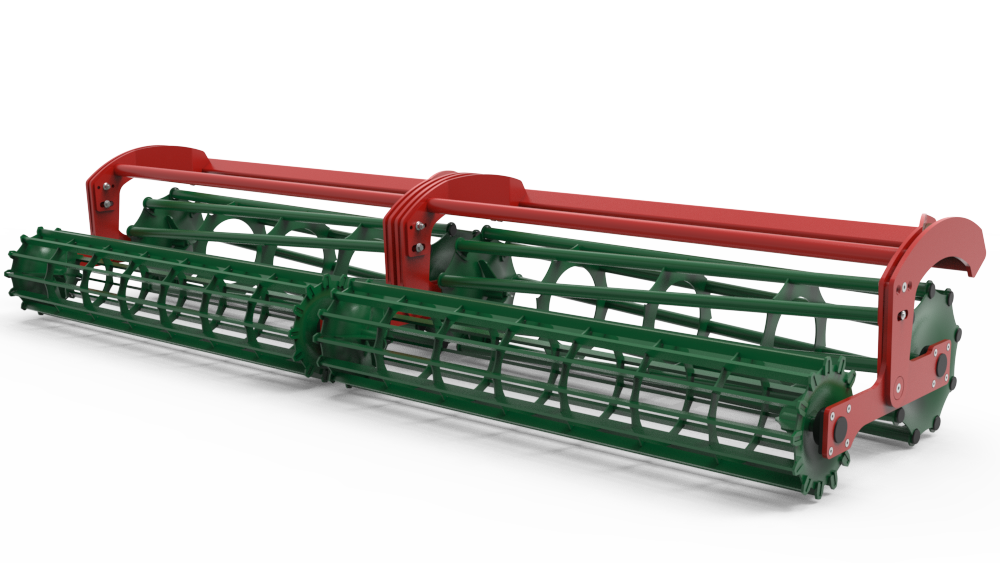

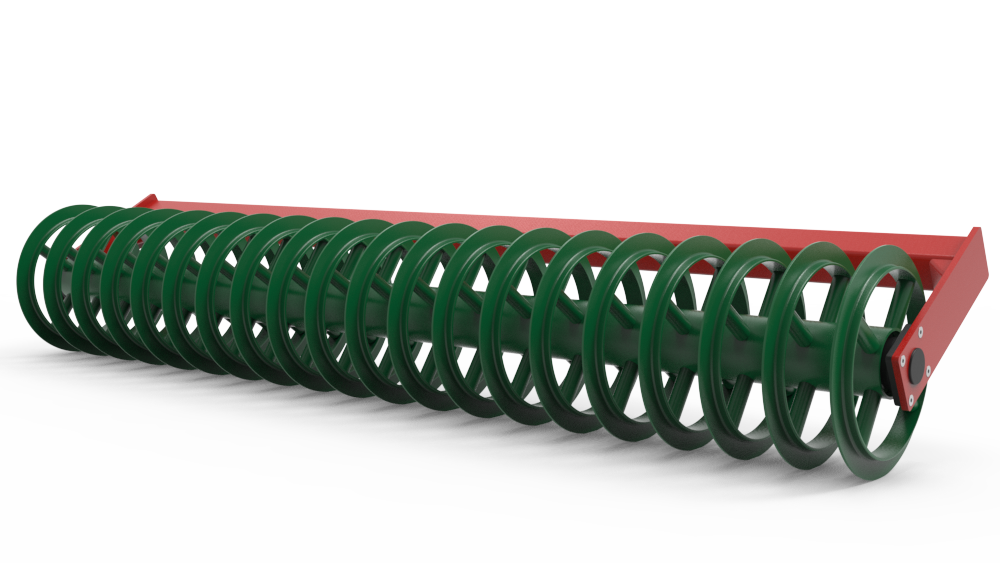

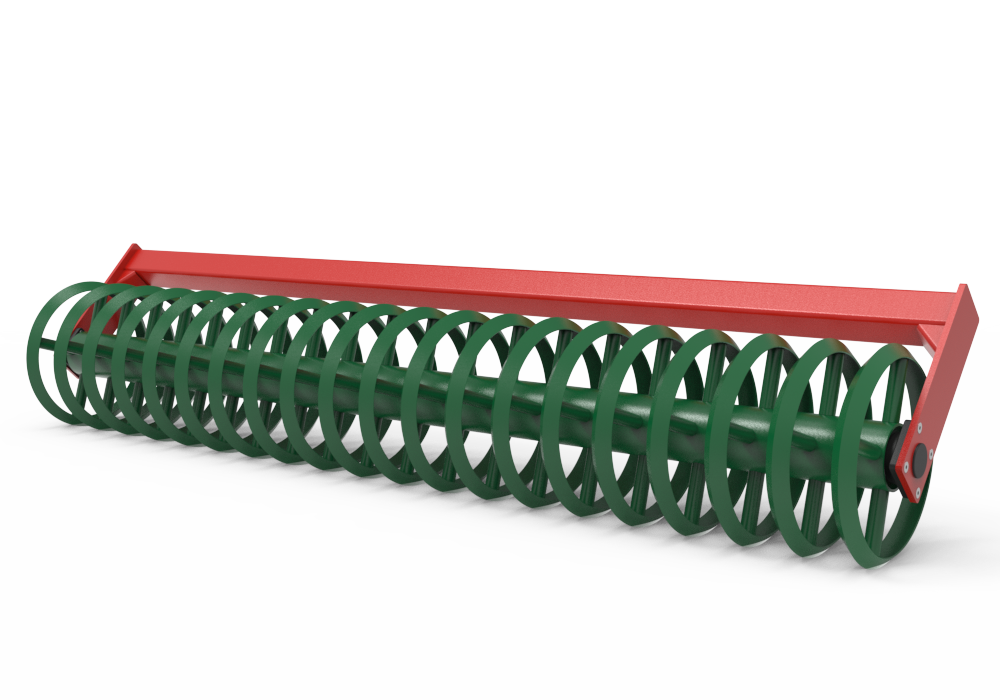

You will achieve the best leveling and compaction of soil by choosing a roller from a wide range of tillage rollers, suitable for different soil conditions. In addition to the properties resulting from its construction, the shaft performs another important function - the working depth on the shaft arms is adjusted at which the claws are to work. A simple arrangement of pins, whose position is changed in relation to the adjustment plates, allows to reduce claw penetration, taking into account specific soil conditions and the desired working speed. The adjustment system of the working depth of the discs is also innovative, which parameter is changed in relation to the position of the shaft. Thus, by changing the position of the shaft, we automatically change the working position of the cultivating plates.

The modern design of the frame allows the simultaneous adjustment of the depth of the discs and the shaft.